AC/DC converter trends and GaN

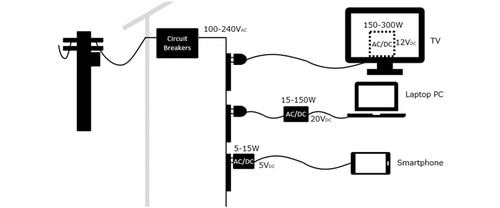

Different kinds of electronic devices employ AC/DC converters as instrument to transform commercial AC power into DC power. They are necessary since the majority of electrical loads operate on DC rather than AC voltages. The size of an AC/DC converter varies depending on how much power the device needs. From the perspectives of saving space and portability, the smaller the size as compared to the same power, the better.

Downsizing has historically been a gradual process ever since AC/DC converters switched from linear to switching approaches.

But as is sometimes the case with AC adapters for notebook PCs, there have been notable reductions in size in recent years.

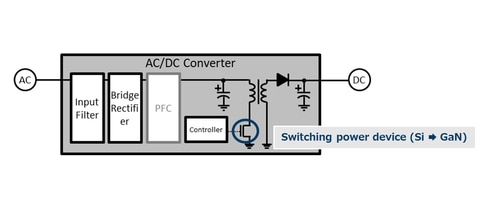

Such dramatic advances are frequently brought about by the introduction of low-loss GaN (gallium nitride) as a switching element in place of traditional Si, in addition to ongoing improvements in circuit topology.

Since approximately the year 2000, GaN has been used in power supplies. But the use of practical GaN has been gaining tremendous momentum in recent years.

Due to societal developments including the rise of mobile work and power shortages, there has been a growing demand for smaller size and improved efficiency. Additionally, GaN's own quality and productivity improvements have been matched.

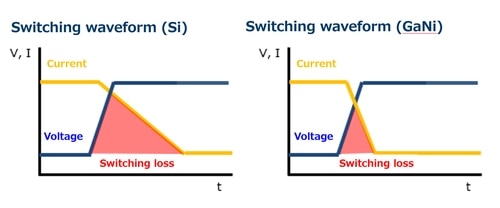

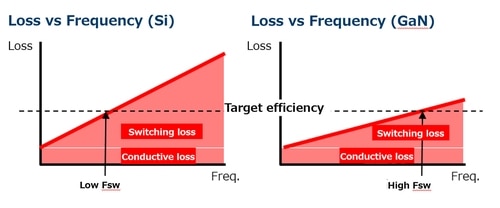

GaN switching elements have lower switching losses than Si switching elements because they switch more quickly. As a result, if the switching frequency is kept constant compared to conventional Si, efficiency will be increased, heat will be lowered, and heat dissipation components will be made simpler.

Additionally, if employing smaller passive components, it is acceptable to use a higher switching frequency. GaN can maintain the same high efficiency that Si offered at a low switching frequency, even at greater switching frequencies.

Modern power supply designs are generally regarded as acceptable if they maintain the high power efficiency that earlier technologies attained. GaN's low loss advantage therefore frequently causes designs to be scaled down.

Advantages of polymer capacitors

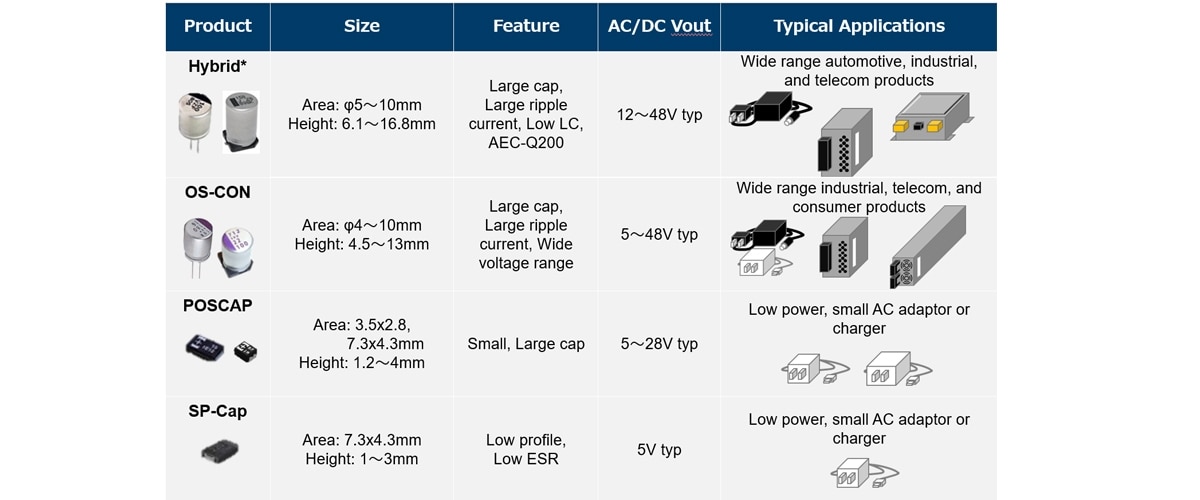

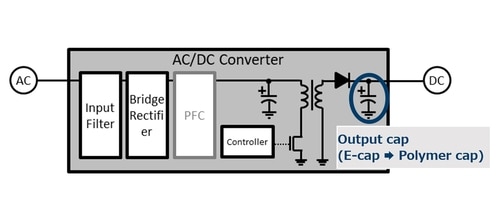

In order to reduce the size of the output capacitors for AC/DC converters that use GaN switches, Panasonic Industry offers a large selection of suitable polymer capacitors.

Let's first examine the operation of an output capacitor.

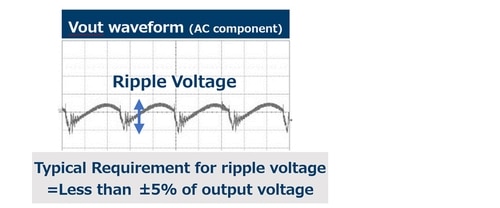

The output capacitor adds to the clean DC current output to the next circuit by absorbing the ripple current of the AC/DC converter. The capacitor will always produce ripple voltage when it takes in ripple current. This ripple voltage must be less than the limit values established for the application's safe functioning during design verification, which are typically less than 5% of the output voltage.

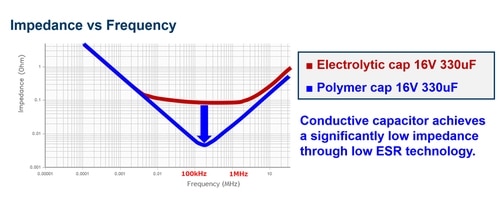

The impedance of the capacitor is the primary component for obtaining minimal ripple on a DC output voltage. The fundamental relationship is ripple voltage = ripple current x impedance (V=I*Z). Therefore, it is best to utilize capacitors with the lowest possible impedance at the switching frequency (where ripple current occurs).

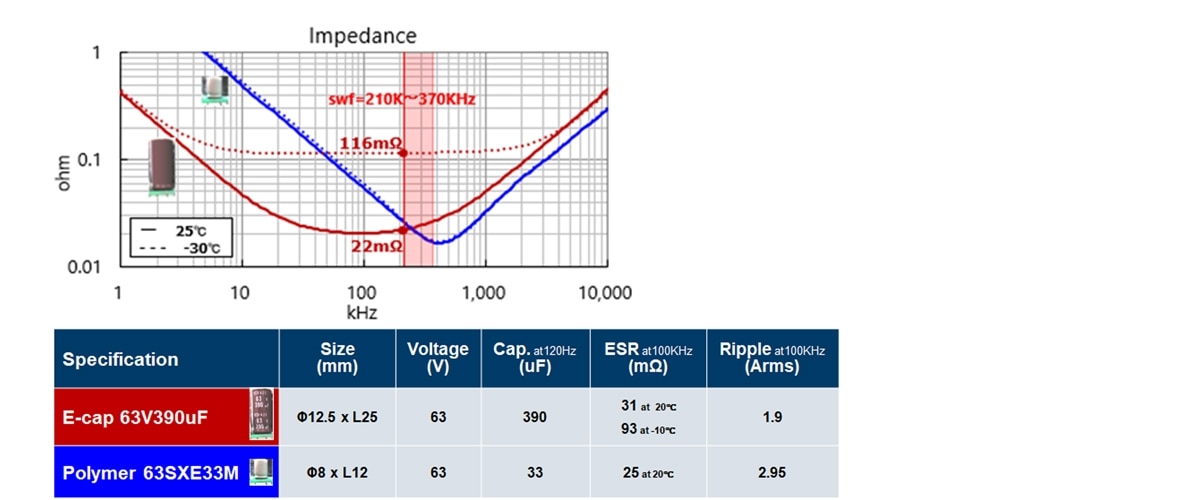

GaN's reduced switching loss makes it possible to employ switching frequencies up to 500 kHz, compared to traditional Si's 100 kHz.

Polymer capacitors have a far lower impedance in this high-frequency region than with the more common liquid electrolytic capacitors. As a result, polymer capacitors can significantly lower ripple voltages, making them the optimum output capacitors for AC/DC converter systems that use GaN.

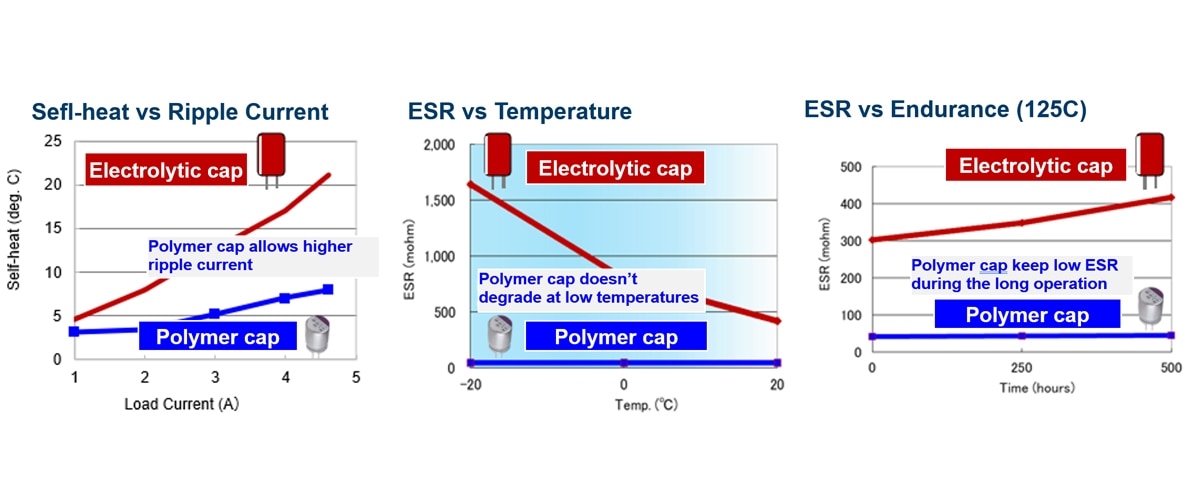

A low ESR conductive polymer substance is used as the electrolyte to provide polymer capacitors their low impedance.

Because of the low ESR, it can withstand more ripple currents than electrolytic capacitors.

Additionally, unlike liquid electrolytic capacitors, conductive polymer has a solid electrolyte, therefore its properties do not degrade over time or in low-temperature environments. These benefits of polymer capacitors influence client designs in various ways.

Comparison with electrolytic capacitors in high-frequency AC/DC converters

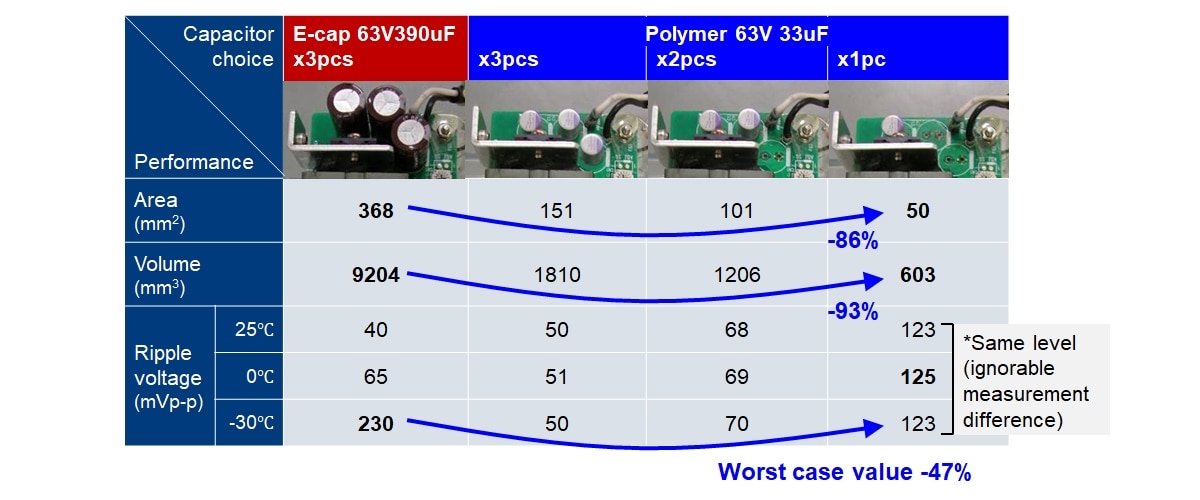

In some circumstances, raising the switching frequency can lower capacitance, which can result in significant cost and size reductions. Let's discuss one example of this.

The high-frequency AC/DC converter used in the evaluation example below operates between 200 and 400 kHz. Compared to electrolytic capacitors, polymer capacitors are able to implement the design with a significantly smaller area and fewer components.

This is a result of the aforementioned polymer capacitor's good temperature and frequency properties.

1. Capacitor characteristics comparison

Tested Device:

Electrolytic capacitor 63V 390uF vs Polymer capacitor 63V 33uF

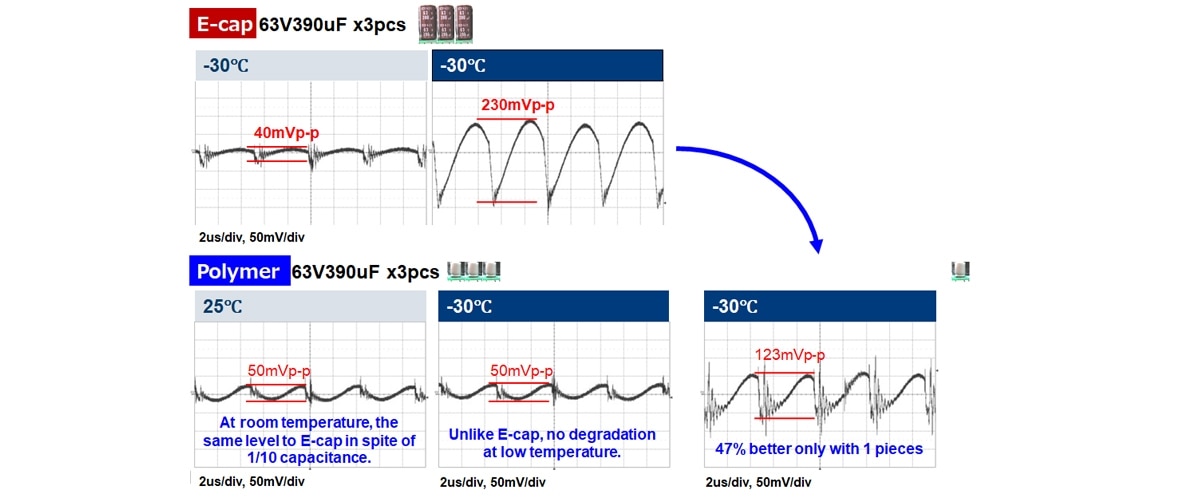

2. Circuit performance comparison

AC/DC converter specs

- Output power 150W

- Output voltage 48V

- Allowable voltage fluctuation range ±400mV, Fsw 210k-370kHz, LCC topology

- Operating temperature range -30°C to +65°C

- Expected life 50,000 hours (5.7 years)

Test point

At 48V output of the AC/DC converter

Test content

Measure the output ripple voltage at a maximum load of 3.2A including at lowest operating temperature for the worst condition.

Compare the measurement result between the originally equipped electrolytic capacitor 63V 390uF x 3 and proposed Panasonic polymer capacitor 63V 33uF x 1-3.

Even though the polymer capacitor has a smaller capacitance, its excellent frequency characteristics suppress ripple voltages to the same level.

When looking at the lowest operating temperature -30°C, it shows a possibility to design only with a single polymer capacitor.

And this will be stable even at the end of life (after 50,000 hours).

= Reduced mounting area / cost / longer life

Summary of evaluation results

Panasonic polymer capacitors

The need for these high-frequency AC/DC converters, which is growing with GaN adaptations, is being met by Panasonic.

Panasonic is a leader in polymer capacitors and offers a range of solutions up to 100V that make use of our special high-performance and high-reliability technology. They are extensively utilized for 48V output for network equipment, 24V output for industrial equipment, and 5-20V output, which is commonly used in consumer devices.

In response to current issues with power shortages, more and more devices—such as cars, data centers, and USB-PD—are switching to high-efficiency 48V power distribution. Then, in addition to GaN, polymer capacitors will be more active.

*Hybrid=Polymer+Liquid electrolyte