Table of Contents

- 1. Back to Basics: What is Electric Power Steering (EPS)?

- 2. The Evolution of Steering: Key Technological Shifts

- 3. The Non-Negotiable: Redundancy for Ultimate Safety

- 4. Anatomy of an EPS Circuit: An Overall Configuration

- 5. Component-Level Solutions for Optimal Performance

- Summary: Building the Future of Steering

The automotive industry is in the middle of a seismic shift. With the rise of autonomous driving and electrification (the "CASE" era), core vehicle systems are being completely re-imagined. One of the most critical evolutions is happening in the steering system.

As we move towards higher levels of vehicle autonomy, the demands placed on Electric Power Steering (EPS) systems are exploding. Engineers are now tasked with designing circuits that are not only more powerful and efficient but also meet unprecedented standards for safety and reliability. How do you design an EPS that can handle the complex demands of by-wire technology and functional safety while minimizing power loss and physical footprint?

This article provides a technical deep-dive into the modern EPS, breaking down its architecture, the technological forces shaping its evolution, and the critical electronic components that form its backbone.

1. Back to Basics: What is Electric Power Steering (EPS)?

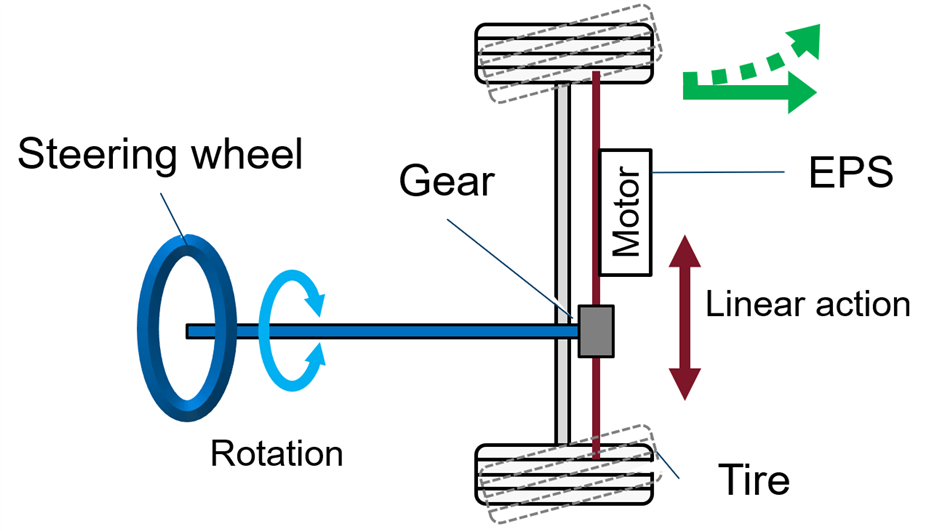

At its core, an Electric Power steering (EPS) is a system that uses an electric motor to assist the driver, reducing the effort needed to turn the steering wheel. Unlike traditional hydraulic systems that constantly draw power from the engine, an EPS is far more efficient, only consuming energy when steering assistance is required. This directly contributes to better fuel economy and is a key enabler for electric vehicles (EVs).

(Figure1: Operation of the EPS)

2. The Evolution of Steering: Key Technological Shifts

The EPS is evolving rapidly due to two major trends:

-

Electrification: Modern vehicles rely on battery power. Electrifying components like the steering system simplifies the overall mechanism and improves energy efficiency. For autonomous driving, where the vehicle's computer needs total control, full electrification is essential.

-

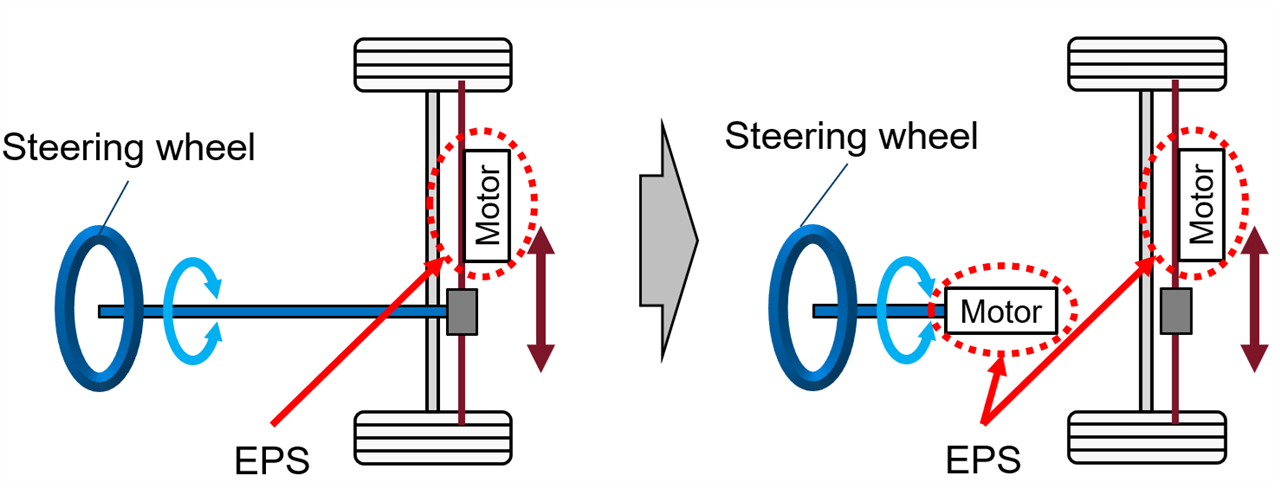

By-Wire Connection: The future of steering is "by-wire". This means the mechanical link between the steering wheel and the axle is replaced by an electrical connection. This separation allows for more precise, computer-controlled steering adjustments, a fundamental requirement for autonomous navigation. As the driver's role diminishes at higher autonomy levels, the vehicle assumes primary control, making by-wire systems indispensable.

(Figure:2 Configuration change resulting from by-wire connection)

3. The Non-Negotiable: Redundancy for Ultimate Safety

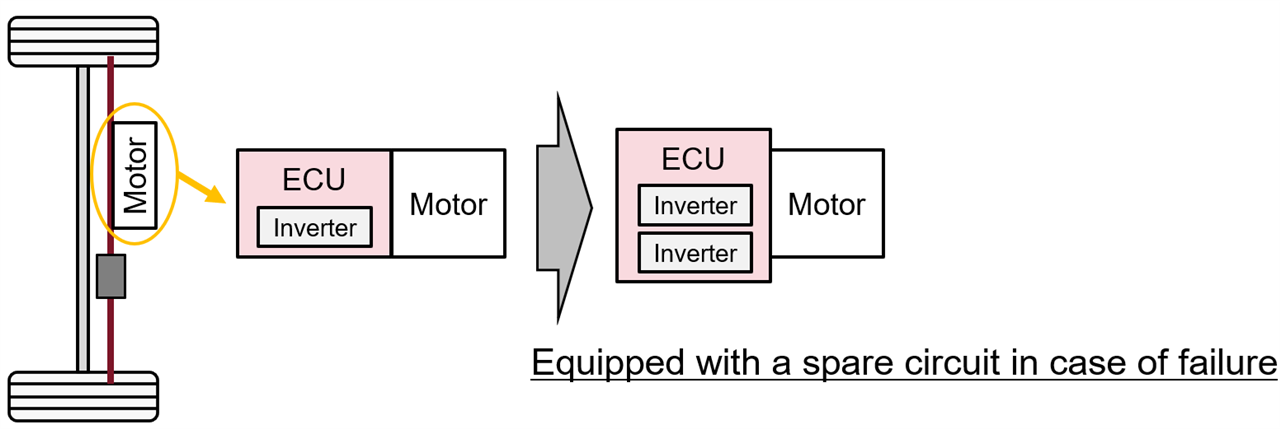

With greater autonomy comes greater responsibility. In a by-wire system, failure is not an option. To ensure maximum safety and reliability, modern EPS designs incorporate a redundant structure. This often means building the motor-driving inverter with a dual-circuit design. If one circuit fails, a backup immediately takes over, ensuring the system remains operational.

However, this raises a new engineering challenge: redundant circuits, along with the need for more powerful motors in advanced systems, increase power consumption. This dilemma forces engineers to seek out electronic components that deliver on four key properties: low loss, high heat resistance, high precision, and small size.

(Figure3: Configuration changes resulting from the adoption of a redundant structure)

4. Anatomy of an EPS Circuit: An Overall Configuration

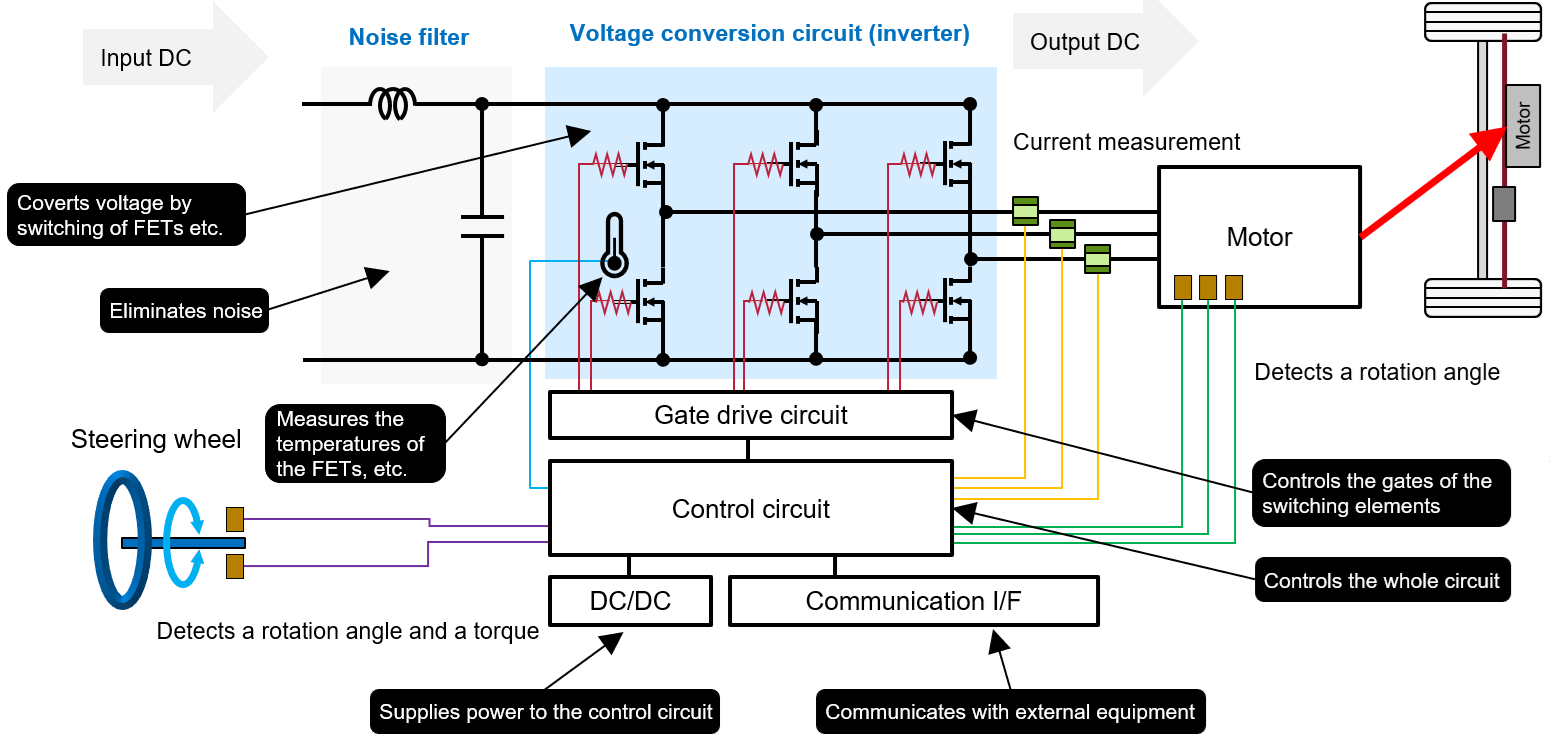

Let's break down the key functional blocks within a typical EPS electronic control unit (ECU):

-

Noise Filter: Suppresses electromagnetic interference (EMI), both internal and external, to prevent system malfunctions.

-

Voltage Conversion Circuit (Inverter): Converts the vehicle's DC voltage to power the motor, typically using Field-Effect Transistors (FETs) for high-frequency switching. It also monitors the temperature of these critical components.

-

Gate Drive Circuit: Precisely controls the switching of the FETs in the inverter.

-

DC/DC Converter: Steps down voltage to supply stable power to the main control circuit.

-

Control Circuit: The "brain" of the EPS, processing inputs (like torque and rotation angle from the steering wheel) and controlling the entire system.

-

Communication I/F: Manages data exchange with other vehicle systems via protocols like CAN or Ethernet.

5. Component-Level Solutions for Optimal Performance

The overall performance of the EPS system hinges on the quality of its individual components. Here’s a look at the critical parts used in each circuit block and how they solve key design challenges.

5-1. Noise Filter & Voltage Conversion

This circuit requires components that can handle large currents and suppress high-frequency noise generated by the inverter's switching.

-

Key Challenge: Balancing noise suppression, high power capacity, and a compact footprint.

-

Component Solution:

-

Conductive Polymer Hybrid Aluminum Electrolytic Capacitors: These offer the best of both worlds: high capacitance and low ESR (Equivalent Series Resistance). This allows them to effectively smooth voltage and suppress ripple current in a smaller package, handling the high-current demands of the motor.

-

Power Inductors for Automotive Application: Built with metal magnetic materials, these inductors feature low power loss (low ACR at high frequencies) and support large currents. This contributes directly to higher efficiency and a smaller overall circuit size.

-

> Explore Panasonic's high-performance Capacitors and Power Inductors designed for demanding automotive applications.

5-2. Voltage Conversion and Temperature Sensing

The high-power switching elements (FETs) in the inverter generate significant heat. Managing this heat and suppressing switching noise is critical to prevent component failure.

-

Key Challenge: Precise temperature measurement and noise suppression in a high-power environment.

-

Component Solution:

-

Small, High-Power Chip Resistors: Used on the gate terminals of FETs to suppress driving noise. Advanced resistor patterns and electrode structures allow these components to handle high power in a very small footprint.

-

NTC Thermistors (Chip-type): These small, highly heat-resistant thermistors are placed near the FETs to provide precise, real-time temperature feedback to the control circuit, enabling proactive thermal management.

-

> Discover Panasonic's High-Power Chip Resistors and high-reliability NTC thermistors.

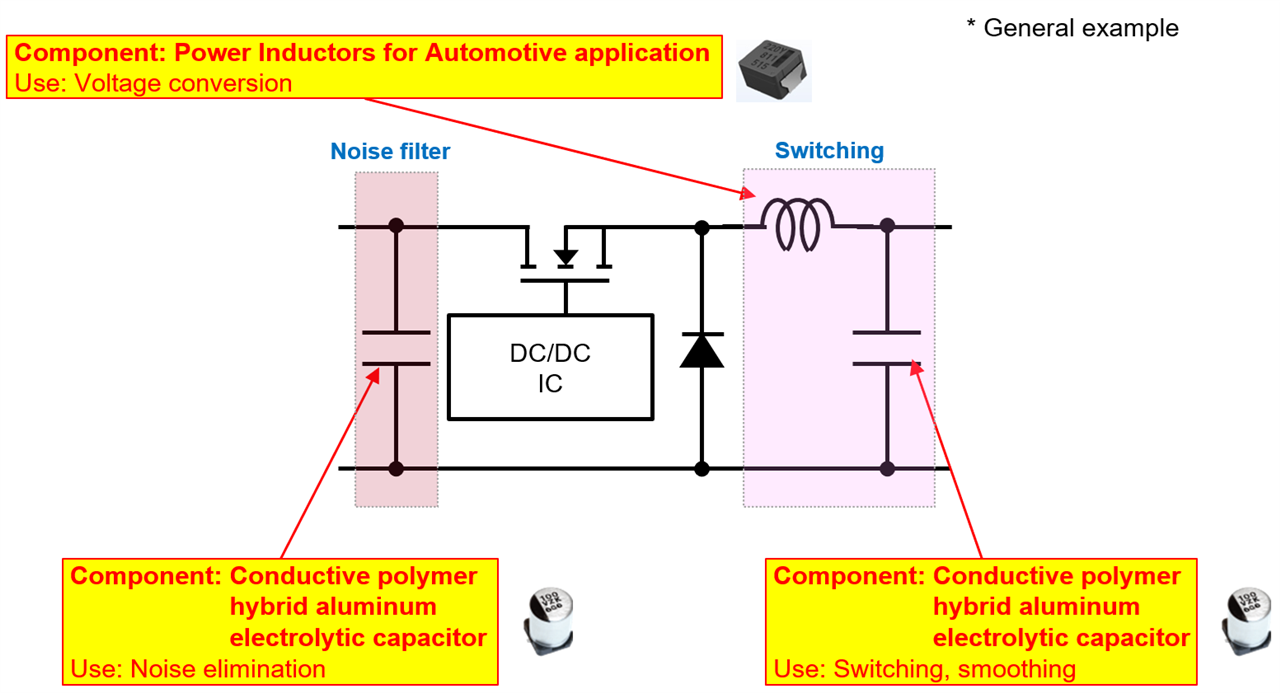

5-3. DC/DC Converter

This circuit is essential for providing stable power to the microcontroller. It requires robust filtering and efficient voltage conversion.

-

Key Challenge: Ensuring clean, stable power for sensitive control electronics.

-

Component Solution: The same high-performance Conductive Polymer Hybrid Aluminum Electrolytic Capacitors and Power Inductors used for noise elimination and smoothing at the input and output stages.

(Figure5: Components used in the DC/DC converter)

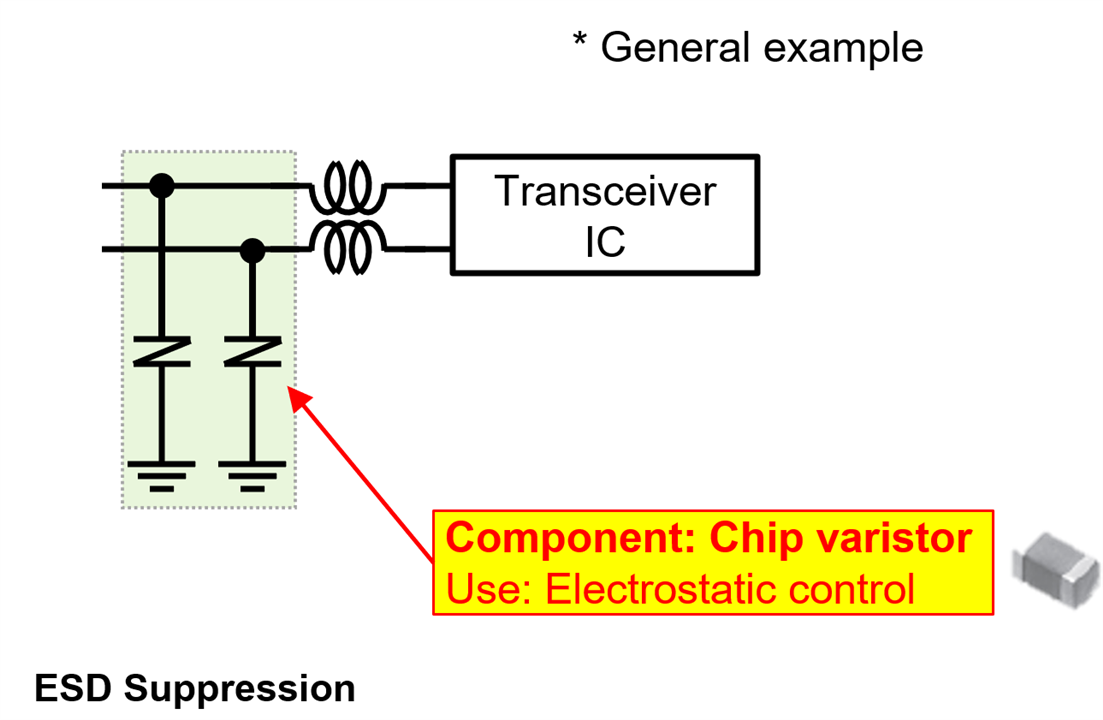

5-4. Communication Interface

Communication lines (like CAN bus) are susceptible to electrostatic discharge (ESD) and other noise that can damage the transceiver IC.

-

Key Challenge: Protecting sensitive communication circuits from ESD events without degrading signal quality.

-

Component Solution:

-

Chip Varistors: These components are designed to suppress ESD noise across a wide range of communication speeds. With capacitance values from 8 pF to 250 pF, they provide effective protection while preserving the integrity of the data signal.

-

> Protect your communication interfaces with Panasonic's automotive-grade Chip Varistors.

(Figure6: Components used in the communication I/F)

Summary: Building the Future of Steering

As the automotive industry accelerates towards a future defined by the "CASE" framework, the Electric Power Steering system is evolving from a simple driver-assist feature into a core component of vehicle automation and safety.

This evolution demands a move towards by-wire systems and redundant circuit architectures. To meet this technological leap, engineers must select electronic components that deliver low loss, high heat resistance, high precision, and a compact size.

Panasonic Industry offers a comprehensive portfolio of automotive-grade components designed to meet these stringent requirements, empowering engineers to build the safe, reliable, and efficient EPS systems of tomorrow.

|

Component |

Feature |

Low loss |

Small size |

High resistance to heat |

|

Low ESR High reliability |

|

|

|

|

|

Large current, low loss High reliability |

|

|

|

|

|

High precision, high resistance to heat |

|

|

||

|

Small and light |

|