1. What Is LiDAR?

LiDAR (Light Detection and Ranging) is a sensing technology that measures the distance to objects by emitting laser pulses and capturing the reflected light. The combination of emission direction and time‑of‑flight enables the generation of a high‑resolution 3D point cloud, which is widely used in ADAS and autonomous driving systems. As vehicle automation advances, the adoption of LiDAR is expected to grow steadily.

| Optical element | Optical axis varying method | Type | Scanning |

|---|---|---|---|

| LD, PD | Mechanical method | Rotation by a motor | A number of LDs and PDs are rotated by a motor to scan the whole area. |

| Polygon mirror | Respective optical axes of a single LD and a single PD are varied by a polygon mirror in scanning. | ||

| Non-mechanical method (solid-state) | MEMS mirror | Respective optical axes of a single LD and a single PD are varied by a MEMS mirror in scanning. | |

| Phased array | Respective optical axes of a single LD and a single PD are varied by a waveguide in scanning. | ||

| Flash | Light from a light source, such as an LED, is emitted over a wide area, and reflected light is collectively scanned by an array of PDs. |

2. How LiDAR Measures Distance and Recognizes Objects

Distance Measurement

- A laser diode emits a pulse toward an object.

- A photodiode receives the reflected light.

- The distance is determined from the time between emission and reception.

Object Recognition

By repeatedly scanning in multiple directions, LiDAR creates a point cloud.

This data is used to:

- Identify obstacles

- Build dynamic 3D maps

- Estimate and correct the vehicle’s position in real time

3. Market Trends and Technical Requirements

As autonomous driving levels increase, LiDAR systems must meet three key requirements:

| Requirement | Reason |

|---|---|

| Higher power | Higher‑resolution sensing increases CPU load and power demands. |

| Faster communication | High‑frequency and high‑speed data transfer is essential to process large point clouds. |

| Smaller size & lighter weight | Vehicles incorporate more sensors, requiring miniaturized components. |

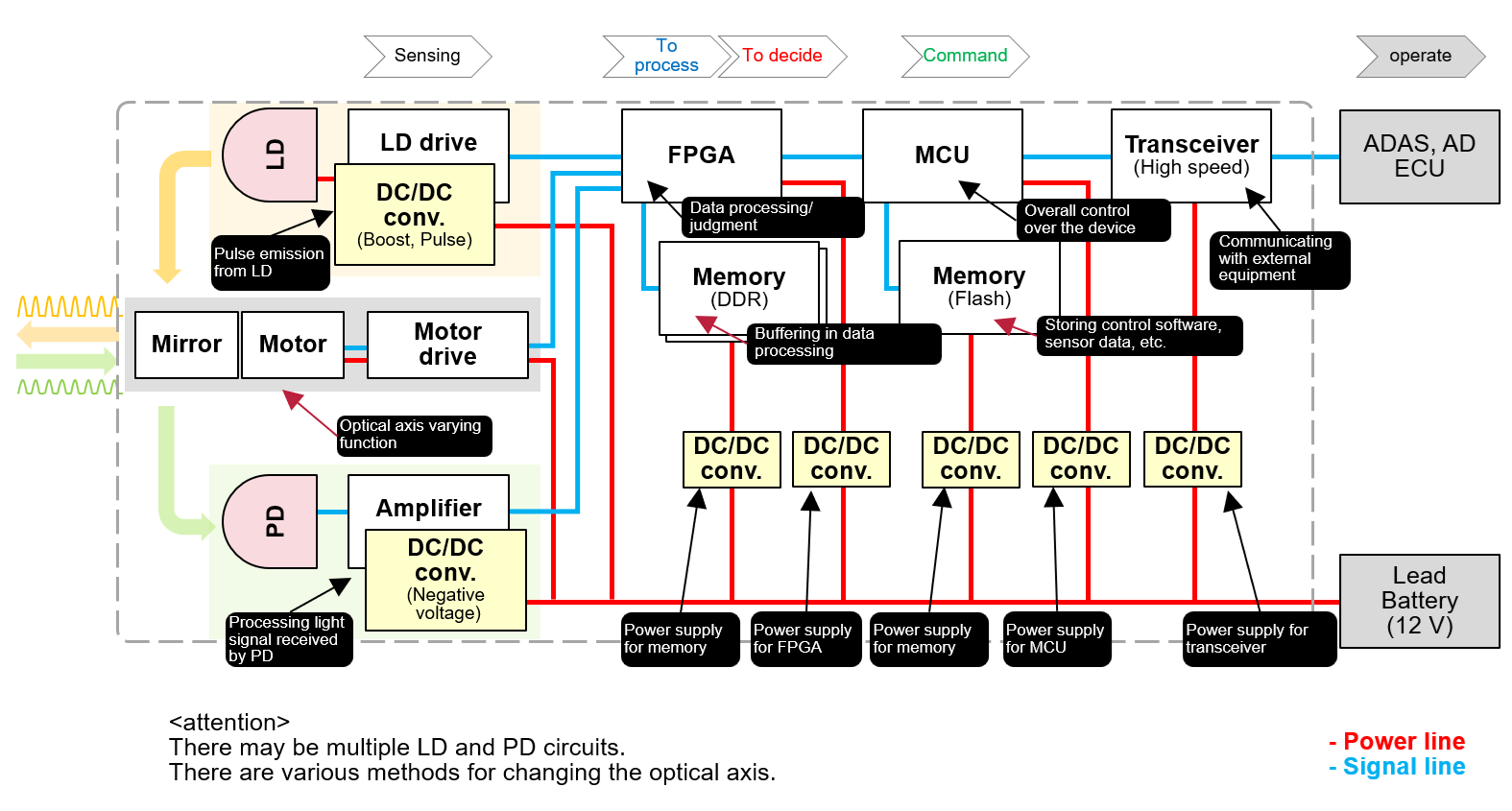

4. LiDAR System Overview

A LiDAR unit typically consists of:

- Laser Diode (LD): Emits high‑speed laser pulses

- Photodiode (PD): Converts received light into electrical signals

- Amplifier for the PD output

- FPGA: Handles high‑speed data processing

- MCU: Controls system operation

- Transceiver: CAN/Ethernet communication

- DDR & Flash Memory

- DC/DC Converters: Provide necessary voltage rails

5. Key Circuits and Recommended Components

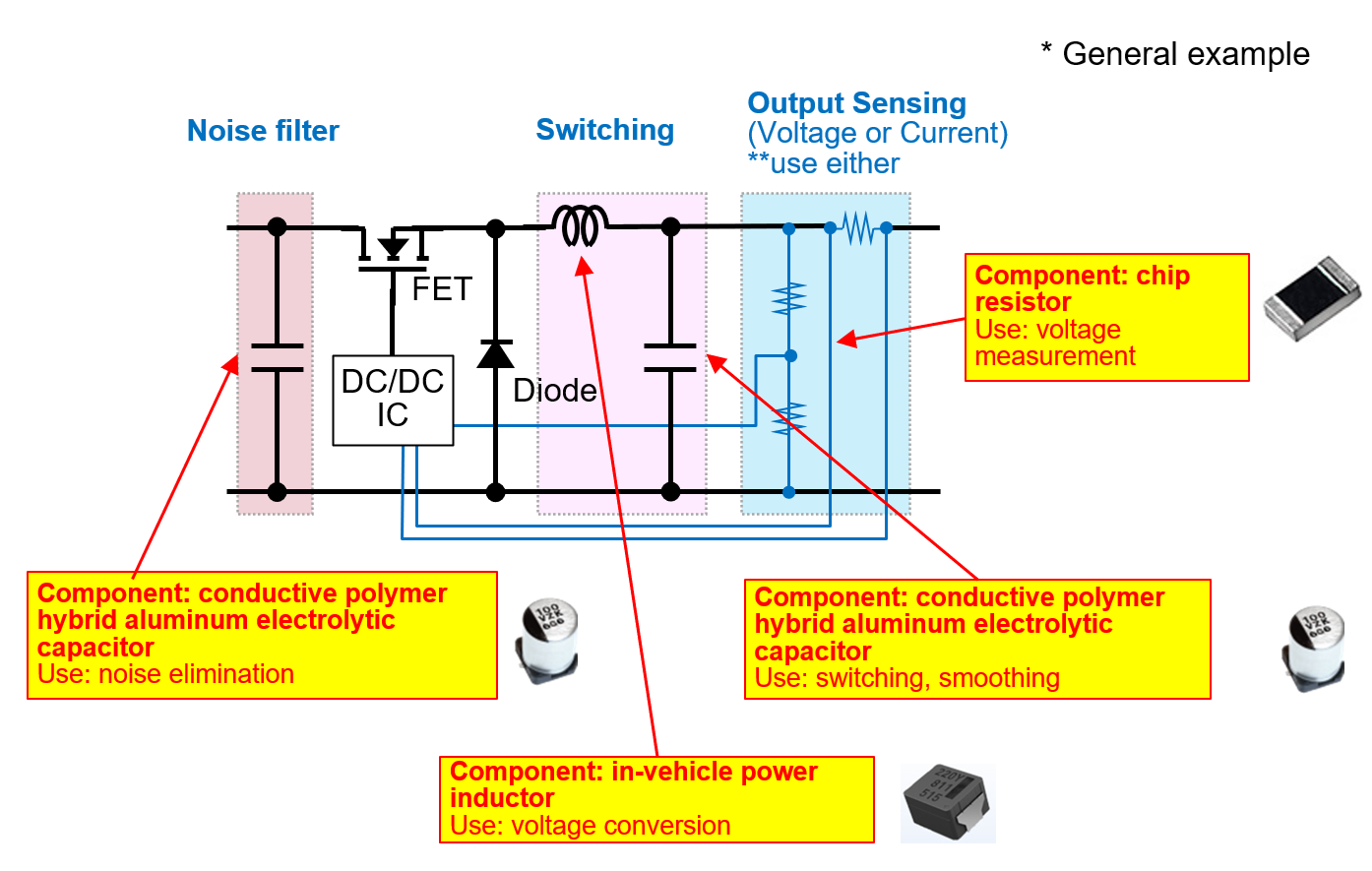

5‑1. DC/DC Converter Circuit

High‑performance LiDAR requires stable, low‑noise power.

Recommended Components

| Function | Component | Key Features |

|---|---|---|

| Noise filtering & smoothing | Conductive polymer hybrid aluminum electrolytic capacitor | Low ESR, high ripple tolerance, excellent high‑frequency behavior |

| Voltage conversion | Automotive power inductor | High current capability, low loss, low ACR |

| Voltage measurement | High‑precision chip resistor | Low resistance tolerance, low TCR for accurate control |

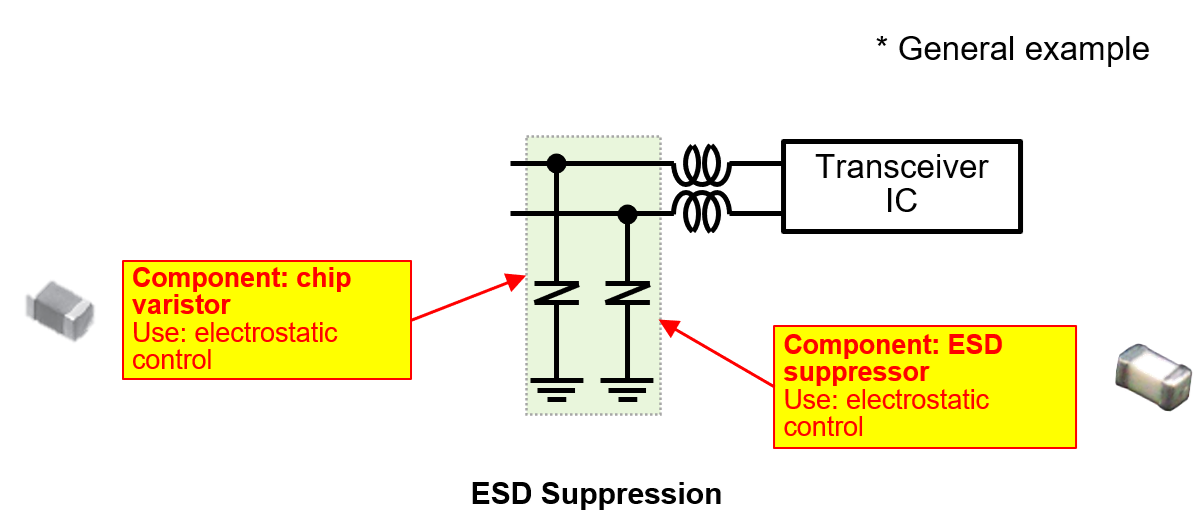

5‑2. Transceiver Interface (CAN / Ethernet)

Because communication lines are exposed to ESD, protection devices are critical.

Recommended Components

Key points:

- Chip varistors cover a wide capacitance range (8–250 pF) for low → high‑speed communication

- ESD suppressors (0.1 pF) are optimal for high‑speed interfaces

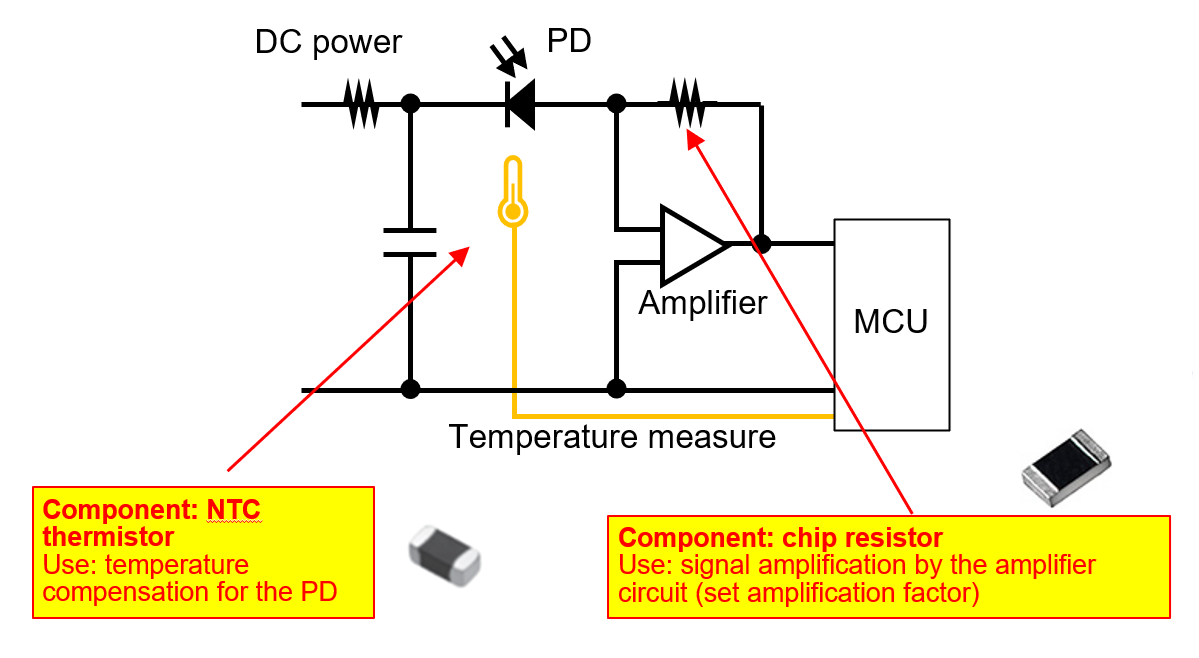

5‑3. Photodiode Light‑Receiving Circuit

Reflected laser light is weak and must be amplified with high precision.

Recommended Components

- High‑precision chip resistor → Sets amplifier gain

- NTC thermistor → Temperature compensation

Why they matter:

- Low‑TCR thin‑film resistors ensure stable gain

- High‑reliability thermistors maintain accurate sensing across temperatures

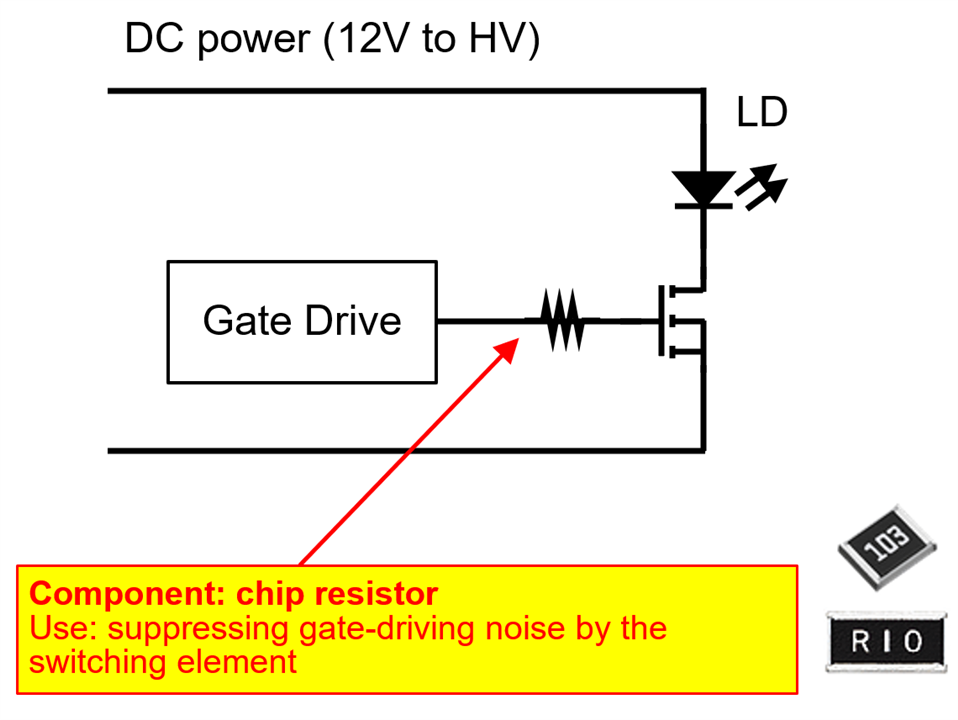

5‑4. Laser Diode Irradiation Circuit

A GaN FET is typically used to deliver high‑speed, high‑power pulses.

Recommended Components

Key advantage:

- Original resistance pattern and electrode design support high‑power switching while enabling device miniaturization

6. Conclusion

As autonomous vehicles adopt more LiDAR units, the demand for electronic components offering:

- Low loss

- High current capability

- High‑frequency performance

- Compact size & high reliability

will continue to grow. Panasonic Industry offers a broad portfolio—including hybrid capacitors, automotive inductors, high‑precision resistors, varistors, ESD suppressors, and thermistors—that aligns well with these requirements.

| Component | Feature | Large current | Low loss | High frequency | Small size | High precision |

|---|---|---|---|---|---|---|

| Conductive polymer hybrid aluminum electrolytic capacitor | Low ESR High reliability |

|||||

| Automotive power inductor | Large current, low loss High reliability |

|||||

| High precision, high resistance to heat | ||||||

| Chip varistor | Small and light | |||||

| ESD suppressor | Low capacitance Ultrafast data I/F |

|||||

| NTC thermistor (chip type) | Small, high resistance to heat |