by Shane O'Meara

This blog marks the second instalment in our ongoing series, delving into the fast-evolving landscape of industrial mobile robots. We initially examined how Industrial Mobile Robotics are revolutionizing the Factory of the Future Industrial Mobile Robotics - Revolutionizing the Factory of the Future Today - element14 Community

In this edition, we take a closer look at two key technologies shaping the future of mobile automation: Automated Guided Vehicle (AGVs) and Autonomous Mobile Robot (AMRs). While both AGVs and AMRs are designed to enhance efficiency and flexibility in industrial environments, they differ significantly in terms of navigation, adaptability and use cases. By examining their core similarities and distinctions, we aim to help you determine which solution best aligns with your industrial automation needs.

A mobile Automated Guided Vehicle (AGV) and an Autonomous Mobile Robot (AMR) share most of the same core fundamental attributes and will carry out similar automation tasks in an industrial application. The primary function for an AGV or an AMR is the transportation of materials from one location to another location in a factory or warehouse.

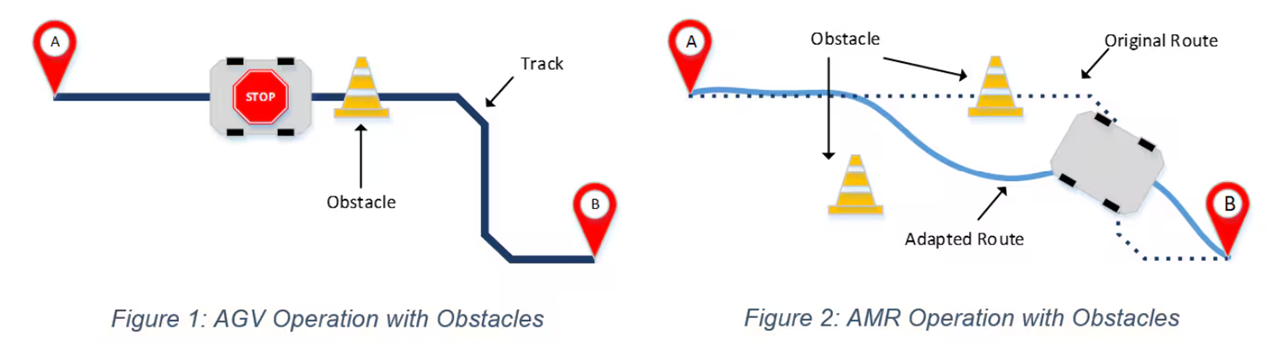

The fundamental difference between an AGV and an AMR is in their navigation capability and ability to avoid obstacles. An AGV follows a predetermined track or route and will not deviate from this path as it travels from one location to another. If an AGV detects an obstacle blocking the path it will stop and remain in place until the obstacle is removed. An AMR also has the ability to detect an obstacle but has the intelligence to adapt its route to avoid the obstacle, calculate a new route and proceed to complete its goal without user intervention.

An AGV can use different sensing techniques to detect its route.

- Magnetic tape stuck onto the factory floor. A corresponding sensor under the AGV detects the location of tape and adjusts its position. Additional pieces of magnetic tape can be used to code locations.

- Inductive wire embedded in the floor. Again, a sensor detects the wire and adjusts the AGV position accordingly.

- Visual tracking, colored tape or markers such as April Tags are placed on the ground and detected with RGB cameras to map route and determine location.

- Laser guided by a 360° laser mounted on the AGV and several reflectors installed in the facility. The AGV measures the distance and angle to the reflectors and triangulates its position.

The main advantage of AGVs is that they follow their predetermined route precisely and consistently hence making them ideal for high volume, repetitive tasks. Their main disadvantages are that they require infrastructural changes within the facility they intend to operate in and significant effort to setup and maintain. Tape, wire, markers or reflectors must be installed on the floor or walls and then maintained. Visual markers can be impacted by dirt or magnetic tape may become dislodged. Inductive wire is extremely robust but any adjustments have a significant impact on day to day operation as the floor must be redone. Additionally, as mentioned previously, they lack the ability to avoid obstacles so they stop operating if an obstacle is detected.

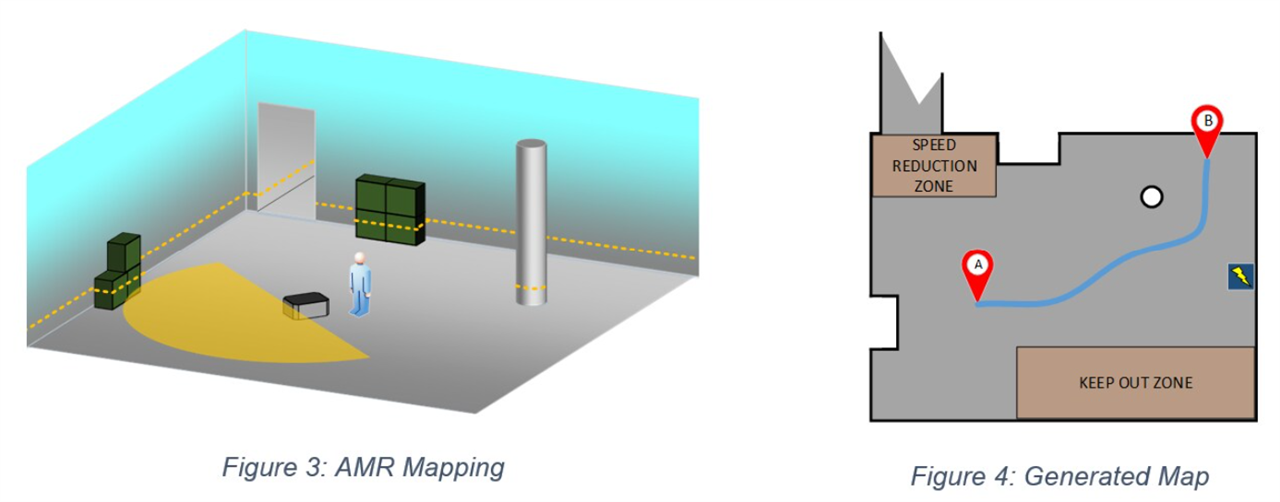

AMRs use Simultaneous Localization and Mapping (SLAM) to navigate the factory floor. Depth sensors, commonly Lidar scanners, mounted on the AMR are used to map the factory floor. The AMR is first driven around the facility and scans are accumulated to generate a complete map which is stored on the AMR and in fleet management control software. The generated map can be enhanced with additional information such as keep out zones, speed reduction areas and docking station locations. Goals can be placed on the map as x, y coordinates or dropped pins for the AMR to navigate between. During operation the most recent scan from the Lidar scanners is compared against the stored map and the current AMR position and orientation are calculated. The AMR then uses the built in navigation system to determine the optimized route to its goal considering the stored map and any obstacles it encounters on the path.

Disadvantages of AMRs compared to AGVs is that they have a higher initial cost and are less predictable than an AGV which takes a defined time to reach its goal. The obvious advantage of AMRs is that there is no requirement for infrastructural changes to enable their operation as an AMR has the sensing capability and intelligence to localize and navigate autonomously without markers. New tasks and goals can be updated within the map or fleet management software quickly and efficiently. Facility expansions and automation upgrades can be easily accommodated with the generation of new maps or extension of existing maps.

In the dynamic environments of the factory of the future, the ease of use, flexibility, scalability of an AMR gives it a clear advantage compared to AGVs. AMRs generally have enhanced sensing capabilities, with longer range Lidar, 3D depth sensing, radar and RGB vision technologies. These sensing modalities combined with superior compute power and artificial intelligence open up additional possibilities for advanced features and improved human robot interaction. To learn more on how ADI’s technology is enabling AMR and AGV robotic deployments, visit analog.com/mobile-robotics.