Welcome to the Murata page on element14. Here you can find things such as our latest news, training videos, and product details. Additionally, you can engage with us in our forums.

Market Trends

Expansion of the xEV market and power electronics

Technology Trends

SiC power semiconductors, integration technology, high voltage

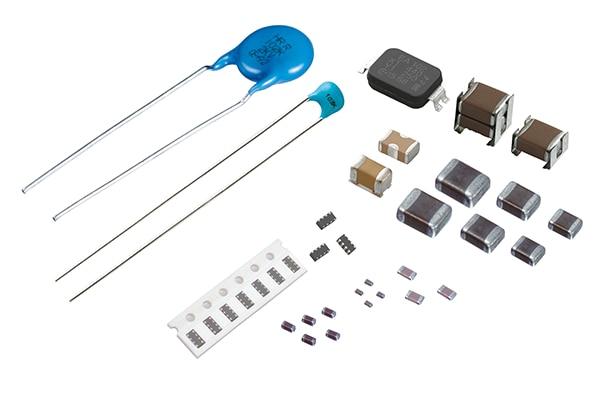

γ Capacitors

Suppression of high-frequency noise

Snubber Capacitors

Suppression of high-voltage surges

Thermistors

Improved implementation flexibility due to high temperature and high insulation voltage

This webinar "Basics of Ceramic Capacitors" is designed for engineer beginner. It will provide a comprehensive introduction, ranging from basic knowledge to practical applications. Through this webinar, you can get basic knowledge of Ceramic Capacitors role and functions in circuits. Focusing on the essential roles, characteristics, and utilization methods of Ceramic Capacitors in circuit design, participants will gain an understanding of the importance of Ceramic Capacitors and acquire knowledge that can be applied to their design work.

Please fill out the form, and you can watch on-demand webinar and download the presentation.

https://www.murata.com/en-eu/webinars/mlcc-1st-basic

Ceramic Capacitors

Murata offers the No. 1 most abundant lineup in the industry, responding to all possible needs, and proposing ideal solutions.

Continuing to evolve as the world's No.1 manufacturer of Ceramic Capacitors.

HDMI is a digital interface using differential signaling that was designed for the transmission of digital video and audio. It is widely used throughout the audio-visual market. HDMI 2.1 is an extension of HDMI 2.0, and it supports speeds that are twice as fast as HDMI 2.0.

HDMI is a digital interface using differential signaling that was designed for the transmission of digital video and audio. It is widely used throughout the audio-visual market. HDMI 2.1 is an extension of HDMI 2.0, and it supports speeds that are twice as fast as HDMI 2.0.

HDMI 2.1 has a maximum bandwidth that is about 2.7x that of HDMI 2.0, and its maximum signal transmission speed per lane is twice that of HDMI 2.0.

Whereas HDMI 2.0 consists of three data lanes and a clock lane, HDMI 2.1 does not have a clock lane, and it consists of four data lanes.

| HDMI2.0 (conventional standard) | HDMI2.1 (new standard) | |

| Maximum data rate | 18 Gbps (6Gbps/lane ×3) | 48 Gbps (12Gbps/lane ×4) |

|---|---|---|

| number of lanes | data 3 lane clock 1 lane |

data 4 lane clock 0 lane |

| connector, cable | specified by the conventional standard | new (category 3) upward compatibility |

| receiver equalizer | must | must |

In this way, HDMI 2.1 transmits signals faster than before, and so care must be taken to ensure that the signal quality is not harmed when implementing noise suppression measures.

Two noise issues are conceivable when HDMI communication is performed.

Radiation noise ①:

Noise originating from HDMI interferes with the Wi-Fi antenna inside the equipment, reducing the Wi-Fi communication sensitivity (Intrasystem EMC)

Radiation noise ②:

Noise is radiated from the HDMI equipment or cable (Emissions)

This study focuses on the intrasystem EMC of radiation noise ① and examines corrective actions for it.

If normal noise filters are used for high-speed differential signaling lines like HDMI, the signal quality will deteriorate, and the signals will not be transmitted properly. For this reason, common mode choke coils (CMCC) are a suitable solution. Because HDMI signals are high speed, we should select a CMCC that is best suited for high-speed signals.

CMCCs are installed near the output pins of the IC at the HDMI source side and near the connectors at the sink side. The source-side CMCC installed near the IC can suppress the common mode noise generated from the transmission ICs at the source side by preventing the propagation of common mode noise at the sink side.

The sink-side CMCC can suppress the common mode noise generated from the HDMI signal wiring of the sink equipment by preventing common mode noise from entering the Wi-Fi antenna.

| DLM0NSB120HY2 |  |

| DLM0QSB120HY2 High common mode impedance and superior noise suppression performance |

|

| NFG0QHB542HS2 Extremely small effect on signals |

|

First, we verified how much HDMI communication affects Wi-Fi. We confirmed that, when HDMI 2.1 communication was started, the Wi-Fi reception sensitivity dropped by 6 to 10 dB in the 2.4 GHz and 5 GHz bands. When noise actually entering the Wi-Fi was confirmed, we found that it overlapped with the 2.4 GHz and 5 GHz bands.

Mounting of CMCCs (DLM0NSB120HY2) showed an improvement of 3 to 4 dB.

Next, we examined noise suppression measures for radiation noise.

First, we checked for any differences in the noise spectra for HDMI 2.0 and HDMI 2.1.

This showed us that higher frequency noise occurred in HDMI 2.1.

Mounting a CMCC (DLM0NSB120HY2) to the source side enables removal of HDMI 2.1 noise.

Radiation noise is still left after using a CMCC, but most of this noise was radiation noise of the DRAM installed separately on the board of the source equipment.

The eyemask test for HDMI 2.1 showed that the signal waveform was identical even after using CMCCs.

The AC common mode noise was reduced by 47% by using CMCCs.

An issue arose where the Wi-Fi reception sensitivity dropped during HDMI 2.1 communication, but this was improved by using CMCCs.

In HDMI 2.1, radiation noise occurred in the range from 1 GHz to 6 GHz, but this was improved by using CMCCs.

Inserting CMCCs had no effect on the eyemask test.

Use of CMCCs reduced the AC common mode voltage.

Are you looking for temperature sensing and compensation solutions in circuit design? NTC thermistors have temperature sensing (for prevention or control) and temperature compensation (correction) features. PTC thermistors have temperature sensing (for prevention) and current control (protection) features. Discover the perfect NTC/PTC thermistor for your specific needs by watching these informative videos.

*NTC thermistors have temperature sensing (for prevention or control) and temperature compensation (correction) features. This video explains the type of NTC thermistor to choose for each feature.

*PTC thermistors have temperature sensing (for prevention) and current control (protection) features. This video explains the type of PTC thermistor to choose for each feature.

The PoC (Power Over Coaxial) method is becoming more popular as high-speed in-vehicle interface. The bias-T circuit is required at the PoC, and the inductors must be selected to pass the criteria. Murata’s “Bias-T Inductor Design Support Tool” solves the issue - the optimal products and combination for PoC bias-T inductors can be found by simple operations.

Click herehttps://www.murata.com/en-eu/tool/bistto jump to the tool!

The SPMxx series of encapsulated DC-DC converters are highly reliable and designed for harsh environment applications with 88% efficiency Designed specifically for use in electronic equipment that will be subject to harsh environments such as outdoor communications, applications with little or no forced air cooling, smart grid and industrial process control equipment. The SPM15 series was designed for applications that require Vin ranges of 9-36V or 18-75V @ 15W. The SPM25 series covers

applications that require Vin = 36-75V @ 25W.

The SPM15 & SPM25 series provides single output voltages of 3.3, 5 or 12 VDC. In addition, the SPM15 has a 15 VDC output option. The SPM15 is available with two wide input range options of 9 – 36 VDC or 18 – 75 VDC. The SPM25 accommodates an input range around a 48 VDC nominal from 36 – 75 VDC. The operating temperature range is from – 40 degrees C to + 85 degrees C, designed for use in the most demanding environments.

These compact, 5-sided shielded, encapsulated converters, measuring 1” (25.4) x 1” (25.4) x 0.41” (10.41) mm offer an industry standard footprint, incorporate the latest PWM technologies, automated assembly processes and synchronous rectification techniques to achieve one of the industry’s highest energy efficiency ratings of 88%. A thermally conductive encapsulation material greatly improves the thermal performance in applications where there is little or no airflow, provides a stable platform for

environments where dirt & dust, vibration or extreme temperature variations are likely to occur during normal operation.

Protection features include over-current, over-temperature and under-voltage lockout. Basic insulation provides input to output isolation of 1,600 VDC.

The SPM series provides systems design engineers with a contemporary solution for the most demanding, high reliability applications. The SPMxx series can be used as a means to address the growing requirements for dc/dc converters designed for the most sever commercial applications.

Murata Power Solutions will be exhibiting at electronica in Munich, Germany, from 9-12 November 2010, booth B5:107.

For the first time, we will be part of Murata’s stand in the passives hall (B5). Visitors will be able to see a demonstration from Murata Girl, the unicycling robot, and technical experts from both Murata and Murata Power Solutions will be on hand to answer any questions about our extensive product offering.

Visitors will be able to see a demonstration of the unicycling robot, Murata Girl!

More information: http://www.murata-ps.com/electronica/

Watch a short tutorial to learn about our low EMI converter transformers approved for use with Analog Devices transceivers: www.brainshark.com/murataps/782482tx

View 782482 Series data sheet: http://www.murata-ps.com/datasheet/?http://www.murata-ps.com/data/magnetics/kmp_782482.pdf

Murata Power Solutions is proud to be a finalist in EDN magazine's 20th Annual Innovation Awards Competition. Our OKL series has been selected from hundreds of nominations to be a finalist for this year's awards. If you can take a few minutes to review the nominations, we would appreciate your vote. And you might find the OKL is a great fit for your point-of-load application.

Instituted in 1990, the Innovation Awards honor the people, products, and technologies that have shaped the industry over the past year. Nominees must have demonstrated innovation that resulted in a significant advance in technology and/or product development during the past 12 months, and the OKL design did just that!

The key design feature of the Okami OKL range of PoL DC/DC converters is the innovative iLGA (inspectable land grid array) package, which features small plated cut-outs (castellations) that allow easy access for visual inspection as well as test probe access to all pads. The iLGA package overcomes problems associated with testing and inspecting conventional LGA packages. It also supports greater reliability in customer PoL applications.

Click here to find out why the iLGA deserves to win...