The relevance of smart metering has increased globally during the last couple of years for different applications such as water, gas and electricity – on both the supplier and the consumer side.

Additionally, the global shipment of smart meters has reached approximately 136.45 million units in 2020, according to the Global Smart Meters Market report - and is even assumed to reach 198.53 million units by 2026, forecasting a CAGR of 6.6% from 2021 to 2026.

In most countries, it has become common sense to tackle the environmental effects caused by pollution and to strive for adopting emission control regulations. Smart grids are a promising approach in this regard – and essential in the course of this: smart meters.

Some basics: Smart meters are digital meters representing a transformative technology for the utility industry and its customers. They enable two-way communication between the meter and the supplier.

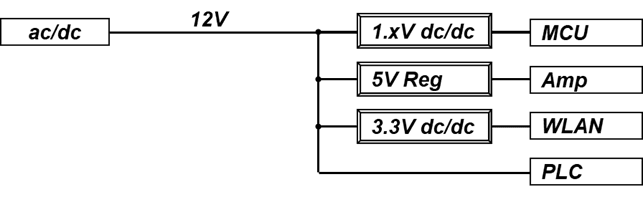

Typically, their circuit diagram is as displayed below:

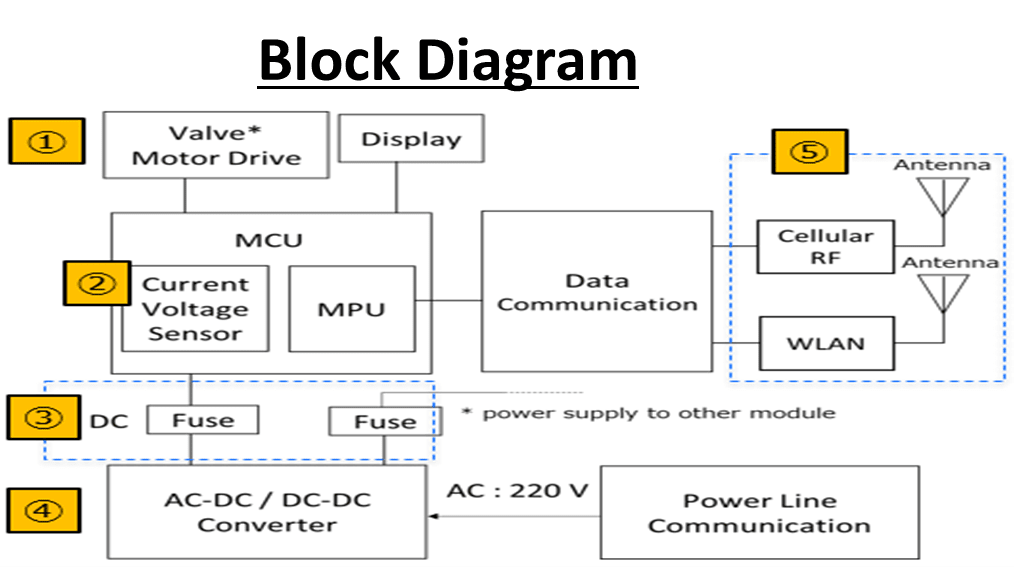

There are three main areas of a smart meter design, namely the power system, the microcontroller, and the communications interface. The power system has a switched-mode power supply and battery backup to ensure that the metering electronics remain powered even when the mainline is disabled. A Microcontroller Unit (MCU) includes an Analog-to-Digital Converter (ADC) and Digital-to-Analog Converter (DAC) to provide intelligence. And the communication interface allows the meter to interact with the rest of the grid - and in some cases the end user’s network.

Given this brief overview of basic smart meter technology, let’s take a brief trip through the world of passive components and investigate which capacitors, resistors and inductors optimally suit the needs of smart metering applications and why.

Capacitors

At the input side of the power supply circuit, film capacitors are commonly placed in EMI filters for EMI suppression purposes. In order to protect users from harm due to electric shock, X/Y classified EMI suppression film capacitors are normally required with high voltage impulse handling ability.

Taking these requirements into consideration, Panasonic Industry provides an excellent metallized PP film capacitor solution with ECQUA (safety class X2) and ECQUB (safety class X1/Y2) series for high safety and high reliability.

|

Function |

EMI Suppression |

||

|---|---|---|---|

|

Safety class |

X2 |

X1 |

Y2 |

|

Product series |

ECQUA |

ECQUB |

|

|

Voltage |

275VAC, 310VAC |

300VAC |

|

|

Capacitance |

0.0082μF to 10μF |

0.001μF to 1.0μF |

0.001μF to 0.0068μF |

|

Fuse function |

built-in |

built-in |

- |

Thanks to Panasonic’s in-house patterned metallization technology (also known as “fuse function”), ECQUA series and ECQUB series (fuse function applies to class X1 only) offer overvoltage impact reduction and therefore guarantee high safety with open failure mode.

To ensure smart meter reliability also for outdoor metering products - especially under humidity exposure - Panasonic Industry developed its enclosure sealing technology and aluminium vapor deposition to achieve a high humidity resistance.

For smoothing in the input side, typically Tantalum capacitors are employed in parallel since they have a high capacitance level. But they suffer from derating, so for a 12V line, usually 25V caps are used.

To overcome that voltage derating, Panasonic Industry offers Polymer capacitor technology to efficiently replace those tantalums. Polymer caps provide high capacitance values at a very low ESR – in this case, for a 12V line, one 16V POSCAP or OSCON would be the product of choice, combined with reliable performance in a miniaturized housing.

Replacing two Tantalums in parallel with one Polymer capacitor – have a look at the following overview.

1.xV dc/dc Input (Smoothing)

Coming to the 3rd main area of a smart meter, the communications interface, amplifier (DSL) circuit is especially important for amplifying the small signals from sensors which are later converted into digital signals that MCU can process. Panasonic Industry provides its stacked metallized film chip-type capacitors to improve the filtering ability in the amplifier circuit.

The stacked metallized PPS film capacitor ECHU(X) series feature stable capacitance characteristics against temperature, frequency and DC bias – next to a very compact size (down to 0603). And there is no need for concerns about piezoelectric effects as known from MLCCs. With its high preciseness for high-speed data transmission, ECHU(X) series is the ideal solution to optimize the design for DSL circuits.

Simplified DSL circuit for smart meter

|

Function |

Filtering |

|---|---|

|

Product series |

ECHU(X) |

|

Category temp. range |

-55℃ to 125℃ |

|

Voltage |

16VDC, 50VDC |

|

Capacitance |

0.1nF to 220nF |

|

Capacitance tolerance |

±2%, ±5% |

|

Dissipation factor (1kHz)(%) |

<0.6 |

Resistors

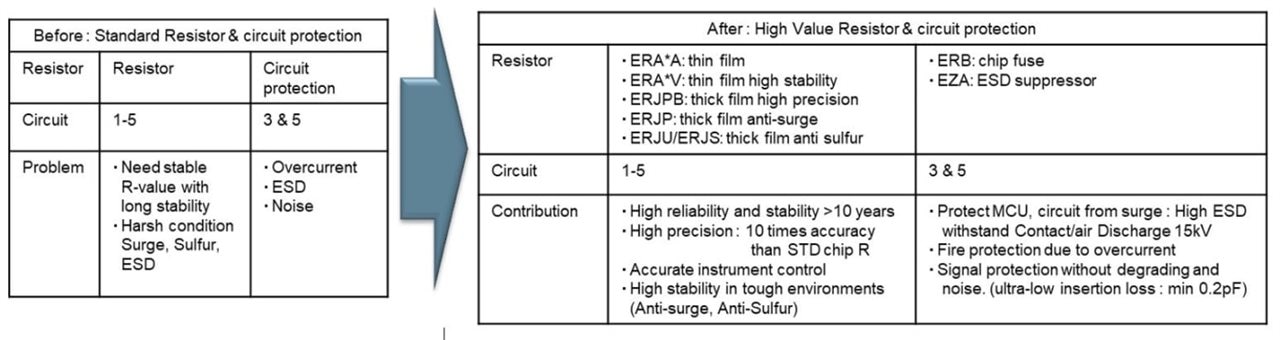

Similar to capacitors, resistors can also be used for different purposes in smart meters.

For the motor control of the valve system, it is essential to use resistors with high precision, high reliability, and high stability specs over the entire lifetime of the meter - which is of course meant to be a long one.

Additionally, in the current-voltage sensor, the output signal is highly dependent on the level of accuracy of the resistors employed. Meeting those requirements, Panasonic Industry offers a wide range of high precision resistors in thin-film (ERA* series) and thick film (ERJPB series) technology.

Looking at the DC-DC converter, it is common to use resistors with a higher voltage range and pulse-withstanding capabilities. The wide variety of Panasonic anti-pulse resistors (ERJP/T series) makes it easy to find the perfect component for each and every design.

Occasionally, smart meters are exposed to areas or conditions with tougher environments. Standard resistors sulfurize when getting in contact with above-average concentrations of oil in the air. For this, anti-sulfur resistors come into play, coming with silver or gold layers in the inner terminals to avoid sulfurization.

Panasonic’s anti-sulfur portfolio offers two major product categories, one using silver and one using gold, each in a variety of sizes and resistance values.

Circuit protection

In the power supply line, it is crucial to protect the IC from an overcurrent that might even cause a fire. Panasonic Industry chip fuses render an appropriate solution for making sure that the IC - and in the end the entire smart meter - remains safe. Furthermore, for the communication line, no matter if it is cellular RF or Wi-Fi, the signal has to be protected against ESD and noise. The signal processing, however, has to happen with the minimum of signal degrading. Panasonic ESD suppressors can withstand a high amount of ESD with minimum degrading of the signal and minimum insertion loss (S21) of 0.4 pF.

Inductors

Next to capacitors, the DC/DC input requires also an inductance for current smoothing.

An established technology would be THT wire-wound inductors with a ferrite core. They, however, require considerable space as well as two reflow processes for mounting on the PCB.

Here, Panasonic Industry offers a more elegant solution with the ETQP_L and ETQP_M series, which both provide a much higher energy density that leads to a remarkably higher efficiency due to their innovative metal composite technology.

Therefore, both series only require half the space on the PCB compared to the conventional THT wire-wound inductor. Thanks to SMD mounting, only one reflow process is needed – which of course saves further production time and costs. The images below show an example of the possible differences on a PCB.

1.xV dc/dc Input (Smoothing)

Summary

The high expectations regarding compact housings, high performance and lifetime: Next-gen smart metering applications meet them, if the used components are the right ones. Manufacturers like Panasonic Industry offer the entire range of passive components, dedicated to the reliability and functionality of tomorrows smart metering innovations.