Introduction: The Global Shift Toward Electrification

The electrification of vehicles, once a regional initiative led by European nations to combat climate change, has now become a global movement. Governments worldwide are implementing policies that mandate the exclusive sale of electric vehicles (EVs) within the next few decades. This rapid transition is driving innovation in EV design, particularly in the optimization of battery systems and electronic components.

EVs rely entirely on battery power—not only for propulsion via main motors but also for auxiliary systems such as steering, power windows, door mirrors, control units, and communication modules. As a result, the demand for highly reliable, compact, and efficient electronic components has surged.

Despite improvements in battery technology, EVs still face challenges in achieving long driving ranges. This makes the role of inverters and Battery Management Systems (BMSs) increasingly critical. Inverters convert DC output from batteries into AC for drive motors, while BMSs monitor and maintain battery health over time, minimizing degradation and ensuring long-term performance.

Panasonic Chip Resistors: Meeting the Demands of Modern EVs

Panasonic’s chip resistors are engineered to meet the stringent requirements of EV applications. With features such as high voltage tolerance, thermal stability, and precision resistance, these resistors are trusted by leading manufacturers for use in critical systems like BMS and operational amplifier circuits.

This article highlights two real-world examples where Panasonic chip resistors have been successfully adopted to improve performance, reduce component count, and enhance reliability.

Application 1: Voltage Monitoring in BMS Circuits

Challenge: High-Voltage Monitoring in Compact Spaces

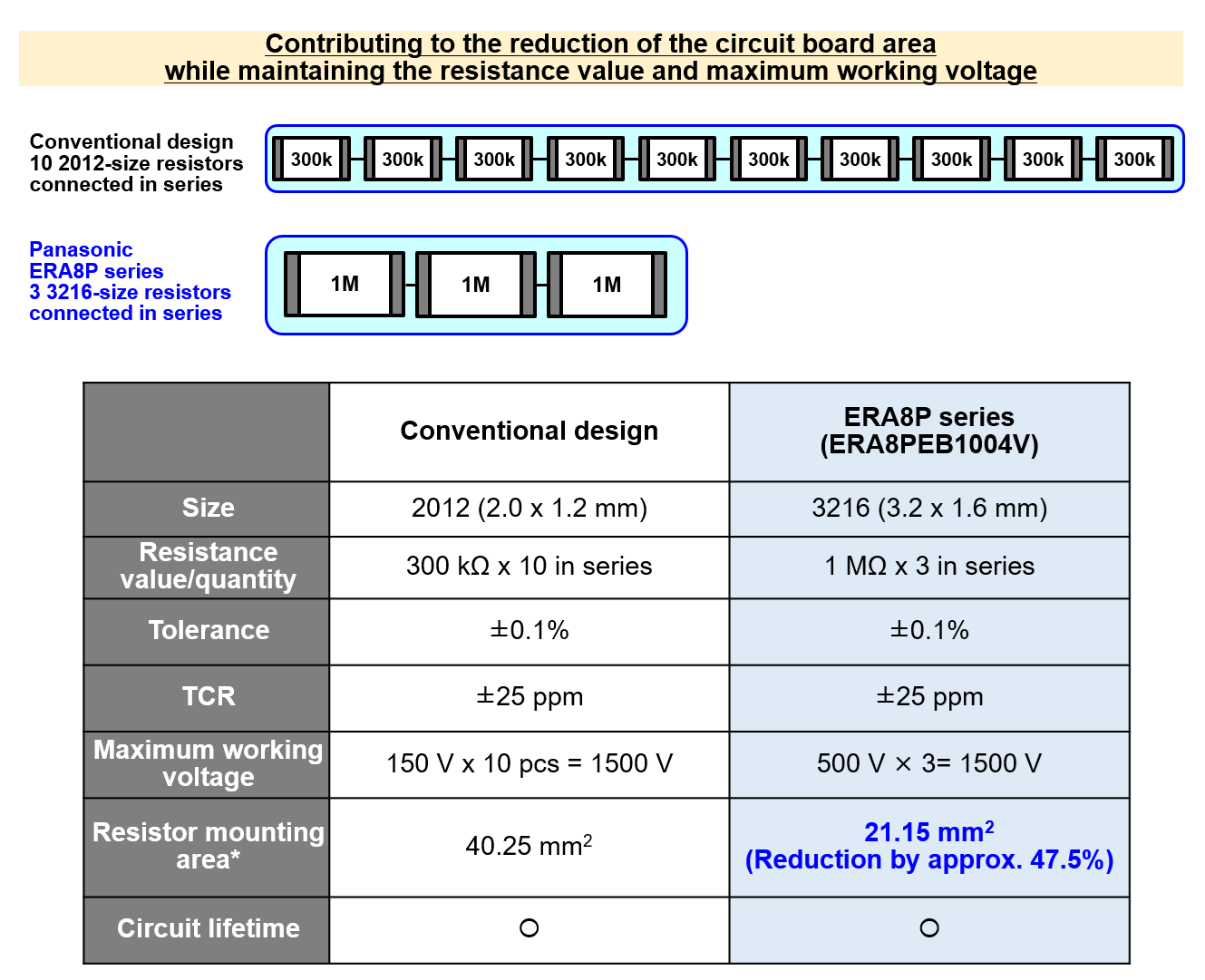

EV battery packs are constructed by connecting multiple modules of small cells to achieve high-voltage output. For instance, one customer utilizes a battery system with a maximum operating voltage of 1500 V. In their conventional BMS voltage monitoring circuit, they employed ten 2012-size (2.0 × 1.2 mm) thin-film resistors, each rated at 150 V and 300 kΩ, connected in series.

Solution: Panasonic ERA8PEB1004V Thin-Film Resistors

To improve space efficiency and reliability, Panasonic proposed replacing the ten resistors with three 3216-size (3.2 × 1.6 mm) thin-film resistors rated at 500 V and 1 MΩ (Model: ERA8PEB1004V). This change reduced the mounting area from 40.25 mm² to 21.15 mm², achieving a 47.5% reduction in board space.

Technical Advantages

- High Precision: ±0.1% tolerance and ±25 ppm temperature coefficient (TCR)

- Long-Term Stability: Designed to maintain accuracy over extended periods

- Stress-Absorbing Design: Proprietary materials and structure reduce solder cracks caused by thermal contraction

- Superior Reliability: Maintains connection integrity even in high-stress environments

Panasonic’s design addresses a common issue in long-term use—solder cracking due to thermal mismatch between the PCB and mounted resistors. While larger resistors typically experience greater stress, Panasonic’s thin-film resistors outperform competitors in connection reliability, regardless of size or film type.

Impact on Battery Health Monitoring

The high accuracy and stability of these resistors enable precise monitoring of battery degradation. This contributes to early detection of anomalies, enhancing the safety and longevity of EV battery systems.

Application 2: Operational Amplifier Circuits in EVs

Challenge: Precision and Miniaturization in Amplification Circuits

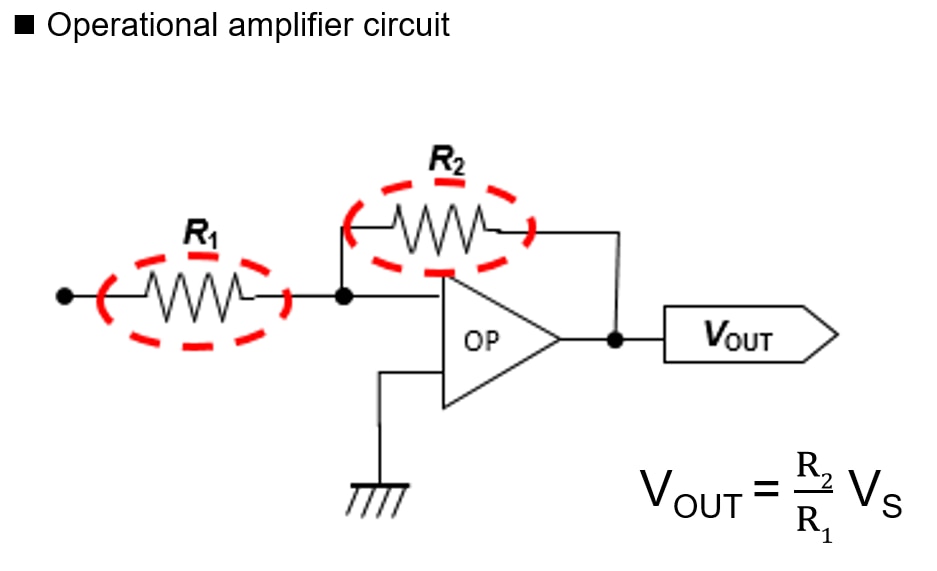

Operational amplifiers are widely used in EVs to boost battery voltage to required levels. The amplification factor is determined by the ratio of two resistors (R1 and R2), making precision a critical requirement. Unlike BMS circuits, these resistors do not require high voltage tolerance but must maintain exact resistance values.

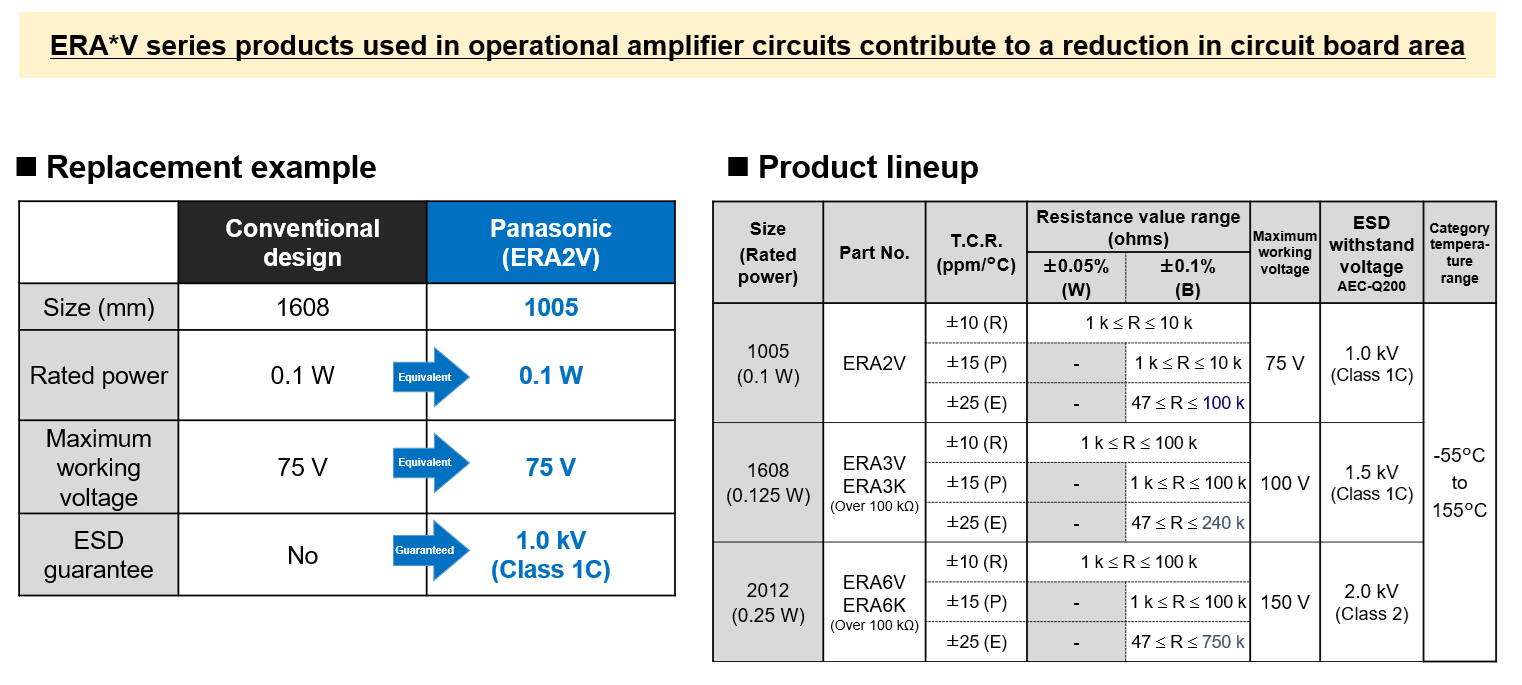

Solution: Panasonic ERA2V Series Thin-Film Resistors

Panasonic’s ERA*V series offers compact, high-precision resistors ideal for amplifier circuits. For example, replacing a 1608-size (1.6 × 0.8 mm) resistor with a 1005-size (1.0 × 0.5 mm) ERA2V series resistor—both rated at 0.1 W and 75 V—results in a 60.3% reduction in mounting area.

ESD Protection and Industry-Leading Durability

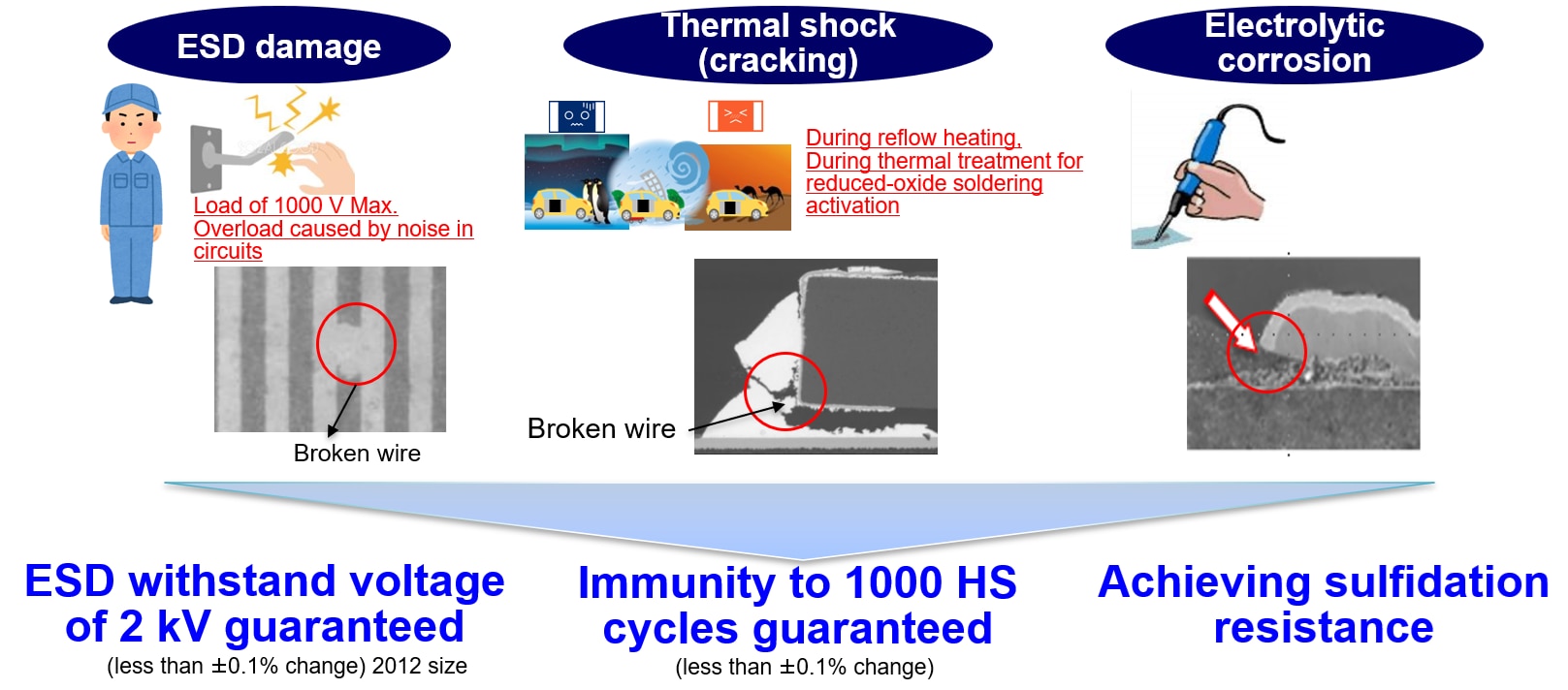

Thin-film resistors are generally more vulnerable to electrostatic discharge (ESD). Panasonic’s ERA*V/K/P series incorporates robust ESD protection:

- 2012 size: Withstands up to 2 kV

- 1608 size: Withstands up to 1.5 kV

- 1005 size: Withstands up to 1.0 kV

These values are among the highest in the industry (as of March 2022), ensuring safe operation even in environments with high static electricity.

Additional Reliability Features

Panasonic has also addressed other thin-film vulnerabilities:

- Thermal Shock Resistance: Prevents solder cracks during temperature fluctuations

- Corrosion Resistance: Protects against flux penetration and sulfidation during soldering

These enhancements are made possible through careful selection of materials and innovative design, resulting in weather-resistant, long-life resistors suitable for demanding automotive environments.

Conclusion: Panasonic Resistors Drive EV Innovation

Panasonic’s thin-film chip resistors offer a unique combination of compact size, high reliability, and environmental resistance. Their adoption in EV systems contributes to:

- Reduced circuit board space

- Lower component costs

- Enhanced system reliability

- Improved battery health monitoring

- Safer and longer-lasting amplifier circuits

As EV technology continues to evolve, Panasonic remains committed to delivering high-performance components that meet the industry's most demanding requirements.