Table of Contents

Background: Battery Management Systems in general

In an era where energy efficiency and sustainability are essential, Battery Management Systems (BMS) have emerged as critical components in both industrial and automotive applications. These systems play a vital role in monitoring, controlling, and optimizing battery performance, ensuring safety, longevity, and reliability. As the demand for electric vehicles (EVs) and renewable energy storage solutions continues to rise, the relevance of robust BMS technology cannot be overstated. In the automotive sector, BMS not only enhances vehicle performance but also contributes to the overall safety and efficiency of electric drivetrains. Similarly, in industrial applications, effective battery management is essential for maximizing uptime and operational efficiency in energy storage systems. Panasonic's portfolio of passive components for BMS is designed to meet these growing demands, providing innovative solutions that support the advancement of battery technology across various industries.

Technical challenges

Durability in harsh environments

As the complexity of Battery Management Systems (BMS) increases, several technical challenges emerge that must be addressed to ensure optimal performance and reliability. One significant challenge is durability in harsh environments, including extreme temperatures, high humidity and different vibration profiles. This is particularly critical in automotive applications, in which components are exposed to this kind of conditions over extended periods.

Miniaturization and weight reduction

Another pressing challenge is the need for miniaturization and weight reduction. As electric vehicles and industrial systems strive for greater efficiency, a growing demand for compact and lightweight components that do not compromise on performance is observed. This trend is essential for enhancing energy density and overall system efficiency, making it crucial for manufacturers to innovate continuously.

To tackle these challenges, Panasonic's range of capacitors, resistors, and inductors is designed with advanced materials and technologies that enhance durability and performance while supporting miniaturization. In the following sections, we will explore how these passive components contribute to overcoming the technical hurdles faced in the development of effective and reliable BMS solutions.

Solutions to overcome challenges

Panasonic's offer of resistors

In the ecosystem of Battery Management Systems (BMS) for industrial and automotive applications, the importance of precision and reliability cannot be overstated. Among the key components that facilitate these attributes are resistors, particularly thin and thick film resistors. Panasonic has developed a comprehensive range of these technologies, each designed to meet the specific demands of high-performance battery management systems.

Thin Film Resistors: Precision and performance

Thin film resistors play an essential role in voltage measurement and control within battery management systems. These resistors are typically used in series configurations, allowing them to withstand the high voltages that may occur during operation. The ability to measure and control voltage accurately is crucial, especially in environments where overvoltage conditions can arise. While Panasonic offers thin film resistors that can handle higher voltage ranges, it is essential to clarify that these are not classified as "high voltage" components in the traditional sense. Instead, they are designed for higher voltage applications, emphasizing precision rather than extreme voltage tolerance. An additional consideration is that ERA*V/K/P types feature an absorbable layer, which helps them withstand more temperature cycles. This characteristic can also be beneficial, as it may enhance their durability and reliability in demanding thermal environments. This distinction is vital for engineers who require components that provide accurate readings without compromising on performance.

Thick Film Resistors: Robustness and versatility

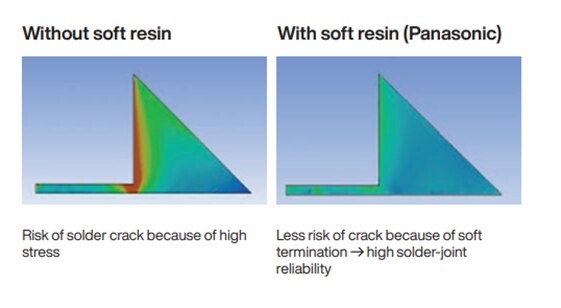

In addition to thin film resistors, Panasonic also provides a variety of thick film resistor technology. Panasonic thick film resistors are engineered to handle significant thermal and electrical stresses, making them suitable for demanding applications. One of the standout features of Panasonic's thick film resistors is the integrated soft termination, which is automatically included in components sized from 0201 and larger.

The soft termination technology is a game-changer in the market. It allows the resistor to expand and contract with temperature fluctuations, thereby mitigating the risk of solder joint failure. In battery management systems, in which components are subjected to varying temperatures and currents, without soft termination, solder joints can become brittle and fail, leading to potential system malfunctions.

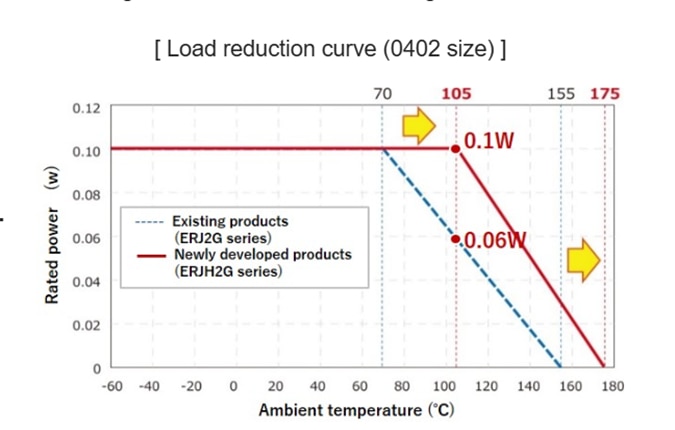

Thick Film Resistors: High temperature and high current capabilities

Part of Panasonic thick film resistors is high temperature technology, capable of withstanding maximum temperatures of up to 175°C. This capability is crucial for Battery Management Systems that may experience elevated temperatures due to high current loads. The concept of derating—with which the power capability of a resistor is reduced instead of 70° C at higher temperature of 105° C—becomes less of a concern and is particularly beneficial with high temperature resistor technology.

For instance, in a typical battery management scenario, temperatures can reach between 110°C to 125°C. Panasonic's thick film resistors allow for less power derating compared to standard components, ensuring that they can handle larger currents without compromising performance. This robustness makes them ideal for applications where reliability and durability are of vital necessity.

Conclusion

In summary, Panasonic's offerings of thin and thick film resistors are integral to the functionality and reliability of Battery Management Systems in industrial and automotive contexts. The precision of thin film resistors, combined with the robustness and thermal resilience of thick film resistors, ensures that these components can meet the rigorous demands of modern battery technologies. As the industry continues to evolve, the role of these passive components will remain crucial in supporting the performance and safety of battery management systems.

Panasonic's inductors for Battery Management Systems

Panasonic offers inductors, specifically designed to monitor and control battery status, ensuring optimal performance and safety in these advanced systems.

The importance of inductors in BMS

Current regulation

Inductors play a critical role in regulating and controlling current flow within battery management systems. This regulation is essential for both charging and discharging processes of the battery. By smoothing out fluctuations in current, inductors help maintain stable operation, which is vital for the longevity and efficiency of the battery. This capability is particularly important in applications where rapid changes in current demand can occur, such as during acceleration or regenerative braking in electric vehicles.

EMI/EMC protection

Another significant function of inductors in BMS is their ability to suppress electromagnetic interference (EMI) and ensure compliance with electromagnetic compatibility (EMC) standards. As electric vehicles incorporate various electronic components, managing EMI becomes crucial to prevent disruptions in performance and maintain the integrity of sensitive electronic systems. Panasonic's inductors are designed to minimize differential mode noise, thereby enhancing the overall reliability and safety of the battery management system.

Safety features

Inductors also contribute to the safety of Battery Management Systems by protecting against overcharging, deep discharging, and other potential hazards. By controlling the current flow - and at the same time withstanding high currentsinductors are acting as a buffer in the circuit and help prevent conditions that could lead to battery damage or failure. This safety feature is paramount in automotive applications, where the consequences of battery failure can be severe.

Panasonic's LP inductors for BMS

High quality heat resistance with upgraded efficiency

One of the standout offerings from Panasonic is the Power Choke Coils, which are surface mount power inductors known for their high heat resistance and exceptional DC bias characteristics. These metal composite inductors utilize a Hi-BS ferrous alloy magnetic material, ensuring reliability even in high-temperature environments.

Additionally, they exhibit a high tolerance for vibration or high ripple current capability, depending on the series, making them suitable for the demanding conditions often encountered in automotive applications.

These Power Choke Coils are extremely efficient, featuring low DC resistance (DCR) and, depending on the specific series, reduced eddy current losses. This efficiency not only enhances the performance of the power circuit but also simplifies the thermal design process, contributing to a more compact and effective battery management system.

Features and benefits of Power Inductors for automotive applications

Miniaturization of ECU power circuits: With their small case size and high current capability, Panasonic's inductors facilitate the miniaturization of electronic control unit (ECU) power circuits, allowing for more compact designs without sacrificing performance.

Low loss characteristics: The low loss characteristics of these inductors enable high efficiency in the power circuits of ECUs, which is essential for optimizing battery usage and extending the range of electric vehicles.

High reliability in severe conditions: The metal composite monolithic structure of Panasonic's inductors ensures high reliability, making them suitable for applications in harsh environmental conditions. Panasonic Industry offers anti-vibration power inductor components capable to withstand up to 30G and 50G.

Conclusion

In conclusion, especially Panasonic's inductors can play a vital role in the functionality and safety of Battery Management Systems for electric and hybrid vehicles. As the automotive industry continues to evolve, the significance of high-quality passive components like Panasonic's inductors will only grow, supporting the transition to more efficient and sustainable electric mobility solutions.

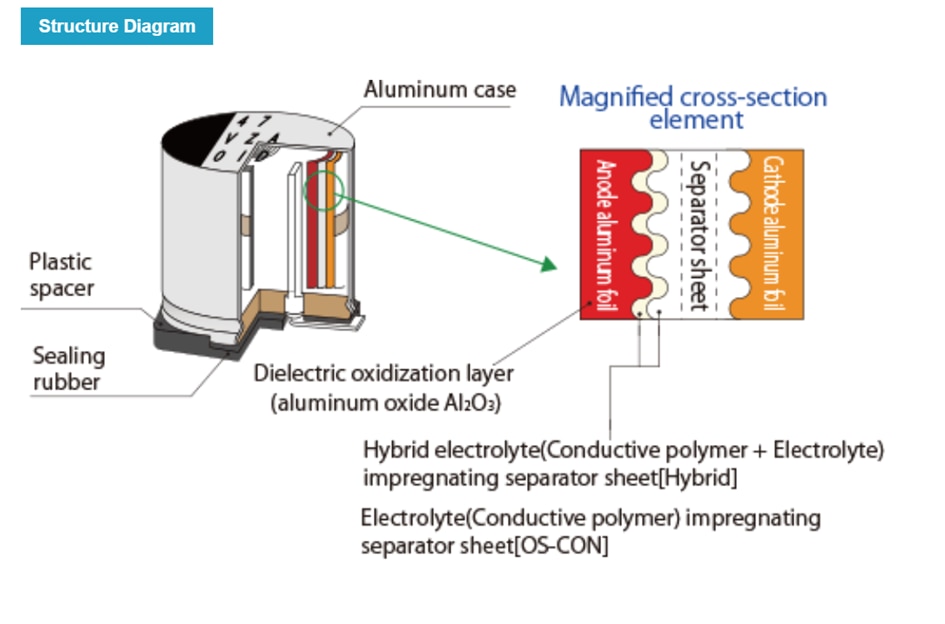

Panasonic's Hybrid Capacitors

Panasonic's hybrid capacitors emerge is a vital component for BMS, combining the advantages of aluminum electrolytic and polymer capacitors. The essential advantage are their low leakage currents despite having high ripple current capability.

These hybrid capacitors are engineered to meet the demanding requirements especially of electric vehicles (EVs) and hybrid electric vehicles (HEVs), ensuring optimal performance, reliability, and safety.

Key Features of Panasonic's Hybrid Capacitors

Panasonic's hybrid capacitors are designed to deliver exceptional performance in various applications, particularly in battery management systems. Their key features include:

- Low Equivalent Series Resistance (ESR): The low ESR of hybrid capacitors allows for efficient energy transfer, reducing heat generation and improving overall system efficiency. This characteristic is crucial in applications where rapid charging and discharging occur.

- High Reliability: These capacitors are engineered for stability and durability, ensuring a high lifetime at application temperature and voltage. Their consistent performance under rigorous automotive conditions is essential for the safety and longevity of battery systems.

- High Voltage and Large Current Handling: Panasonic's hybrid capacitors are designed to withstand voltage levels up to 80V while handling large currents, making them suitable for demanding applications in BMS and BDU (Battery Disconnect Unit) systems. This capability is vital for managing the energy flow in electric and hybrid vehicles.

- High Heat Resistance: Featuring a robust construction that tolerates elevated temperatures, these hybrid capacitors operate effectively in high-heat environments, making them suitable for demanding applications such as automotive settings with frequent temperature fluctuations, meeting temperatures of up to 150°C

Benefits of Hybrid Capacitors for BMS and BDU Ecosystem

- Compact Design: One of the standout advantages of Panasonic's hybrid capacitors in comparison to standard products is the compact size of new miniaturization series, allowing smaller footprints compared to the standard aluminum technology - and hence more efficient designs in battery management and distribution units.

- Vibration-Proof Options: Panasonic offers vibration-resistant hybrid capacitors, which are crucial for automotive applications where components are subjected to continuous movement and vibrations. These capacitors can withstand up to 30G of vibration, and even without an anti-vibration plate, they can handle vibrations of up to 10G.

- Stable Electric Characteristics at High Frequencies: Hybrid capacitors offer stable electrical characteristics that are generally more reliable than aluminum capacitors, making them suitable for various applications within BMS and BDU systems. While they may not necessarily operate at higher frequencies, their stability ensures accurate measurements and dependable performance in dynamic environments.

- Enhanced Ripple Capability: The ability to handle ripple currents effectively is another significant benefit of Panasonic's hybrid capacitors. This characteristic helps to prevent overheating and potential failure, contributing to the overall safety and reliability of battery management systems.

Conclusion

In summary, Panasonic's hybrid capacitors are a critical component in the functionality and reliability of Battery Management Systems and battery distribution units. In many aspects and specifications, these capacitors meet the demanding challenges of the “electrification of everything” – and the role of high-quality hybrid capacitors will remain essential in supporting the performance, safety, and efficiency of battery systems.