Table of Contents

- Background of factory automation

- Technical challenges faced by robot

- Solutions to overcome challenges

- Conclusion

- Recommended components

- Tool introduction

- Reference

1. Introduction and background of factory automation

The global manufacturing industry is at a significant turning point, particularly in developed countries where labor shortages due to declining birth rates and aging populations pose serious challenges. Factory automation has become an inevitable choice to address these issues. Industrial robots are gaining attention as an effective solution, offering advantages such as:

- 24/7 operational capability

- Replacement of dangerous or monotonous tasks

- High precision in operations

- Improved productivity

According to the International Federation of Robotics (IFR), the annual installations of industrial robots worldwide reached approximately 540,000 units in 2023. The total number of industrial robots operating globally in factories has reached 4,281,585 units, marking a record high with a 10% increase from the previous year.

(Figure 1: Operational stock of Industrial robots - World)

This article presents the technical challenges faced by rapidly evolving robots and the passive component solutions from Panasonic that contribute to their realization. It focuses on specific solutions for major technical challenges such as durability in harsh environments and miniaturization.

2.Technical challenges faced by robots

To further the proliferation of robots, the following challenges must be addressed, along with the necessary solutions:

Ensuring durability in harsh environments

Challenges:

- Stability in high-temperature environments

- Resistance to vibration and shock

- Long-term reliability

Solutions:

- Adoption of high heat-resistant components

- Implementation of vibration-resistant designs

- Rigorous reliability testing

Achieving miniaturization and weight reduction

Challenges:

- A large number of components

- Wiring space constraints

- Operational limitations due to increased weight

Solutions:

- Adoption of high-performance compact components

- Increased implementation density

- Use of lightweight materials

In factories and production sites, robots are commonly exposed to conditions such as high temperatures, humidity, shock, and vibration. These factors can lead to the deterioration of robot components and systems, increasing the risk of failure and necessitating improved durability. Additionally, industrial robots often require compact designs for operation in limited spaces and integration with other equipment. Addressing these challenges is crucial for the further evolution of robots.

3. Solutions to overcome challenges

Here we introduce components that contribute to solving the challenges mentioned above.

Capacitors

Panasonic's conductive polymer capacitors offer low ESR (Equivalent Series Resistance) and excellent high-frequency characteristics, providing stable performance that is unaffected by temperature or DC bias. They address issues found in conventional electrolytic and ceramic capacitors, thereby enhancing robot performance.

Miniaturization and component reduction through superior temperature characteristics

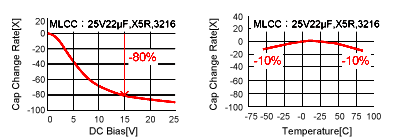

Let's compare how Panasonic capacitors contribute to miniaturization and component reduction with widely used ceramic capacitors in various applications. A characteristic of MLCCs (Multi-Layer Ceramic Capacitors) is the significant reduction in capacitance due to DC bias, as well as the decline in capacitance at high and low temperatures.

(Figure 2: MLCC DC bias characteristics, temperature characteristics)

In this example, capacitance decreases by 80% when a 15V DC voltage is applied. Additionally, high and low temperatures cause a decrease of about 10%. For instance, if 47µF of capacitance is required with a 15V DC voltage, considering the reduction, the capacitance must be based on 20% of the nominal capacitance value. In the case of a 22µF MLCC, the calculation would be as follows: 22µF × 20% = 4.4µF

47µF ÷ 4.4µF ≈ 10.7 units

In this example, to secure the required capacitance of 47µF for the circuit, more than 220µF of nominal capacitance and over 10 units of 22µF MLCC are necessary. While it is possible to reduce the number of units by selecting MLCCs with larger capacitance, the typical approach is to use multiple low-cost small-capacity MLCCs, as larger-capacitance MLCCs are limited in availability.

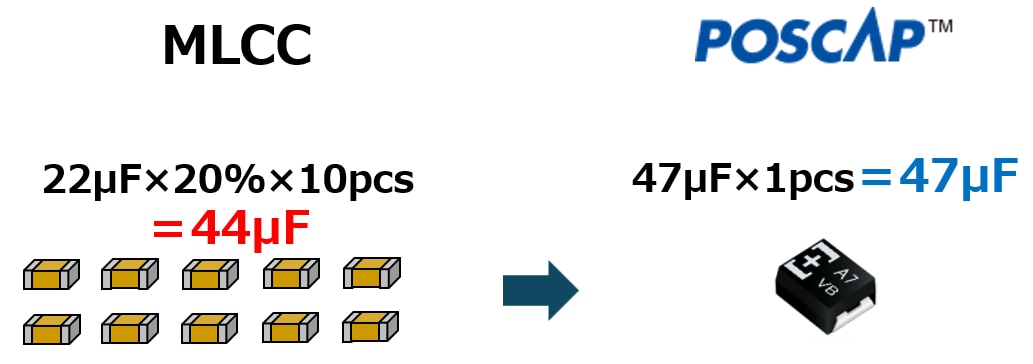

Conversely, conductive polymer capacitors do not exhibit significant reductions in capacitance due to DC bias or temperature changes. Therefore, in this example, 10 units of 22µF MLCC can be replaced with a single 47µF conductive polymer capacitor, reducing the number of components and potentially decreasing total costs, including implementation costs, as well as reducing the implementation area.

(Figure 3: Example of replacing MLCC with POSCAP)

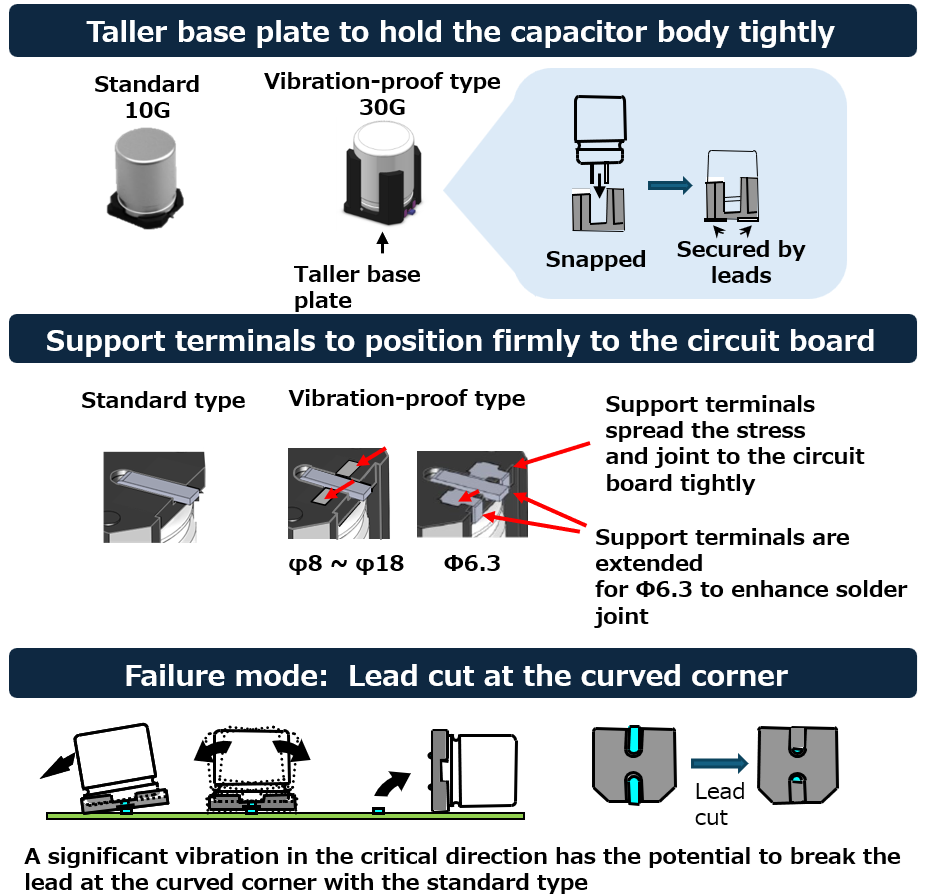

Vibration countermeasures for robotic Arms

To achieve miniaturization and weight reduction of robotic arms, there is an increasing need for compact components and component reduction, along with high vibration resistance. Panasonic's conductive polymer hybrid aluminum electrolytic capacitors support the development of new products that accommodate larger capacities and higher currents, contributing to space-saving by reducing component counts. Additionally, vibration-resistant products are available, supporting vibration acceleration up to 30G for diameters ranging from 6.3mm to 10mm.

Traditionally, when vibration reinforcement was necessary for non-vibration components, bonding (adhesive) was used to secure components. However, using vibration-resistant products can eliminate the need for vibration reinforcement, streamlining customer processes.

(Figure4: Comparison of Panasonic's Hybrid Capacitor standard and vibration-resistant products)

Supporting Stable Operation in High-Temperature Environments for Extended Periods

As the deployment of industrial robots advances, the demand for stable operation in high-temperature environments is increasing. The reliability of equipment directly impacts productivity, making the selection of high-reliability components crucial.

Aluminum Polymer Electrolytic Capacitors: SP-Cap

Panasonic’s Aluminum Polymer Electrolytic Capacitor, known as the SP-Cap, is engineered to withstand extreme temperatures, offering an impressive operational lifespan of up to 5,500 hours at 135°C. This remarkable endurance is a significant advantage for industrial robot applications that require reliability in high-temperature environments, especially those that involve constant high loads.

Polymer Tantalum Capacitors: POSCAP

Another noteworthy offering from Panasonic is the Polymer Tantalum Capacitor, commonly referred to as POSCAP. These capacitors are designed to provide robust performance in high-temperature conditions, with a guaranteed operational lifespan of up to 1,000 hours at 125°C. The POSCAP series is particularly well-suited for applications that demand high capacitance in a compact form factor, downsized to B case size, and can replace MnO2 capacitors with safety features.

Aluminum Polymer Solid OS-CON: Exceptional Longevity

Among Panasonic's offerings, the Aluminum Polymer Solid OS-CON capacitors stand out for their exceptional longevity and performance, with an operational lifespan of up to 20,000 hours at 105°C. These capacitors are specifically designed to provide extended operational life, making them ideal for applications that require long-term reliability in high-temperature environments. For example, the OS-CON SVT series features a remarkably long expected lifespan of 12.8 years at 90°C, contributing to the stable operation and longevity of robotic arms expected to be used in high-temperature and harsh environments.

Additionally, Panasonic's conductive polymer capacitors, including the SVT series, utilize conductive polymers with high electrical conductivity as electrolytes, resulting in significantly lower ESR compared to general aluminum electrolytic capacitors and tantalum capacitors. This reduction in component count and space on robot internal circuit boards contributes to the miniaturization of robots.

(Figure 5: Benefits of using low ESR products)

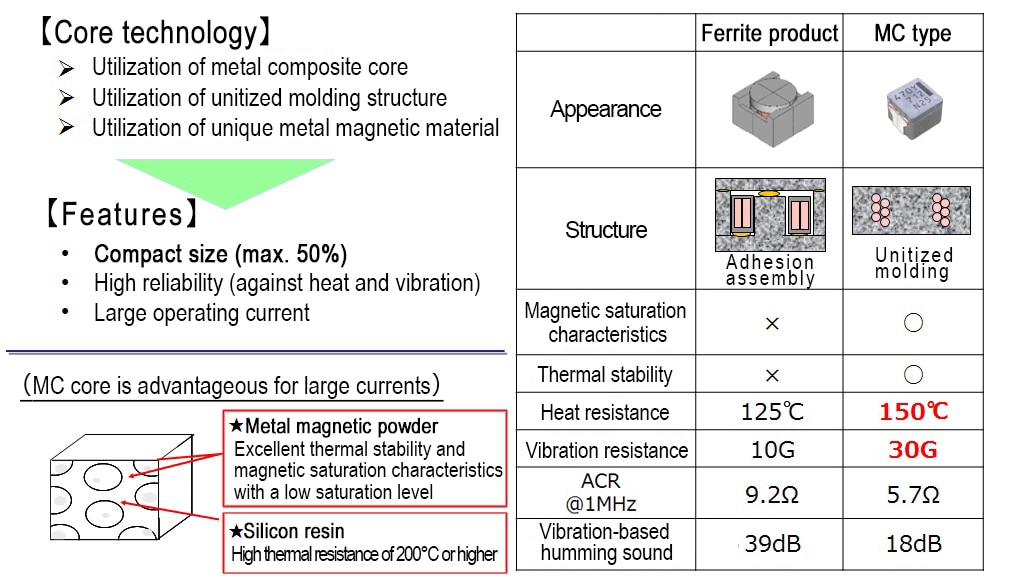

Inductors

Panasonic's Metal Composite (MC) type power inductors feature a metal composite core made from proprietary magnetic materials and an integrated molding structure. They possess superior characteristics within a small body size, offering excellent heat and vibration resistance, ensuring high reliability suitable for robotic applications.

Supporting operation in high-temperature environments with superior magnetic saturation characteristics and thermal stability

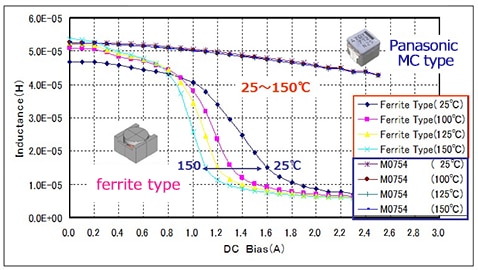

The comparison table below highlights the superior magnetic saturation characteristics, thermal stability, heat resistance, vibration resistance, and ACR (AC resistance) of MC types compared to ferrite types.

(Figure 6: Comparison of Ferrite Type and Metal Composite Type)

An example of data plotted under different conditions (25°C, 100°C, 125°C, 150°C) for the magnetic saturation characteristics (DC superimposition characteristics) of MC-type and ferrite-type inductors is presented. Magnetic saturation characteristics refer to the phenomenon where inductance sharply decreases at a specific current value when DC is applied, making them one of the key characteristics.

Generally, ferrite types are known for their pronounced saturation characteristics, as indicated by the graph, where inductance sharply decreases with increased DC bias and also varies with temperature. In contrast, Panasonic's MC type does not exhibit a rapid decrease in inductance, indicating saturation, and shows minimal variation with temperature. This is a crucial point for power inductors, which are accompanied by heat generation.

(Figure 7: MC Type vs. Ferrite Type comparison of magnetic saturation characteristics and thermal ttability)

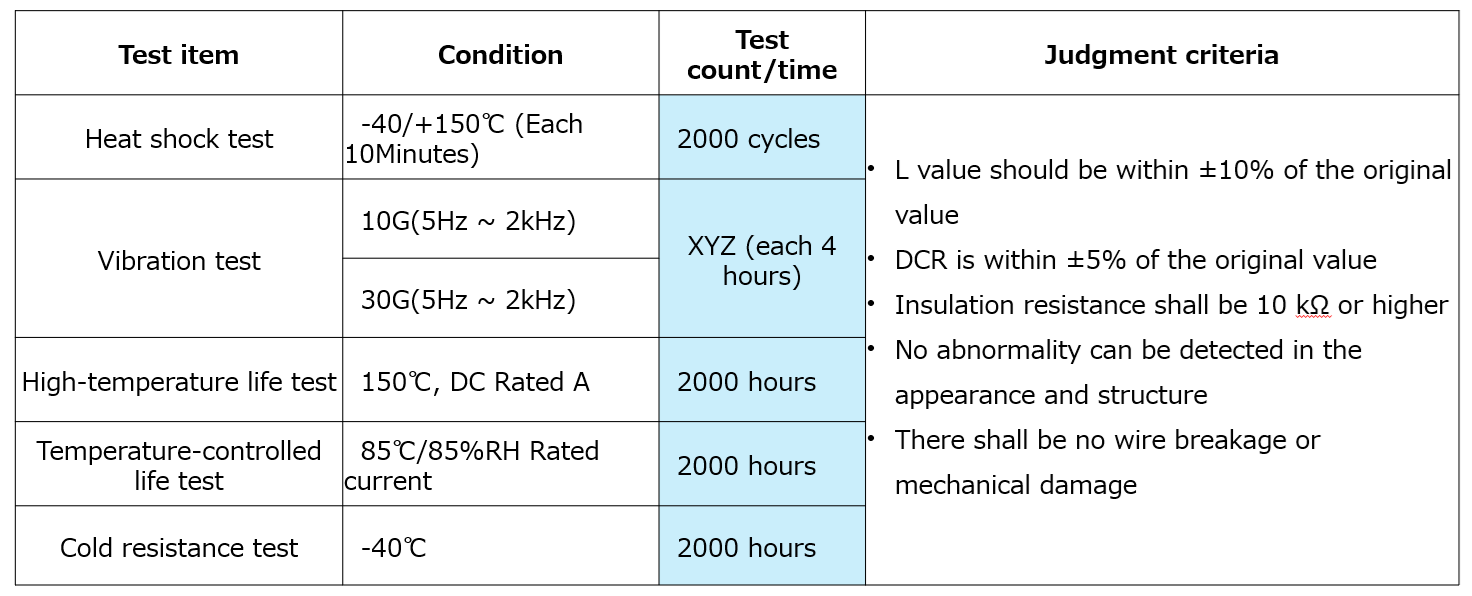

Exhibiting durability in harsh environments with superior heat and vibration resistance

Panasonic's MC type inductors ensure high reliability and are suitable for automotive applications, undergoing rigorous reliability testing. Heat shock: -40°C ⇔ 150°C for 2,000 cycles, and heat resistance at 150°C for 2,000 hours are guaranteed. Below are standard automotive test items and conditions.

(Figure 8: Reliability test example (Automotive standard)

(Figure 9: Features and strengths of vibration-resistant products)

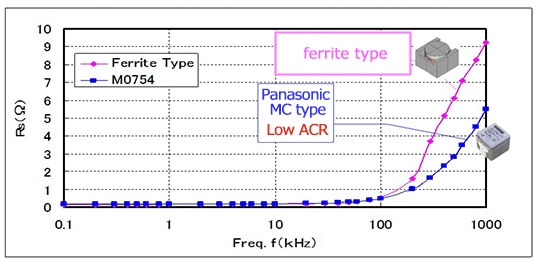

Contributing to improved energy efficiency with Low AC Resistance (ACR)

When the frequency of the current flowing through a conductor increases, the skin effect and proximity effect cause the current to concentrate on the surface of the conductor, resulting in lower density in the center and higher density on the surface. Consequently, the resistance component increases at high frequencies, and in inductors, this increased resistance component is referred to as AC resistance (ACR).

The graph below compares the AC resistance (ACR) of MC-type and ferrite-type inductors. As the frequency increases and ACR rises, AC losses increase, leading to higher heat generation. As indicated by the graph, the increase in ACR for the MC type is smaller than that for the ferrite type, indicating lower losses and heat generation even at high frequencies.

(Figure 10: Comparison of ACR-Frequency characteristics between ferrite type and metal composite type)

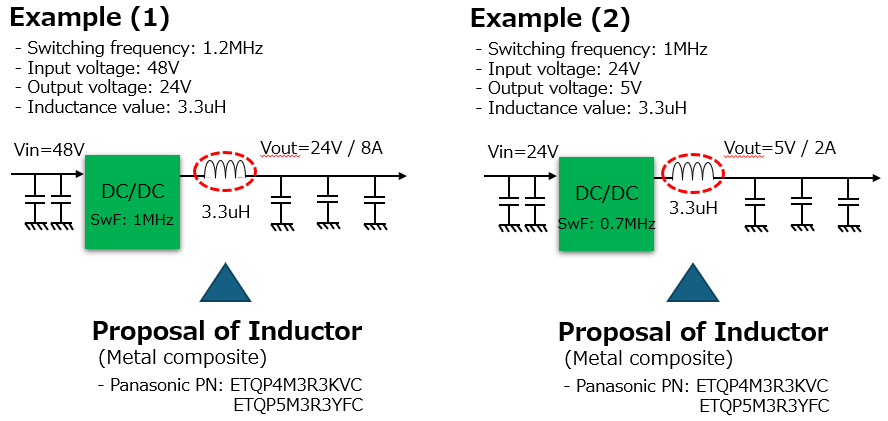

Target circuit points and benefits of Panasonic inductors

The following components are recommended for use in circuits.

(Figure 11: Target circuit points and benefits of Panasonic inductors)

Resistors

Enhancing energy efficiency with low-resistance current detection chip resistors

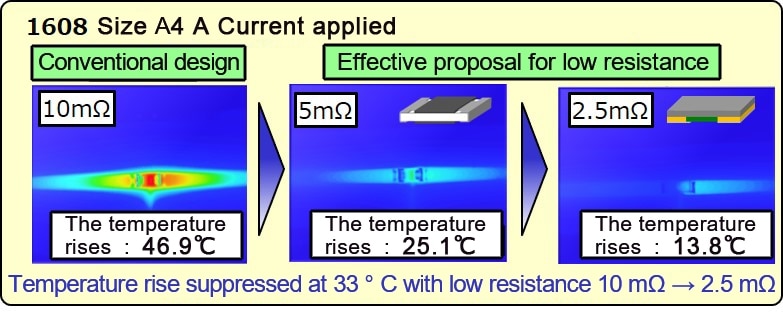

The figure below illustrates the difference in heat generation resulting from different resistance values when a current of 4A is applied. For example, reducing the resistance from 10mΩ to 2.5mΩ can decrease heat generation by approximately 33°C.

(Figure 12: Difference in heat generation due to resistance values with 4a current)

Panasonic has developed current detection chip resistors with significantly lower resistance values than conventional products. The use of these resistors reduces heat generation, thereby enhancing energy efficiency. The specific measures taken by Panasonic include:

Thick Film Type

- Achieved low resistance by forming resistive elements on both sides of the substrate and adopting a long-side electrode configuration.

- Changed the resistive element material from silver-palladium (AgPd) to a copper-nickel (CuNi) alloy, which offers lower resistivity.

Ensuring durability in harsh environments with anti-sulfur characteristics

Anti-sulfur resistors enhance reliability in environments with high sulfur content. Typical areas with elevated sulfur exposure include locations near volcanoes, hot springs, highways with high vehicle emissions, and industrial sites using cutting oils or rubber-based products. Even in general environments, sulfur can emanate from materials such as lubricants or greases used in cooling fan motors, rubber seals for packing or vibration isolation, and certain mold resins. Silicone-based coating materials can accelerate sulfur-induced corrosion (sulfuration). Thus, in such conditions, the use of chip resistors designed with sulfur resistance is essential.

Panasonic's anti-sulfur chip resistors achieve superior reliability by replacing traditional silver electrode materials with highly sulfur-resistant alternatives. Panasonic offers two resistor series tailored to specific requirements: one focused on absolute performance and another optimized for longevity, balancing performance and cost considerations.

- Gold-based electrode pursuing absolute performance

The ERJS series utilizes gold-based electrodes, recognized for their exceptional stability and superior sulfur resistance. - High palladium electrode enhancing longevity effects

The ERJU series employs a silver-palladium (AgPd) alloy electrode with high palladium content, significantly improving sulfur resistance by suppressing silver diffusion.

Below are the immersion test results comparing Panasonic’s anti-sulfur chip resistors against general-purpose resistor electrodes when immersed in sulfur-containing oil.

(Figure 13: Immersion test results comparing anti-sulfur chip resistors and general-purpose resistors in sulfur-containing oil)

In typical resistor electrodes, the low palladium content commonly results in failures (disconnections) after approximately 100 hours of sulfur exposure. In contrast, Panasonic’s ERJU series resistors, featuring high-palladium silver electrodes, exhibit no disconnection even after 3,000 hours, substantially enhancing reliability. A direct correlation exists between palladium content and time-to-disconnection; thus, the ERJU series is designed to withstand exposure exceeding 12,000 hours without failure. The ERJS series, with gold-based electrodes, demonstrates even higher reliability, showing no measurable change in resistance values after 3,000 hours.

Supporting stable operation in high temperatures with heat-resistant resistors

Standard chip resistors typically have an upper operating temperature limit of 155°C. Furthermore, resistors inherently experience self-heating (Joule heating) during operation, necessitating power derating when ambient temperatures exceed approximately 70°C. Panasonic addresses this limitation with its heat-resistant ERJH series resistors, which feature an increased maximum operating temperature of 175°C. Consequently, power derating for this series begins at a higher ambient temperature of 105°C, enabling stable, high-power operation in more demanding, high-temperature environments.

4. Conclusion

Passive components play a crucial role in enhancing the performance of a robot. The appropriate selection of capacitors, inductors, and resistors is key to addressing challenges related to durability in harsh environments and miniaturization. Panasonic is committed to contributing to the advancement of the robotics industry through innovative passive component solutions. We will also strengthen our customization options and technical support to meet the needs of our customers.

5. Recommended Components

Component |

Product Feature |

Recommend Series |

High voltage |

Large current |

Low loss |

Small size |

High resistance to heat |

High precision |

|

Conductive Polymer Aluminum Electrolytic Capacitors (SP-Cap) |

Low ESR Low ESL Long Life Small size |

JX, KX, TX, JZ, KZ, TZ series |

|

|

|

|||

|

Low ESR Small size High frequency Heat resistance High reliability |

TDC, TQC series |

|

|

|||||

|

Low ESR Long Life Excellent noise reduction |

SVPT, SVT series |

|

|

|

|

|||

|

Low ESR High withstanding Voltage High reliability Vibration resistance |

Anti-vibration type |

|

|

|

||||

|

Large current Low loss Small Size |

LP, LE series |

|

|

|

|

|

||

|

High precision High resistance to heat |

Anti-pulse: ERJP Thin film high precision: ERA*A/ERA*V Shunt: ERJ*W, ERJB/D Anti-sulfurated: ERJU/ ERJS |

|

|

|

|

6. Tool Introduction

Characteristic viewer

The characteristic viewer is a tool that graphically displays various characteristics of selected components on frequency and temperature axes. It facilitates easy verification of component characteristics such as changes in characteristic values within the operating frequency range, serving as a useful tool for component selection.

Industrial/automotive LC filter simulator

Industrial & Automotive use LC filter simulator user registration - Panasonic

The industrial/automotive LC filter simulator is a content tool that simulates attenuation characteristics when filters are configured using our power inductors and aluminum electrolytic capacitors suitable for industrial and automotive applications. Please utilize it for component selection in industrial and automotive filters.

Features:

- Filter circuit simulation is possible in π, T, and L configurations.

- Simultaneous comparison of 5 circuits is possible.

- Supports parallel and series connection of components.

- Allows output of simulation results (attenuation characteristics) in graph and CSV formats.

Lifetime calculation for Hybrid/Aluminum Electrolytic capacitor

Hybrid/Aluminum Electrolytic capacitor Estimated Lifetime Calculation Tool

Lifetime calculations provide critical insights into how Panasonic hybrid and aluminum electrolytic capacitors will perform under specific conditions, helping to predict potential failures before they occur. By analyzing factors such as temperature, voltage, load conditions, and environmental influences, engineers can estimate the expected lifespan of these capacitors.

7. Reference

International Federation of Robotics, 2024, September 24, Record of 4 Million Robots in Factories Worldwide, IFR International Federation of Robotics, https://ifr.org/ifr-press-releases/news/record-of-4-million-robots-working-in-factories-worldwide