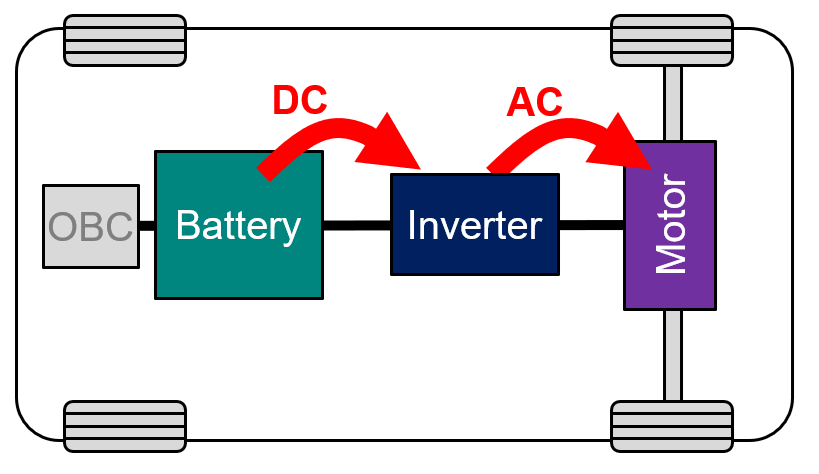

As electric vehicles (EVs) continue to reshape the automotive landscape, one component plays a pivotal role in driving performance and efficiency: the inverter. This essential device converts direct current (DC) from the battery into alternating current (AC) to power the motor. In this article, we’ll explore the role of inverters in EVs, key design requirements, and how Panasonic’s advanced electronic components are enabling the future of e-mobility.

What Is an EV Inverter?

An inverter is a DC/AC converter that transforms the battery’s direct current into alternating current, which is required by most EV traction motors. Without an inverter, the motor cannot operate. Depending on the vehicle type, one or more inverters may be installed—especially in models with in-wheel motors, where each wheel is powered independently.

Motor Types and the Need for Inverters

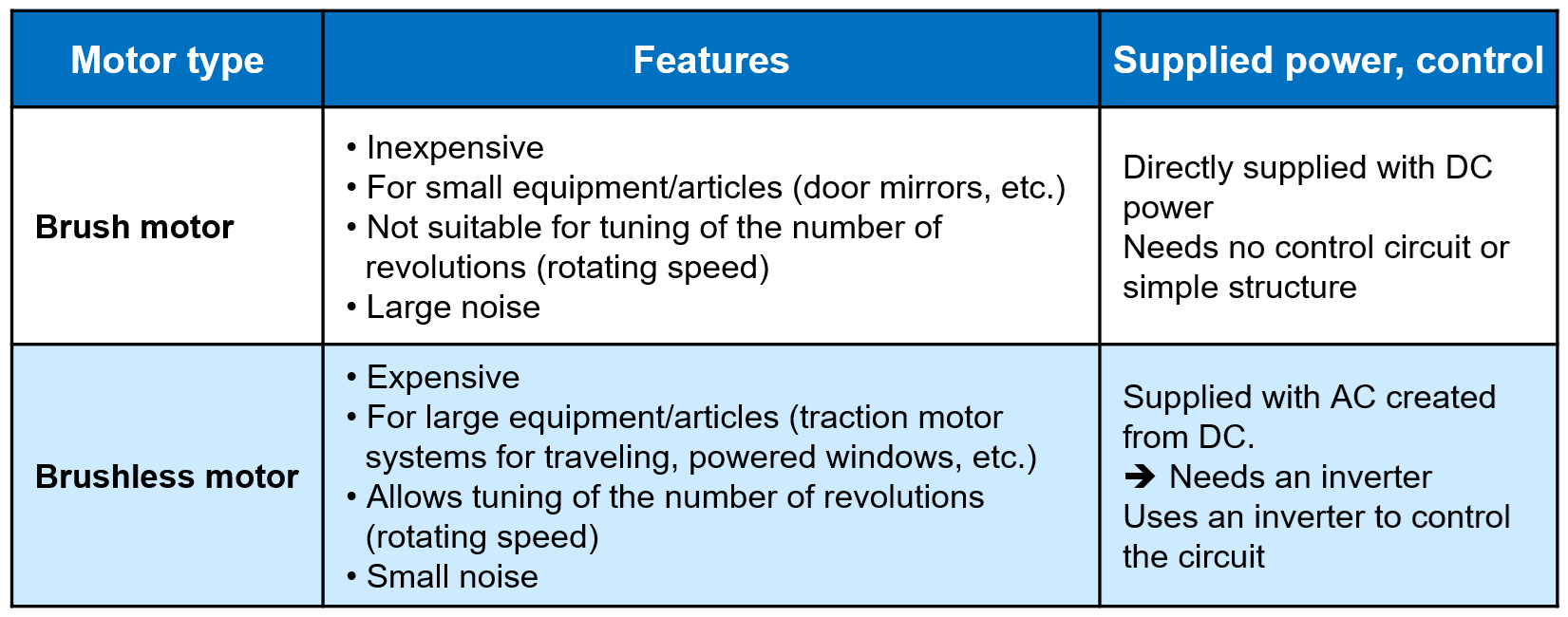

EV motors fall into two main categories:

- Brush Motors: Simple and cost-effective, these run on DC and are typically used in small devices.

- Brushless Motors: Preferred for EVs due to their high efficiency and precise speed control. These require AC power, making inverters indispensable.

Market Trends: Why High-Performance Inverters Matter

With the rapid adoption of EVs, the demand for high-output inverters is surging. Key trends include:

1. High Power Output

Modern EVs require inverters that can handle voltages up to 800V and large currents. This demands robust semiconductor components capable of managing high power without compromising reliability.

2. Heat Resistance

As components shrink, heat density increases. High thermal resistance is essential to prevent degradation and ensure long-term performance.

3. Compact & Lightweight Design

While power output increases, size and weight must decrease to maintain vehicle efficiency. Panasonic addresses this challenge with miniaturized, high-performance components.

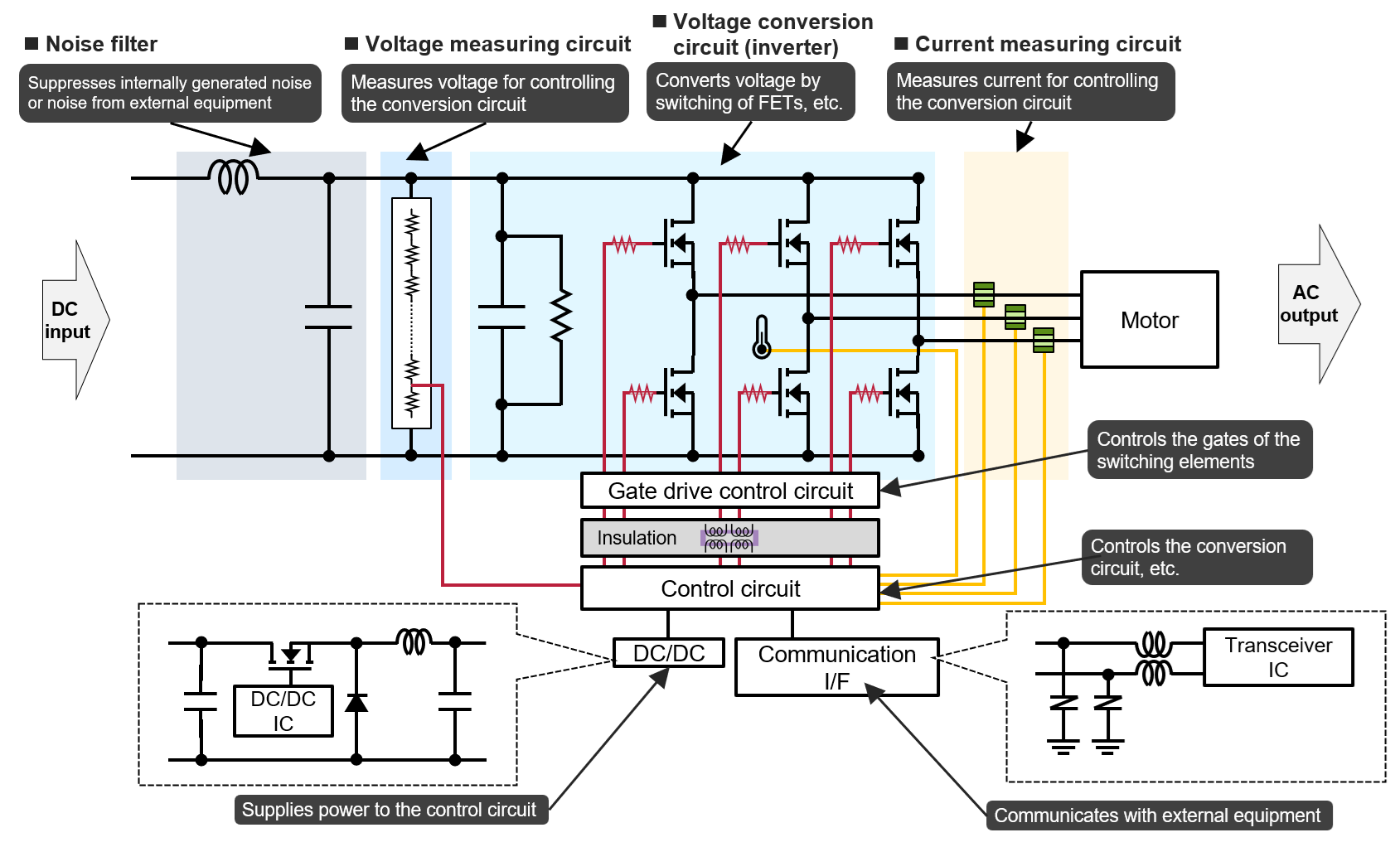

Inside the Inverter: Key Circuit Blocks

An EV inverter is a complex system composed of several critical circuits:

- Noise Filter: Suppresses internal and external electromagnetic interference.

- Voltage Measuring Circuit: Monitors input voltage for precise control.

- Voltage Conversion Circuit: Uses switching elements (e.g., FETs) to convert voltage, with film capacitors and resistors to manage noise and energy discharge.

- Current Measuring Circuit: Ensures accurate current control.

- Control Circuit: Coordinates the entire conversion process.

- DC/DC Converter: Powers the control circuit using hybrid aluminum electrolytic capacitors and automotive-grade inductors.

- Communication Interface (CAN, Ethernet): Protected by chip varistors to guard against static and noise.

Panasonic’s Component Solutions for EV Inverters

Panasonic Industry offers a comprehensive lineup of components tailored for inverter applications, including:

- Film Capacitors: Essential for suppressing electromagnetic noise and stabilizing voltage fluctuations.

- NTC Thermistors: Used for precise temperature monitoring and thermal protection of switching elements.

- Hybrid Aluminum Electrolytic Capacitors: Deliver stable power in DC/DC converter circuits, ensuring reliable operation under high-load conditions.

- Power Inductors: Automotive-grade inductors optimized for efficient voltage conversion and noise filtering.

- Chip Varistors: Provide electrostatic discharge (ESD) protection for communication interfaces such as CAN and Ethernet.

- Chip Resistors: Crucial for gate control in switching circuits, noise suppression, and energy discharge management. These resistors help stabilize inverter operation and contribute to overall system reliability.

These components are engineered to meet the demands of high power, thermal resilience, and compact design, making them ideal for next-generation EV platforms.

Conclusion: Driving the Future with Panasonic

As EV technology evolves, so too must the components that power it. Panasonic’s advanced solutions for inverters help engineers meet the challenges of high performance, miniaturization, and reliability. Whether you're designing for a compact city EV or a high-performance electric SUV, Panasonic has the components to bring your vision to life.

| Component | Feature | High Voltage | Large Current | Low Loss | Miniaturization | High Heat Resistance | High Precision |

| Film Capacitors | High reliability |  |

|

||||

| Conductive Polymer Hybrid Aluminum Electrolytic Capacitor | Low ESR High reliability |

|

|

|

|

|

|

| Power Inductor for Automotive Application | Large current, low loss High reliability |

|

|

|

|

||

| Chip Resistor | High precision, high resistance to heat |  |

|

|

|

|

|

| Chip Varistor | Small and light |  |

|||||

| NTC thermistor | Small, high resistance to heat |  |

|

|