MLCC problems - and their solution

MLCCs (Multi-layered Ceramic Capacitors) are used in a wide variety of applications but have problems due to inherent characteristics of MLCCs. Some of these problems can be solved by adopting conductive polymer capacitors. In the following, we will show you examples of two solutions.

First problem: The capacitances of MLCCs drop when they are supplied with DC biases or operated under high-temperature and/or low-temperature conditions. This leads to an increase in the number of MLCCs used.

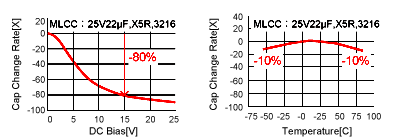

It is a well-known fact that the capacitances of MLCCs drop significantly when DC biases are applied to MLCCs and that the capacitances also drops when the MLCCs operate in high-temperature or low-temperature conditions.

The MLCC shown here in the graphs loses its capacitance by 80% when supplied with a 15 V DC bias voltage, and by about 10% when operating in high-temperature or low-temperature conditions.

Let's assume a case where MLCCs need to have a total capacitance of about 47 µF when supplied with a 15 V DC bias voltage. Taking the above capacitance reduction into consideration, we have to ensure the total capacitance based on the MLCC's nominal capacitance value of 20%. For the case of 22 µF MLCCs indicated in the graphs, the number of MLCCs to be used is calculated as follows.

22 µF × 20% = 4.4 µF 47 µF ÷ 4.4 µF ≅ 10.7

In this example, ensuring the total capacitance the circuit needs, which is 47 µF, requires 10 or more MLCCs each having the nominal capacitance of 22 µF, meaning that the total nominal capacitance amounts to 220 µF or more. The number of MLCCs used can be reduced by adopting a MLCC with a larger capacitance. However, the capacitance of a general chip-type MLCC with a 25 V voltage rating, a 47 µF (maximum) could be used, but it cannot be bigger than that. Therefore, when a larger capacitance is required, several MLCCs with a lower price and smaller capacitance are usually used as a general solution.

Solution: Replacing MLCCs with conductive polymer capacitors whose capacitances hardly fluctuate in response to DC biases or temperature conditions

Basically, different from an MLCC, a conductive polymer capacitor hardly shows a capacitance drop caused by DC biases or temperature conditions. Thus, the ten 22 µF MLCCs, in this example, can be replaced with one 47 µF conductive polymer capacitor. This reduction in the number of capacitors used leads to a reduction in total cost, including packaging-related costs. It is also possible we could even reduce the mounting area.

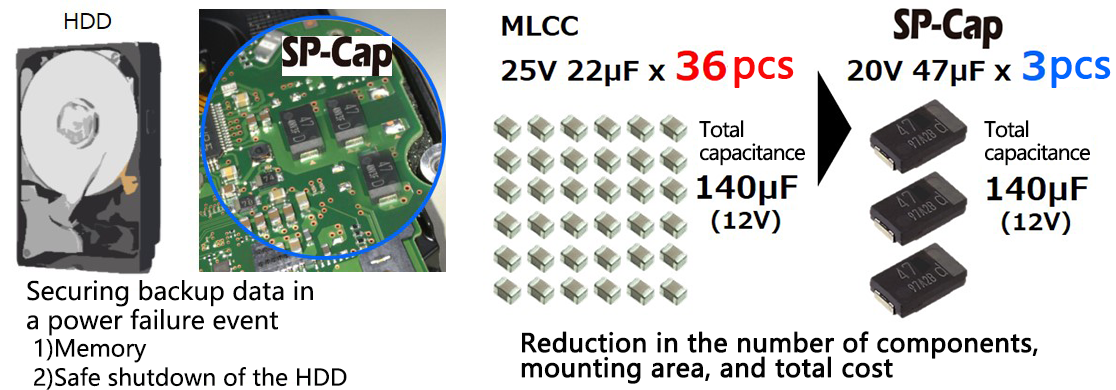

Here is a specific case of an HDD where a capacitance of about 140 µF is needed for a 12 V bias voltage in order to ensure data backup and safe shutdown of the HDD in a power failure event. To achieve the 140 µF capacitance using 22 µF MLCCs, we need 36 MLCCs, which brings the total nominal capacitance up to 792 µF based on the assumption that each MLCC has its capacitance reduced by about 80% due to DC biases. If we employ conductive polymer capacitors SP-Cap, however, three of them provide 47 µF × 3 = 141 µF, which meets the capacitance requirement. This case reduces the number of capacitors used and the mounting area as well, leading to a reduction in total cost. In addition to the SP-Cap, other conductive polymer capacitors, such as POSCAP, offer the same effect through the approach described above.

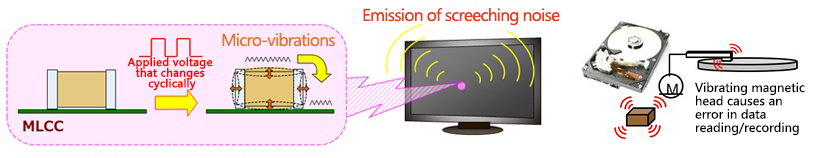

Second problem: Screeching noise emission and micro-vibrations

A MLCC deforms (contracts/expands) when a voltage is applied thereupon. This MLCC's characteristic is called inverse piezoelectric effect, which is the reverse of a piezoelectric effect. Applying a DC voltage to the MLCC merely causes it to deform. If the applied voltage has a frequency-controlled amplitude, however, the MLCC contracts and expands cyclically, thus causing the substrate to vibrate. If the frequency of such vibrations is within the audible frequency range, the resulting sound is unpleasant screeching noise. A DC voltage output from an AC adaptor or switching power supply causes a ripple voltage in some cases. If the frequency of the ripple voltage is within the audible frequency range, it may result in emission of a screeching noise.

There is also a case where micro-vibrations, if not creating noise, affect the operation of equipment. We have a case where the micro-vibration of a MLCC mounted on the magnetic head of an HDD causes an error in data reading/recording.

Solution: Replacing a MLCC with a conductive polymer capacitor that exhibits no inverse piezoelectric effect

There are MLCCs (improved MLCCs) configured for suppressing noise emission, which include a MLCC made of a material that hardly deforms, a MLCC with a length-width reverse structure in which its length, i.e., the distance between its electrodes is made shorter than its width, and an MLCC with leads, which are referred to as metal terminals or metal frames. It is true that such MLCCs certainly reduce noise emission and micro-vibrations but do not eliminate them completely.

A conductive polymer capacitor has no inverse piezoelectric effect and therefore causes no noise emission or micro-vibrations. Shown below is an example in which an MLCC, an improved MLCC with metal terminals, and a conductive polymer capacitor are compared regarding noise emission with each other.

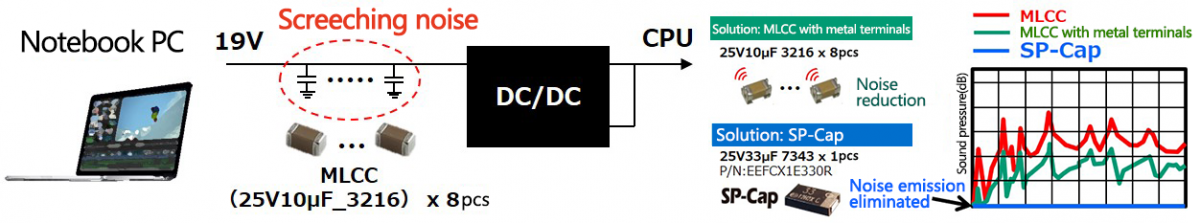

Here is an example in which a notebook PC' MLCCs (used as input capacitors in a DC/DC step-down converter for adjusting a voltage from the AC adaptor) cause screeching sound emission. MLCCs with metal terminals are said to be relatively effective as an alternative to ordinary MLCCs. The graph shown here demonstrates that MLCCs with metal terminals reduce the sound pressure of screeching noise. In the graph, a red curve represents ordinary MLCCs while a green curve represents MLCCs with metal terminals.

In this example, we have replaced eight 10 µF MLCCs with metal terminals with one 33 µF SP-Cap conductive polymer capacitor and checked noise emission. Obviously, the SP-Cap caused neither noise emission nor micro-vibrations, providing a perfect solution to the noise emission problem. This is the same outcome as adopting a SP-Cap in the previous case. Using other types of conductive polymer capacitors offers the same effect as described here.

Panasonic conductive polymer capacitors

A conductive polymer capacitor has an electrolyte made of conductive polymers, offering low equivalent series resistance (ESR), an excellent high-frequency property, and stable characteristics not dependent on temperature or voltage. Panasonic provides a lineup of various conductive polymer capacitors, putting four types of them on the capacitor market.

| Name/shape |  Aluminum polymer (laminated) |

Tantalum polymer |

Aluminum polymer (winding) |

Aluminum hybrid |

|---|---|---|---|---|

| Major features |

|

|

|

|

Product range

|

|

|

|

|

Conclusion

We have shown two examples concerning problems with MLCCs, which originate from their inherent characteristics, and solutions to the problems, which are provided by conductive polymer capacitors.

In one example, the capacitance drop of MLCCs caused by DC biases and temperature conditions is taken into consideration, which determines the number of MLCCs used so that the required total capacitance is achieved. Because the capacitance of each MLCC is not sufficient, a large number of MLCCs, having a relatively small capacitance, must be provided to achieve the total capacitance. In contrast, conductive polymer capacitors only exhibit minute capacitance fluctuations caused by DC biases and temperature conditions, and some of them have large capacitances. For this reason, replacing MLCCs with conductive polymer capacitors allows a reduction in the number of capacitors used and in the mounting area, thus leading to a total cost reduction.

In another example, we described the solution to noise emission and micro-vibrations that are caused by the inverse piezoelectric effect of MLCCs. While some improved MLCCs suppress noise emission and micro-vibrations to some extent, conductive polymer capacitors, which have no inverse piezoelectric effect, eliminate noise and micro-vibrations completely. Replacing MLCCs with conductive polymer capacitors, therefore, is a perfect solution to the noise emission/micro-vibration problem.

In these examples, a SP-Cap conductive polymer capacitor is described as the typical alternative to an MLCC. Depending on given requirements, conditions, etc., you can choose your optimum alternative from four types of conductive polymer capacitors: SP-Cap, POSCAP, OS-CON, and Hybrid.

Panasonic has web sites that provide detailed data of conductive polymer capacitors and other electronic devices.

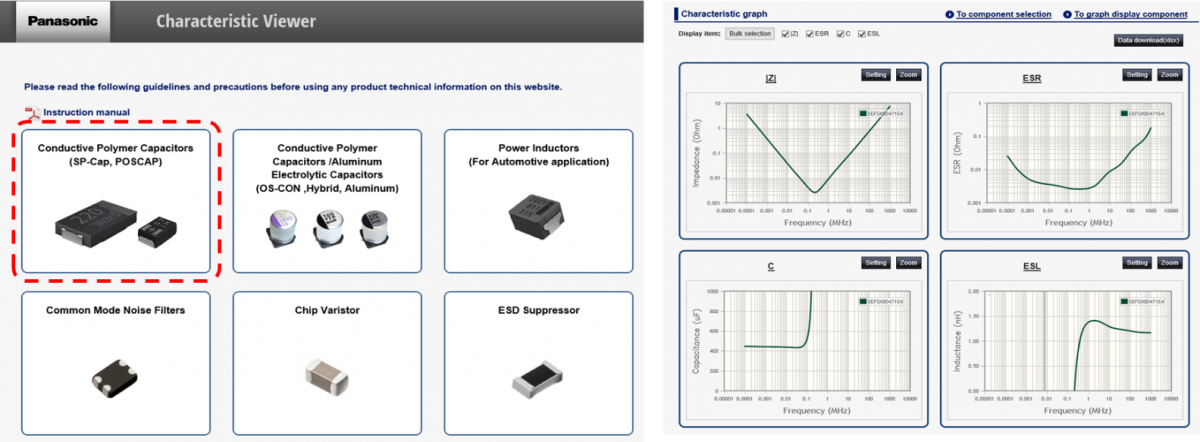

■Characteristic viewer

(https://util01.industrial.panasonic.com/ww/utilities/ds/chr-vw/)

The characteristic viewer is a tool with which various characteristics of a selected component are plotted on graphs having a frequency axis, temperature axis, etc. It allows you to easily check component characteristics, such as changes in characteristic values in the working frequency range, and is therefore useful as a component selection tool.

In the case of checking the characteristics of conductive polymer capacitors SP-Cap and POSCAP, using the characteristic viewer, the viewer indicates the frequency characteristics of the impedance |Z|, resistance component ESR, capacitance C, and inductance component ESL of SP-Cap and POSCAP.

Example: EEFSX0D471E4 (SX系列, 2V 470μF, ESR4.5mΩ)

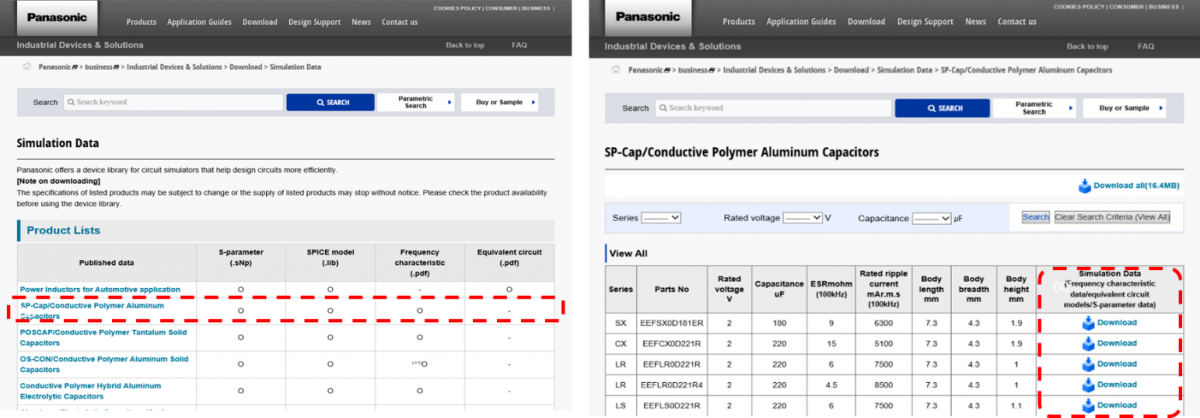

■Simulation Data

(https://industrial.panasonic.com/ww/downloads/simulation-data)

We also offer a web site for downloading simulation data. From this site, you can download frequency characteristic data (PDF), equivalent circuit models (SPICE models), and S parameters for each product number.

Example:EEFSX0D471**(SX系列、2V470μF)