One of the best ways to ensure a MOSFET is functioning properly and meets specifications is to determine its characteristics by tracing I-V curves. There are a number of output characteristics requiring I-V tests; you can derive gate leakage, breakdown voltage, threshold voltage, transfer characteristics, and drain current all by simply tracing I-V characteristics and verifying the device is working as it should.

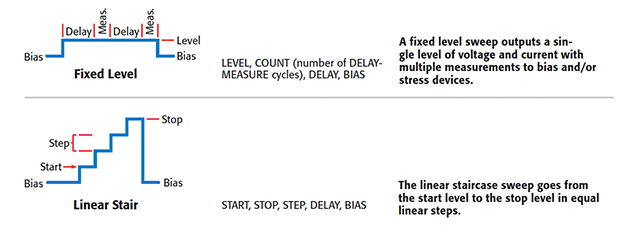

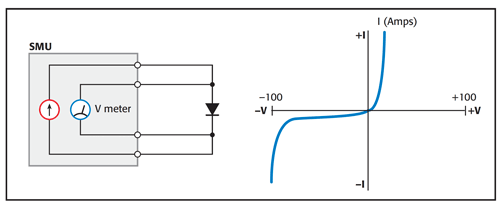

Keithley’s source measure units (SMU) are core instruments for MOSFET I-V characterization tests. Their ability to source voltage while measuring current or source current while measuring voltage can be combined with both DC and sweep operations to perform measurements such as forward voltage (VF), reverse leakage, and reverse breakdown voltage (VB) without changing a connection to the device under test (DUT) (Figure 1).

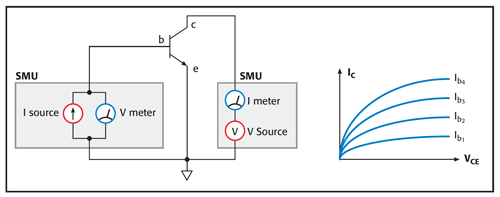

Using built-in features, multiple SMUs can be synchronized for parametric measurements like threshold voltage, beta, and transconductance.

Measuring I-V curves of a MOSFET with Keithley Source Measure Units

A family of MOSFET curves can be obtained with just two SMU instruments (Figure 2). For each base current from SMU1, SMU2 sweeps VCE and measures IC.

Pulsed I-V characterization, wherein voltages and currents are applied for a very short time and at a limited duty cycle, is another common way to measure I-V curves. Pulsed I-V measurements can reduce test times and allow for MOSFET characterization without exceeding its safe operating area or causing the device to self-heat and parameters to shift.

Two pulsed I-V channels are typically used to measure these MOSFET I-V curves with one channel connected to the gate and the other to the drain. The ground of each channel is connected to the MOSFET source pin.

To construct the transistor curves, the gate channel first applies voltage to the gate, then the drain channel sweeps VDS through a range of values, measuring the resulting current at each point. Next, the gate channel applies a different voltage to the gate and the process repeats, constructing the next MOSFET I-V curve in the set.

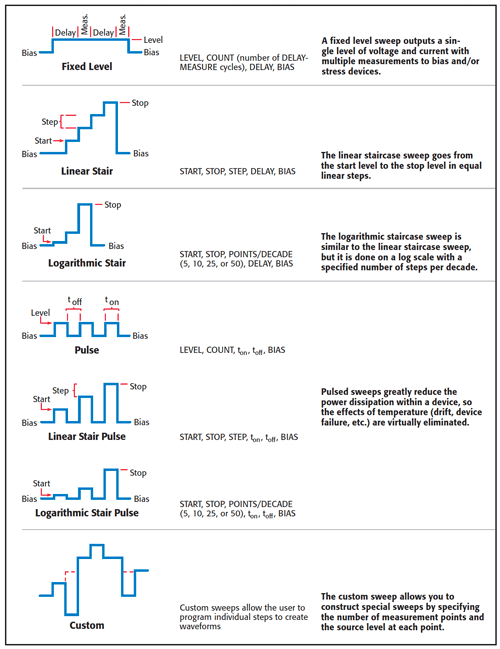

Keithley’s SMU instruments simplify this process with built-in pulsed and DC sweeps, including linear staircase, logarithmic staircase, and custom sweeps (Figure 3). Sweeps coupled with other throughput enhancements like built-in limit inspection, digital I/O, and a component handling interface are ideal for high-speed, non-stop production environments. All sweep configurations can be programmed for single-event or continuous operation.

Tektronix Keithley Instrument and software solutions for MOSFET I-V characterization

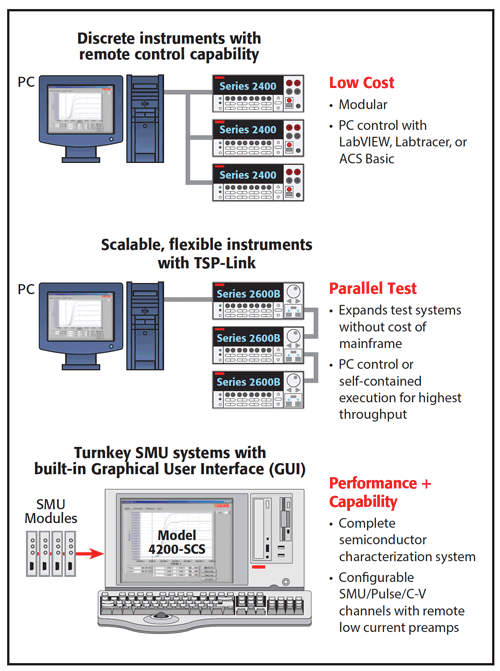

Figure 4 illustrates various hardware and software solutions for MOSFET I-V characterization. In the first example, Series 2400 SourceMeters are connected to a PC. In the second example, Series 2600B SourceMeters are connected with TSP-Link technology, which seamlessly integrates multiple SMUs into a single system that can be programmed and controlled as a single instrument through the master 2600B SMU or a PC.

Kickstart I-V characterizer software enables quick test setup and analysis, performs current versus voltage (I-V) testing on a variety of materials and devices, and can control up to four SMU instruments in each test

The third example uses the Keithley 4200A-SCS Parameter Analyzer. This system includes an embedded PC, Windows® operating system, and mass storage. It’s a complete signal characterization solution for FETs and test structures. It supports up to nine SMU modules and provides an array of Windows-based software that is so intuitive, even a novice can use the system with ease. This point-and-click software supplies a full range of functionality, including managing tests, generating reports, automating test sequencing, and creating user libraries. The Model 4200-SCS is a complete one-box solution that combines sub-femtoamp resolution with real-time plotting and analysis.

Engineers also have the option of combining any Keithley SMU with I-V curve tracer software to perform I-V curve tracing and characterize two-pin devices like diodes. If you need help finding the solution that’s most appropriate for your needs, contact the experts at Tektronix.