1. What Types of Cameras Are Used in ADAS and AD Systems?

Automotive cameras are essential sensing devices that help vehicles interpret their surroundings. In both Advanced Driver Assistance Systems (ADAS) and Autonomous Driving (AD), cameras work alongside radar, LiDAR, and ultrasonic sensors to build a multi‑directional understanding of the environment.

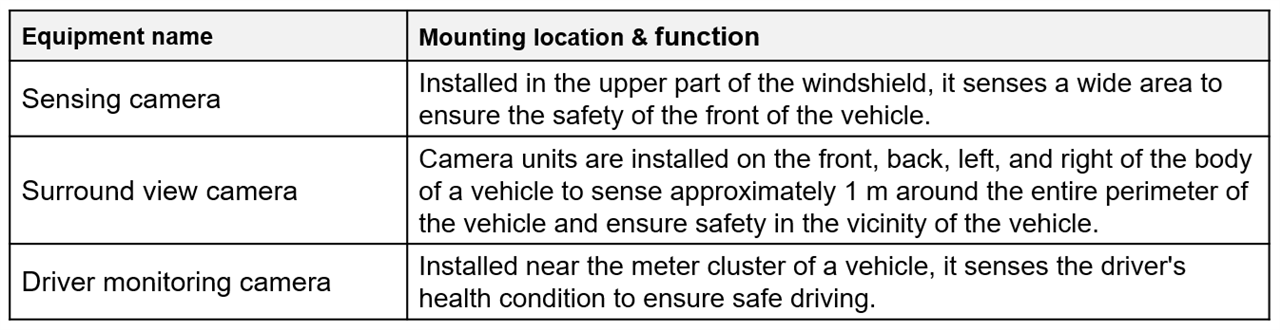

Modern vehicles typically integrate three primary camera categories:

• Sensing Cameras (Forward‑Facing)

Mounted near the top of the windshield, these cameras monitor a wide forward area to support key safety functions such as lane keeping, lane changing, traffic sign detection, and automatic emergency braking.

• Surround View Cameras

Installed at the front, rear, and both sides of the vehicle body, these cameras capture near‑range images to create a 360° view. They support parking assist and low‑speed maneuvering.

• Driver Monitoring Cameras

Positioned near the instrument cluster, these cameras track the driver’s condition, including eye closure, gaze direction, and signs of drowsiness or inattention.

Each camera type serves different operational goals, yet all contribute to safer, more automated driving experiences.

2. Uses and Functions of Each Camera Type

Different ADAS/AD features depend on specific camera modules. Below is an overview of their major applications:

Sensing Cameras

Used for decision‑making and control actions:

- Lane Keep Assist (LKA)

- Lane Change Assist (LCA)

- Autonomous Emergency Braking (AEB)

- Forward collision avoidance

- Traffic sign recognition

These cameras play a central role in higher‑level AD systems where precise object detection and classification are essential.

Surround View Cameras

Primarily used for:

- Parking assistance

- Close‑range obstacle detection

- Surround visualization in the cockpit display

These cameras help drivers—and autonomous systems—understand vehicle positioning in tight spaces.

Driver Monitoring Cameras (DMS)

Used for:

- Assessing the driver’s alertness

- Detecting fatigue or inattention

- Monitoring head pose and gaze direction

As global regulations evolve, DMS is becoming mandatory in many markets.

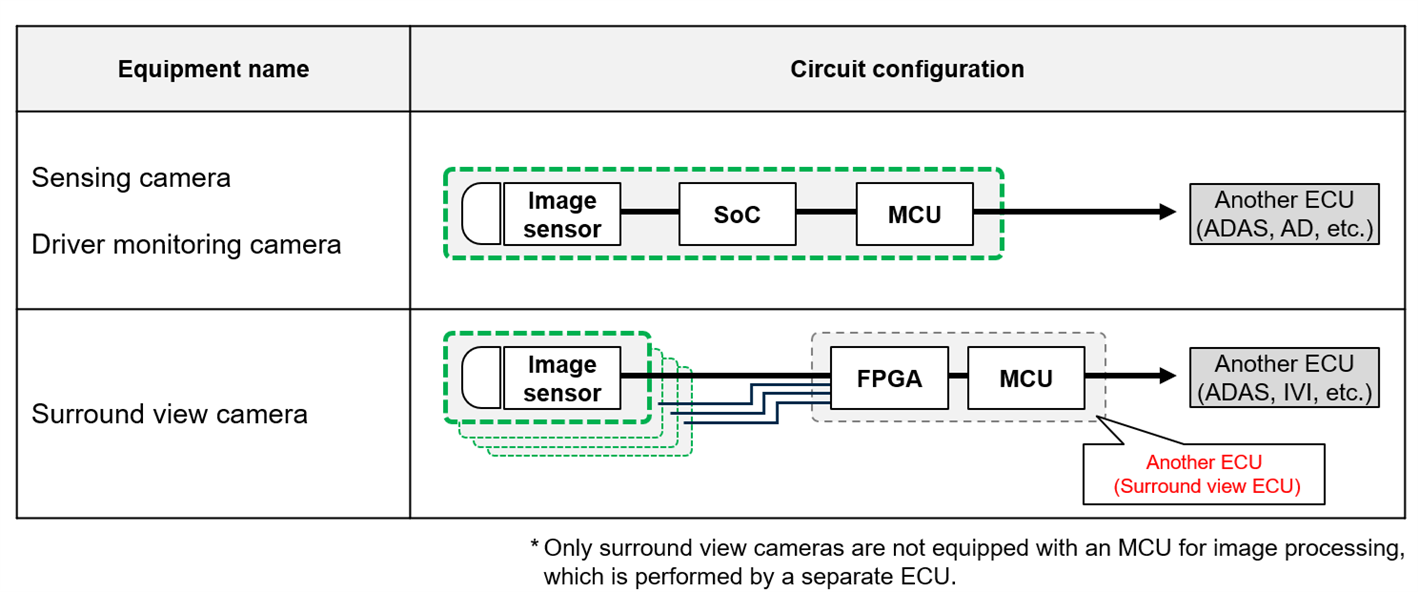

3. Internal Configuration of Automotive Cameras

Although sensing, surround view, and driver monitoring cameras differ in purpose, their internal architectures share common building blocks.

Sensing Cameras & Driver Monitoring Cameras

These modules typically include:

- Image Sensor – Converts incoming light into electrical signals.

- SoC (System-on-Chip) – Performs image analysis, object recognition, and high-speed processing.

- MCU – Issues control commands to external ECUs.

- Transceiver – Handles data communication with ADAS/AD ECUs.

- DDR Memory – Provides high‑speed data buffering.

- Flash Memory – Stores firmware and calibration data.

Surround View Cameras

This type uses multiple image sensors, each positioned around the vehicle.

Captured images are transferred to a Surround View ECU, where an FPGA or high‑performance SoC synthesizes them into a single omnidirectional view.

Captured images are transferred to a Surround View ECU, where an FPGA or high‑performance SoC synthesizes them into a single omnidirectional view.

Because of the volume of image data involved, communication bandwidth and processing speed are especially critical.

4. Market Trends and Camera Module Requirements

With increasing vehicle production and the rapid evolution of autonomous driving, camera units are expected to grow in both quantity and capability.

Future camera modules are increasingly driven by three major performance demands:

Future camera modules are increasingly driven by three major performance demands:

4.1 Higher Power Capability

- Rising image sensor resolutions

- Higher dynamic range performance

- More advanced SoCs requiring substantial computational power

These factors raise internal losses and thermal loads, demanding high‑current, low‑loss components.

4.2 Higher‑Speed Data Transmission

As image data volumes grow, communication interfaces require:

- High‑frequency performance

- Low‑parasitic components

- High‑speed EMI/ESD protection

Automotive Ethernet and other high‑rate protocols rely heavily on robust passive components.

4.3 Miniaturization and Weight Reduction

Compact camera modules reduce vehicle weight, simplify mounting, and enhance design flexibility.

Achieving this requires smaller yet more capable capacitors, inductors, and resistors.

Achieving this requires smaller yet more capable capacitors, inductors, and resistors.

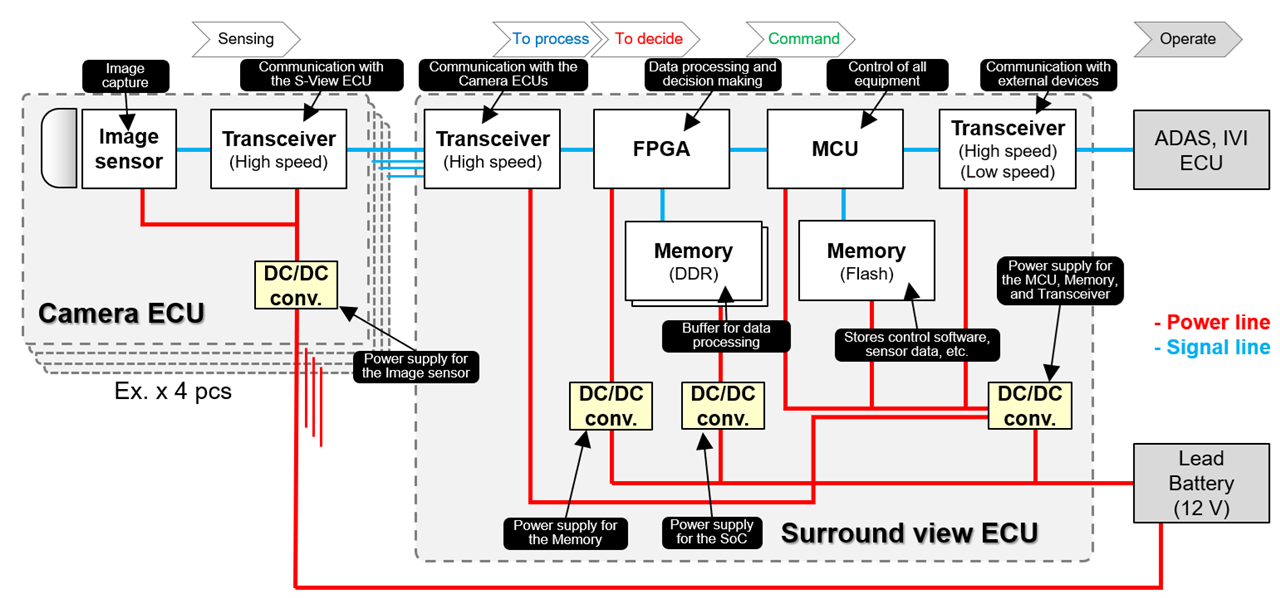

5. Circuit Configuration of Each Camera Module

The following components constitute the core circuitry of sensing and driver monitoring cameras:

• Image Sensor

Captures visual data and converts light into electrical signals.

• SoC

Processes images, performs recognition algorithms, and generates control outputs.

• MCU

Handles operational commands and coordinates with system‑level ECUs.

• Transceiver (High‑ and Low‑Speed)

Supports communication with other vehicle systems.

• DDR Memory

Acts as a buffer for real‑time image processing.

• Flash Memory

Stores firmware, system configuration, and calibration parameters.

• DC/DC Converters

Provide regulated voltages for image sensors, memory, SoCs, and communication ICs.

These power stages must address noise suppression, fast transient response, and minimal ripple to prevent image degradation.

Surround view camera

A camera ECU and surround view ECU are used to make up a surround view camera. Unlike other types of camera modules, multiple camera units are mounted on a vehicle to make up the surround view camera. Therefore, transceiver circuits must communicate larger amounts of data. An FPGA is used to integrate the acquired image data into one, where image processing is performed at high speed.

Other configurations are the same as those of sensing cameras and driver monitoring cameras.

6. Specific Component Examples and Their Applications

Both DC/DC converter circuits and transceiver interfaces rely heavily on high‑performance passive components. Panasonic’s automotive‑grade devices play key roles in achieving reliable and compact designs.

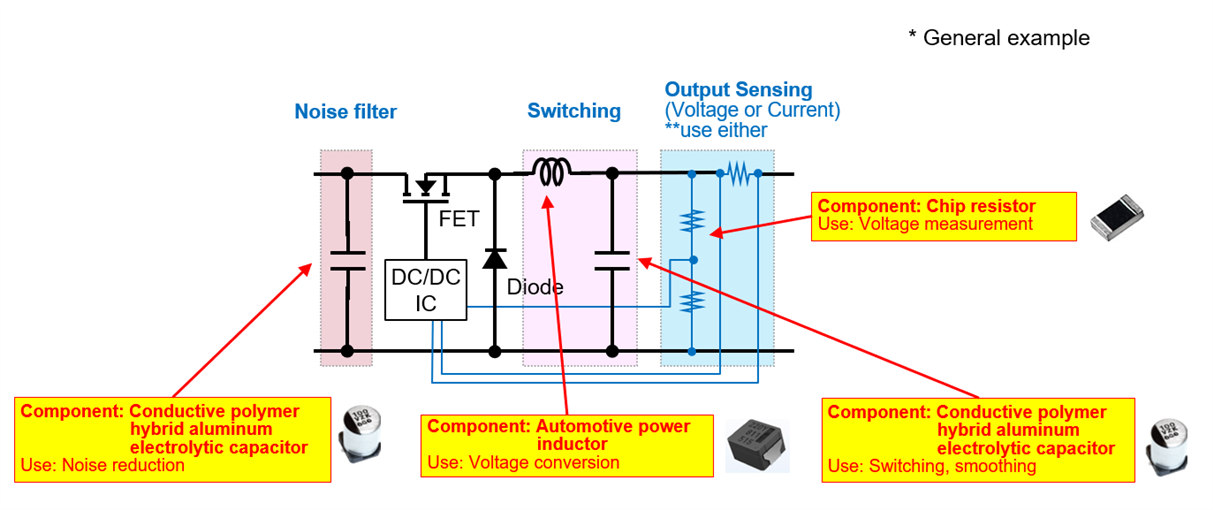

6.1 DC/DC Converter Components

DC/DC converters commonly integrate:

Conductive Polymer Hybrid Aluminum Electrolytic Capacitors

Ideal for:

- Noise reduction

- Smoothing output ripple

- High‑frequency filtering

Key benefits:

- High capacitance with low ESR

- Excellent ripple current handling

- Stable performance across wide frequencies

Automotive Power Inductors

Used for:

- Efficient voltage conversion

- High‑current power stages

Key benefits:

- Metal composite materials for low core loss

- Excellent current handling

- Reduced AC resistance at high switching frequencies

High‑Precision Chip Resistors

Used for:

- Voltage measurement and sensing

- Feedback control accuracy

Key benefits:

- Thin‑film structures with low temperature coefficients

- Accurate resistance values for stable regulation

Components used in a DC/DC converter

6.2 Transceiver Interface Components

Transceiver circuits often face ESD and EMI challenges because they interact directly with external communication lines.

Chip Varistors

Used for:

- ESD suppression

- Noise filtering on CAN, Ethernet, and LVDS lines

Key benefits:

- Wide capacitance range (suitable for various speeds)

- Effective noise absorption without harming signal quality

ESD Suppressors

Used for:

- Protecting high‑speed interfaces

- Ensuring signal integrity in fast communication links

Key benefits:

- Ultra‑low capacitance (~0.1 pF range)

- Ideal for high‑speed automotive Ethernet

Panasonic’s protective components provide robust safeguarding for critical transceiver ICs.

Components used in a transceiver IF

Components used in a transceiver IF

7. Panasonic Product Lineup and Key Advantages

As camera systems advance, automotive components must deliver:

- High current capability

- Low loss and reduced heat generation

- High‑frequency operation

- Compact size

- Long‑term reliability

- Precision measurement capability

Panasonic Industry provides a wide portfolio tailored to these demanding requirements:

• Conductive Polymer Hybrid Aluminum Electrolytic Capacitors

- Low ESR, high ripple durability

- Ideal for miniaturized high‑current designs

• Automotive Power Inductors

- Low loss at high frequencies

- Stable performance for compact power stages

• High‑Precision Chip Resistors

- Tight tolerance, high heat resistance

• Chip Varistors

- Wide capacitance options for CAN to Ethernet

• ESD Suppressors

- Ultra‑low capacitance for high‑speed digital lines

These components are readily available through Farnell, enabling engineers to design robust, next‑generation ADAS camera modules.