This blog looks at how motor control architectures and functions are evolving to meet the requirements of Industry 4.0 – from simple grid-connected motors to complex multi-axis servo drive solutions. This evolution has been accelerated by the increasing complexity of automation required to deliver the higher levels of productivity, flexibility, and autonomy required by the rapid digitalization of consumption, supply chains, and smart manufacturing [1]. The demand for agile production and greater access to production data have both contributed to the increasing complexity of motor control systems. The previous blog in this series looked at the importance of making motors more sustainable.

Agile Production

As industries are adapting to keep up with consumer demand and changing buyer behaviors, agile production, based on reconfigurable production lines, is required to deliver more customization and faster turn-around times. Consumer demand is driving a shift away from low-mix, high-volume manufacturing toward high-mix, low-volume manufacturing, which demands greater flexibility on the factory floor. Complex, repetitive, and often dangerous tasks can now be performed by industrial and collaborative robots, leading to higher throughput and increased productivity. This shift in production patterns has resulted in a higher demand for more complex, customizable, autonomous, and intelligent automation hardware, at the heart of which are motor control systems. For example, systems such as conveyors and handling machines are required to be smarter, have more axes of motion, and be highly configurable.

Access to Production Data

Global spending on digital transformation will reach $6.8 trillion globally by 2023 [2]. Variable speed drives can provide access to machinery data in the form of voltages, currents, position, temperature, power, and energy consumption combined with external sensors for monitoring vibration, and other process variables. With a converged information technology/operating technology (IT/OT) Ethernet network motor and machine data and insights are now more accessible and can be analyzed by powerful cloud computing and Artificial Intelligence (AI) to optimize manufacturing flows and monitor the current state of health of the assets across the entire installation. This optimization of manufacturing flows will further reduce energy consumption in smart manufacturing.

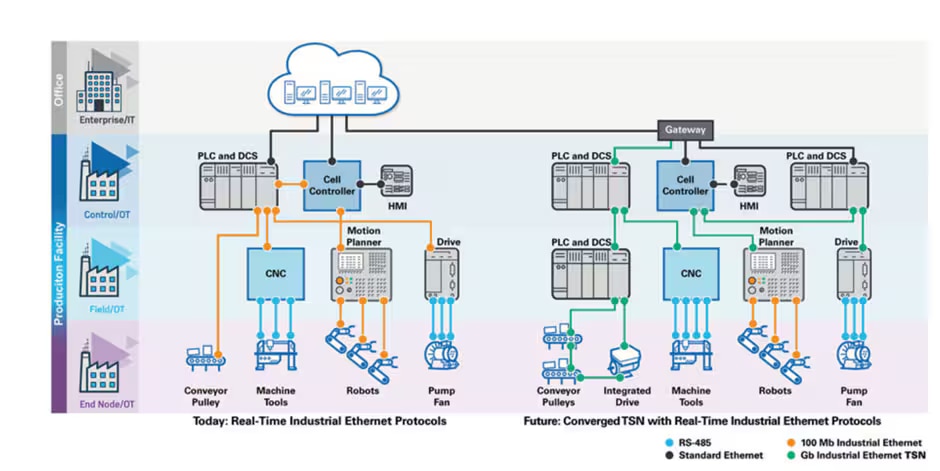

Figure 1: Digital transformation enabled by seamless Industrial Ethernet connectivity.

To deliver this, motion control systems are moving towards a converged connectivity scenario, where legacy, mixed Industrial Ethernet communication protocols are being gradually displaced by Time-Sensitive Networking (TSN)-based systems, standardized around the IEEE802.1 network standards [3], as illustrated in Figure 1. This will enable time-synchronized data from end equipment to be available across all areas of the network in real-time.

A Spectrum of Motor Control Solutions

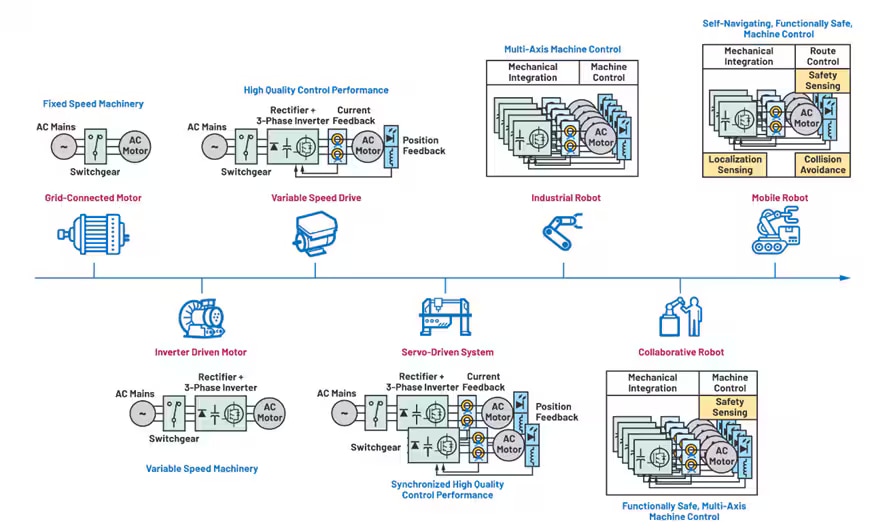

Ultimately, modern production systems will include a mix of simpler and more complex motor control systems, as those highlighted in Figure 2, with the grid-connected and simple inverter drives being replaced more and more by interconnected, sensor-integrated, synchronized systems. Each of these “flavors” of motor control is described briefly here, along with the applications served by them.

Figure 2: The range of motor control solutions used in modern automation

Grid-Connected Motor: These basic motion solutions run at a relatively fixed speed. True constant-speed applications are fairly limited in industry, but these will continue to be used in situations where motor operation is very intermittent, and the cost of a VSD is not justified (e.g. low power, intermittently used blowers, pumps, valves, actuators).

Inverter Driven Motor: The addition of a simple open-loop inverter to the motor control enables significant reductions in energy consumption by running the motor at the optimum speed for the load and application. Pumps, fans, blowers, and cruder control systems, such as platform movers are typical applications.

Variable Speed Drive: For higher-performance motion control applications, a variable speed drive (VSD) enables accurate torque, velocity, and position control. To achieve this, current and position measurements are added to the basic open-loop inverter drive. Conveyors, winding, printing, and extrusion machinery are typical examples of applications needing VSDs.

Servo-Driven System: Synchronized, multi-axis servo-driven systems are used in more complex motion applications. Machine tools and CNC machines require synchronization of multiple axes, with extremely accurate position feedback. Precision machining and additive manufacturing are key applications that utilize multi-axis servo drives.

Industrial Robot/Collaborative Robot/Mobile Robots: Industrial robots require multi-axis servo drives combined with mechanical integration and advanced machine control algorithms to achieve complex 3D spatial positioning. Collaborative robots (cobots) build on industrial robotic solutions by adding power and force limiting (PFL) and safety sensing to deliver functionally safe, multi-axis machine control where an operator can work safely alongside the cobot. Mobile robots add localization sensing and collision avoidance. The applications served by robotics systems are growing, from traditional automotive manufacturing to handling, palletizing, pick-and-place, packing, and logistics.

In the next blog of this series, we will begin to look into the architecture of the motor drive itself and start breaking it down into its subsystems and components.

References

[2] Shawn Fitzgerald, Daniel-Zoe Jimenez, Serge Findling, Yukiharu Yorifuji, Megha Kumar, Lianfeng Wu, Giulia Carosella, Sandra Ng, Robert Parker, Philip Carter, and Meredith Whalen. “IDC FutureScape: Worldwide Digital Transformation 2021 Predictions.” IDC, October 2020.