180°C specified – What does it really mean?

Panasonic Power Inductors are specifically designed for harsh environmental conditions in engine, transmission, braking systems and powertrain applications. The target was from the beginning to develop a product that is very resistant to vibration and temperature. The result was the ETQP Series, which achieved this goal and set a new quality standard for automotive metal composite power inductors. As for vibration resistance we already gave deeper insights, this time we want to focus on temperature resistance of the Panasonic ETQP Series. As there is an increased number of applications which require a maximum temperature resistance of 180°C, there are also Power Inductors introduced to the market which state a temperature resistance of up to 180°C. But what does actually stand behind such a specification with the unclear definition of up to?

ETQP Power inductor design

To understand the impact of temperature on a power inductor we first want to take a look at the components and materials which the ETQP series is made up. The core consists of metal composite powder which is bound by a proprietary heat resistant binder system. The metal core material has a curie temperature of over 500°C, the core binder material has a heat resistance of over 200°C. The wire wound coil inside which is placed inside the core has a high quality amide imide wire coating material which is heat resistant over 200°C. All components were deliberately chosen with highest quality available in the market.

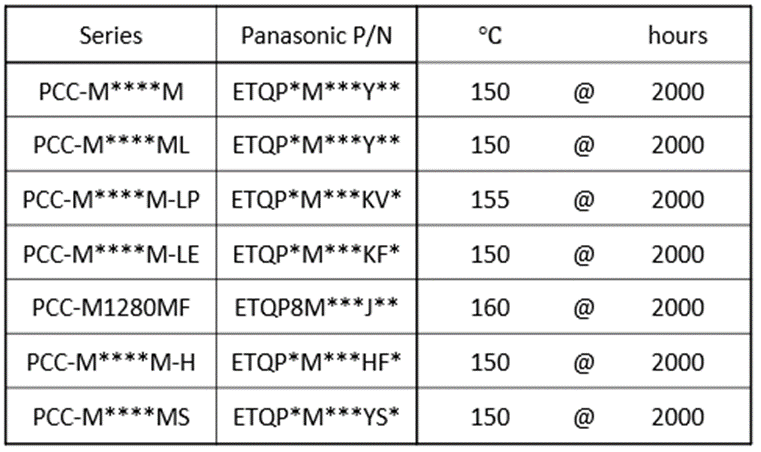

Specified temperatures

After the detailed explanation of the temperature robustness of each single component we can take a look at the temperatures of the standard endurance specification. The table below shows the specified temperature resistance of 150°C, 155°C and 160°C for a duration of 2000 hours, depending on the series.

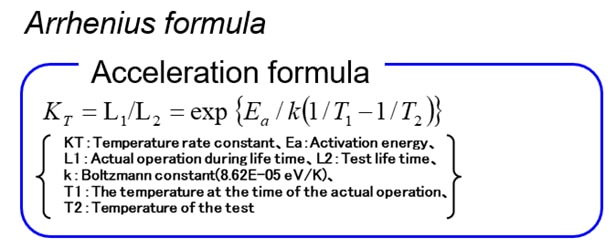

But that does not automatically mean that the power inductor is being destroyed when the specified temperature is exceeded. In fact each ETQP Power Inductor can handle even 180°C for a certain period of the specified lifetime. But this extraordinary temperature stress has an negative impact on the total lifetime which can be guaranteed for the product. This impact can be calculated by the Arrhenius formula and life time temperature profile, which we want to take a deeper look at now.

Lifetime vs Temperature

The following graph shows the relationship between lifetime and temperature stress of an ETQP inductor which has a specified temperature of 150°C. It shows an example of an application profile which exceeds the specified temperature by 30°C for 10 hours of its lifetime. The impact can be calculated with help of the Arrhenius formula. In case of this scenario, the guaranteed product lifetime of 2000 hours is being reduced to only 1750 hours at 150°C plus 10 hours at maximum 180°C. Than it has to be looked into the required overall lifetime of the power inductor to evaluate if the remaining lifetime still matches the requirements of the application.

Conclusion

As with many other data in the specification sheet of a power inductor, there has to be a deeper look behind what is presented at first sight. Even if a temperature resistance of 180°C is declared, it is not clear for how long the product can resist this temperature and what is the impact on the overall lifetime of the component. Panasonic intentionally does not state a temperature resistance of up to 180°C of the ETQP Series, as this information would be misleading without a deeper look into the overall temperature profile of the target application. However due to the high quality materials and design of the product, it definitely can be used for applications which require a temperature resistance of up to 180°C for a limited period of time. The product engineers from Panasonic will be happy to help you with detailed information and guidance if you need support in such a case.

To learn more, please visit our website: