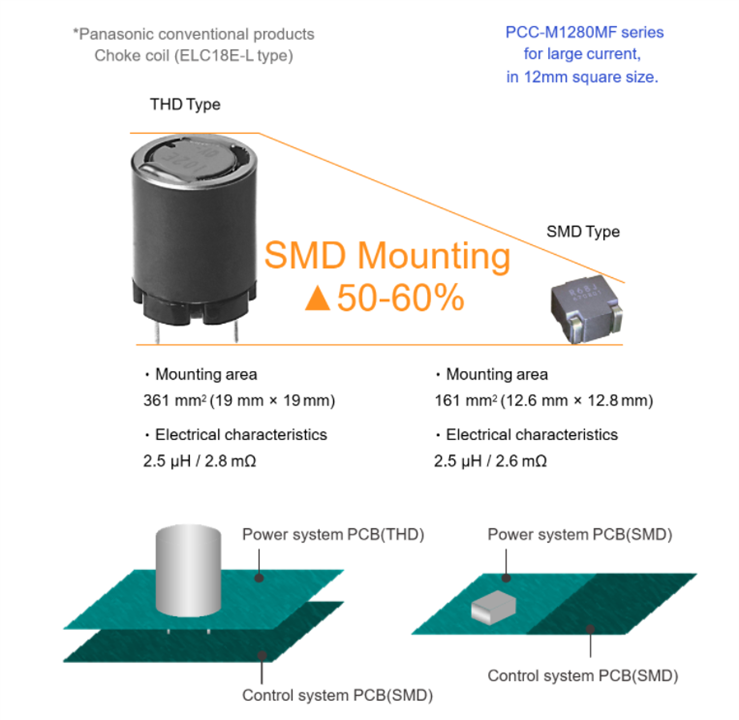

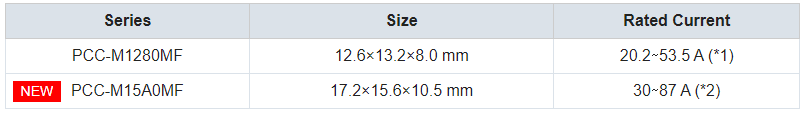

The increasing requirement of performance of automotive devices leads to higher electric current flowing trough electric circuits. Also the number of ECUs mounted on vehicles is gradually increasing. As space inside vehicles is limited, ECU boards must be downsized. Therefore it is essential for electronic components mounted on such boards that they are able to pass large currents and also meet downsizing requirements. Unfortunately large current type inductors are usually designed with through hole mounting type with large product sizes, which are not suitable for downsizing. Furthermore, a large range of passive components such as resistors and capacitors are surface-mounted, but this process cannot be simultaneously performed with through hole mounting. Therefore two board mounting processes are required. To solve this issue for automotive customers, Panasonic developed a power inductor which can be surface mounted and is capable of passing currents as large as 87A.

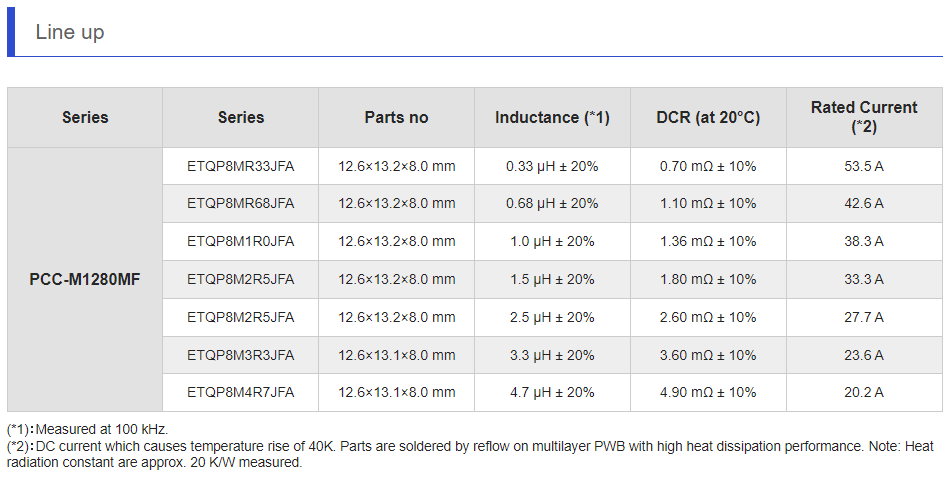

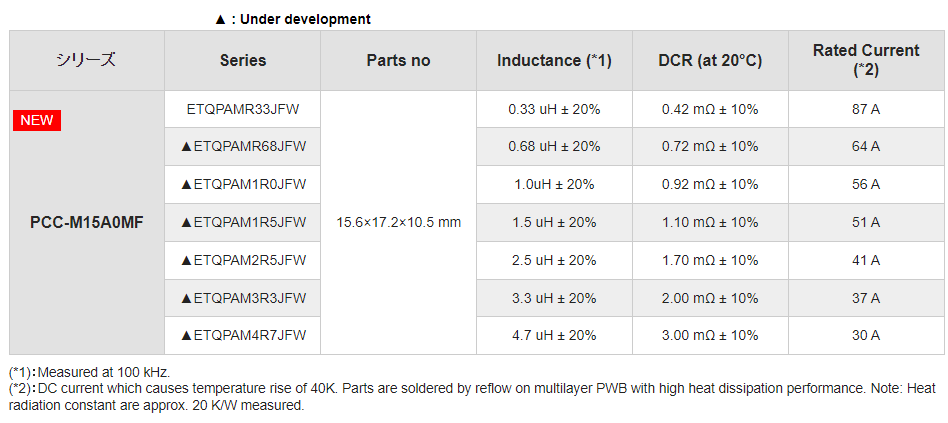

3 Features of ETQP8M***J** & ETQPAM***JFW series:

- Industry’s smallest class of surface-mounted inductor capable of passing large currents

- The inductor enables ECUs to be directly mounted on engines by achieving excellent heat and vibration resistance.

- The environmental impact can be reduced through installation space saving

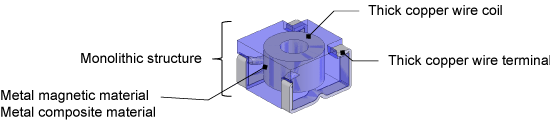

In contrast to conventional ferrite inductors, the magnetic metal composite material and the wired coil enable a gapless monolithic structure of the ETQP series. The result is a power inductor which has much lower heat generation due to reduced coil heat generation and increased coil heat dissipation. This way it was possible to enable large currents of 20A to 87A at a volume reduction of up to 50% compared to the ferrite type.

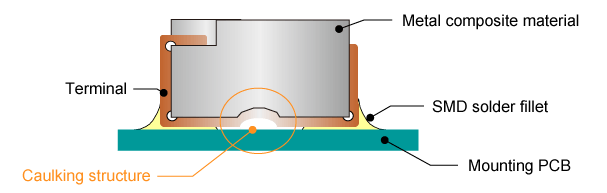

Heat resistance of 160°C is achieved by working on the composition of metal composite material. In addition, while the thick copper wire of the coil is drawn out to be used as terminals, an unique structure is adopted by fixing the terminals on the metal composite material body in a caulking structure on the bottom side, thus the vibration resistance is enhanced.

By adopting a metal composite suitable for downsizing, the company achieved a smaller inductor size with a similar performance for ferrite type inductors, which makes it possible to reducing the installation area, reduce the size of equipment, and reduce the number of materials used. It is possible to reduce the environmental load.

Unique terminal structure technology to assure heat capacity as SMD type, with the copper wire of the coil drawn out to be used as terminals.

Fore more information, visit: Automotive power inductors | Panasonic Industry Europe GmbH