As AI and high-performance computing (HPC) workloads intensify, traditional air-cooling systems are struggling to keep up. With power demands exceeding 100kW per rack and air-cooling fans consuming up to 15% of server power, data centers are turning to more efficient solutions: liquid and immersion cooling.

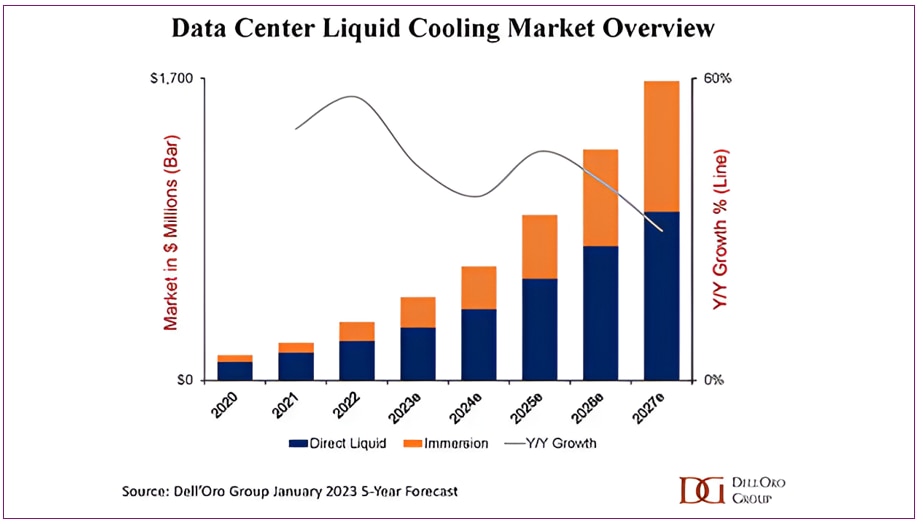

Dell’Oro Group predicts liquid cooling adoption will soar by the second half of 2024, creating a $15 billion market opportunity by 2028. Amphenol is at the forefront, offering advanced interconnect solutions tailored for these technologies.

Liquid Cooling: Unleashing Efficiency and Performance

Liquid cooling leverages the superior thermal conductivity of fluids—up to 3,000 times more effective than air—to manage heat in power-intensive systems. Coolant fluid is circulated through active or passive heat exchangers, often installed at the rear of the rack. This method, with its proven success in desktop gaming and workstation applications, is now being deployed at scale for data center racks, efficiently dissipating heat from critical equipment shelves.

Liquid Cooling: Efficiency in Action

Liquid cooling uses thermally conductive fluids to dissipate heat, performing up to 3,000 times better than air. This method is increasingly applied to racks and components like chips, where single-phase cold plates or two-phase evaporation units target heat at the source, removing up to 75% of generated heat.

For pluggable modules, Amphenol’s liquid-cooled OSFP and QSFP DD cages replace conventional heat sinks, delivering superior cooling and compatibility with market standards.

Immersion Cooling: Simplifying and Optimizing

Immersion cooling submerges servers or racks in dielectric fluid, eliminating air-cooling systems and reducing Power Usage Effectiveness (PUE) to as low as 1.01.

Single-Phase vs. Two-Phase Immersion Cooling

- Single-Phase Immersion Cooling: Equipment is surrounded by a high-boiling-point dielectric fluid that remains in liquid form throughout operation. The heated fluid is cooled and recirculated, creating an efficient thermal management loop.

- Two-Phase Immersion Cooling: This method utilizes low-boiling-point fluids that vaporize to capture excess heat. The vapor is condensed and returned as liquid, ensuring continuous heat dissipation.

Challenges in Connector Design

Immersion cooling presents unique challenges for interconnects. Submersion in dielectric fluids alters the dielectric properties around connectors, affecting signal integrity. Materials such as PCB composites, metallic plating, and solder joints must withstand prolonged exposure to these fluids without degradation.

Amphenol addresses these challenges with the ExaMAX2® ARK Connector, engineered specifically for immersion-cooled systems. This product maintains performance on par with the ExaMAX2® Series in air-cooled environments, ensuring exceptional signal integrity at higher frequencies.

EXAMAX2® ARK Product Line is a derivative product of the broadly adopted ExaMAX® Product Series and is mate and footprint compatible with EXAMAX2® Connectors.