1. Introduction

Electrolytic capacitors remain a trusted choice for engineers due to their high ripple current capability, reliability, and cost-effectiveness.

However, as power electronics evolve—especially in automotive and industrial sectors—the demand for low ESR (Equivalent Series Resistance) has become critical for efficiency and stability.

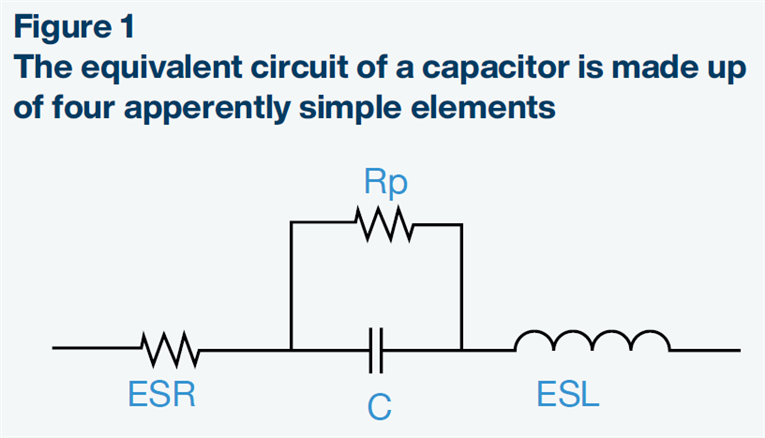

2. What is ESR and Why Does It Matter?

ESR represents the resistive component within a capacitor’s equivalent circuit. It influences:

- Power efficiency: High ESR increases losses and heat generation.

- Ripple voltage: Low ESR ensures cleaner, stable power for microprocessors.

- System reliability: Lower ESR extends capacitor life and improves control loop stability.

3. Advantages of Low ESR Capacitors

- Reduced ripple voltage for stable power delivery.

- Enhanced energy efficiency and compliance with global standards (ENERGY STAR, EU Code of Conduct).

- Longer operational life due to minimized internal heating.

4. Panasonic’s Low ESR Solutions

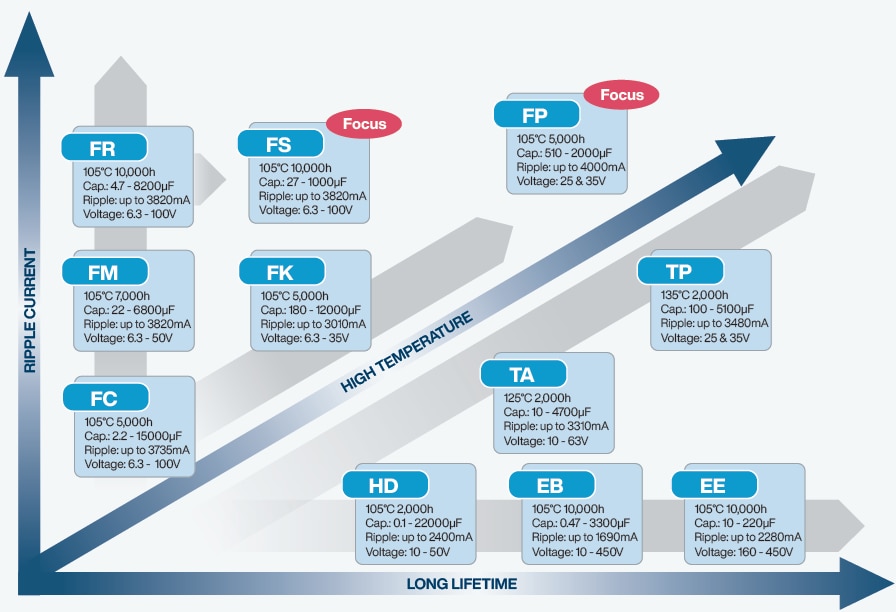

Panasonic offers one of the industry’s most comprehensive portfolios of low ESR electrolytic capacitors, available in THT (Through-Hole) and SMD (Surface-Mount) configurations.

4.1 THT Series Highlights

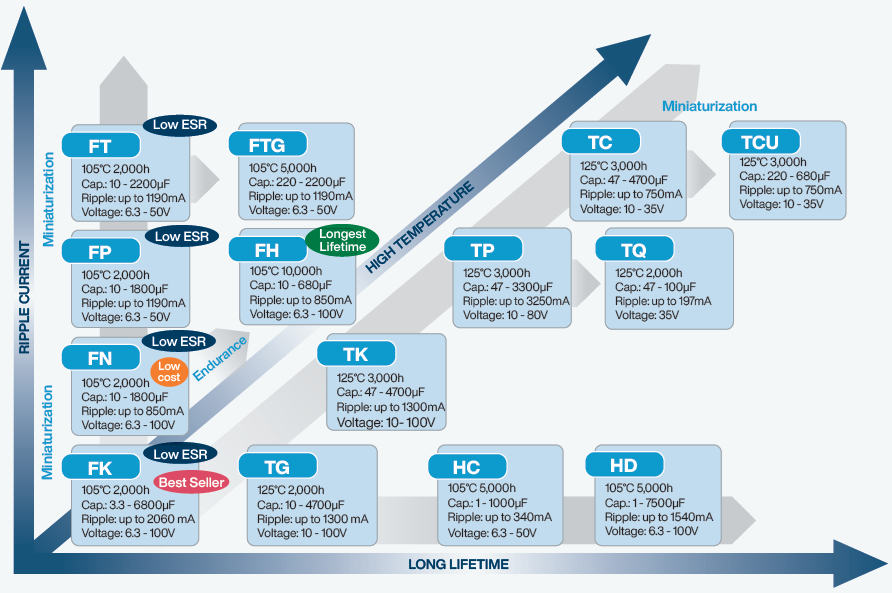

4.2 SMD Series Highlights

- FK Series: Broad offering for miniaturized designs, low ESR ideal for high-efficiency systems.

- FT Series/ FP Series: ESR values down to 60 mΩ in compact packages.

- TCU Series: Automotive-grade, AEC-Q200 qualified, vibration-proof options available.

5. Automotive and Industrial Applications

- Automotive ECUs: High ripple current handling for DC/DC converters.

- Industrial Power Supplies: Stable filtering under harsh conditions.

- Driverless Car Systems: High-temperature and vibration-proof designs for safety-critical electronics.

6. Why Choose Panasonic?

- Extensive product range for diverse applications.

- Proven reliability under real-world conditions.

- Compliance with AEC-Q200 and global efficiency standards.

Explore Panasonic’s full range of low ESR electrolytic capacitors on Element14