Essential Power Conversion for Safe and Efficient EV Operation

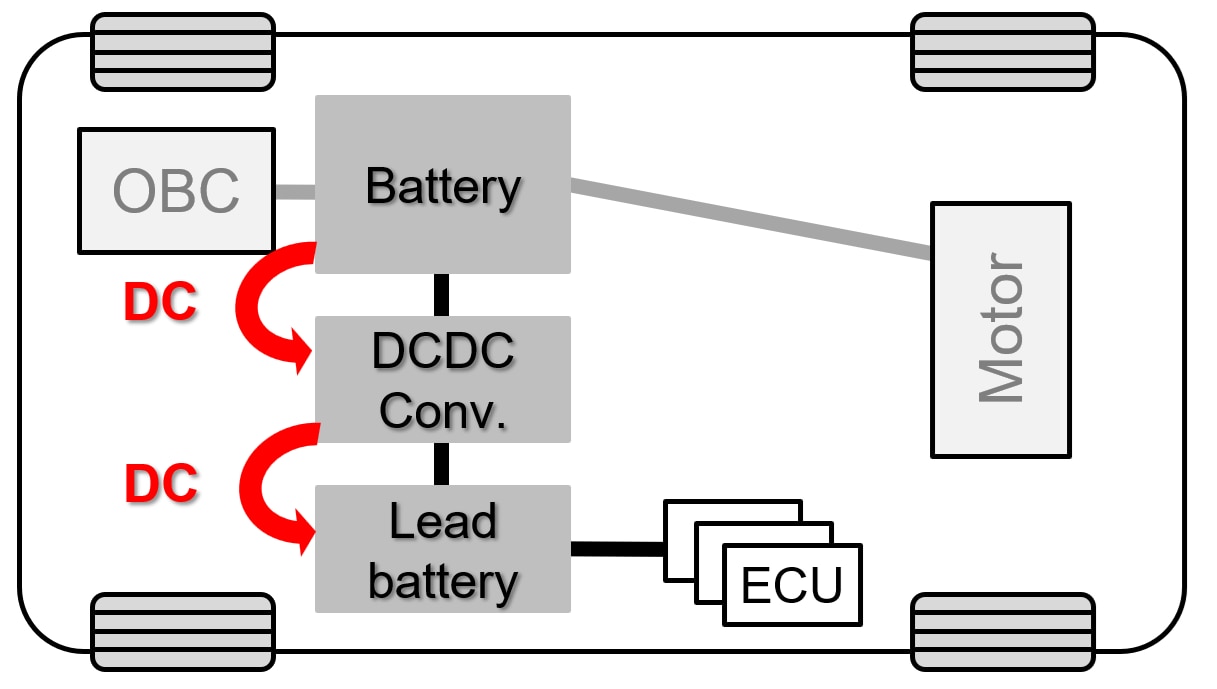

Electric vehicles (EVs) rely on two types of onboard batteries: a high-voltage lithium-ion battery and a low-voltage lead-acid battery. While the lithium-ion battery powers the drive motor and is charged via external charging stations, the lead-acid battery supports auxiliary systems and must be charged internally—from the lithium-ion battery. This is where the DC/DC converter plays a critical role: it transforms high-voltage DC power into low-voltage DC power, enabling safe and efficient operation of various vehicle systems.

Why DC/DC Converters Are Essential in EVs

Modern EVs are packed with electronic components—from ECUs and cameras to lighting systems—all of which operate on low-voltage power. However, the main drive motor requires high-voltage power (typically 400V or more) to reduce current flow and improve energy efficiency. Without a DC/DC converter, these systems would be incompatible with the vehicle’s power architecture.

High vs. Low Voltage Applications

- High Voltage (400V+): Used for drive motors and other high-power systems. High voltage reduces current, minimizing energy loss and improving efficiency.

- Low Voltage (12V): Powers auxiliary systems such as infotainment, lighting, and control circuits—even within high-voltage devices.

Why 12V Is the Standard

The 12V standard originates from early automotive systems that used lead-acid batteries to power starter motors. Today, passenger vehicles still use 12V systems (6 cells × 2.1V), while larger vehicles like trucks often use 24V systems for higher torque requirements.

Market Trends and Future Outlook

As EV adoption accelerates globally, the demand for DC/DC converters is expected to rise significantly. Additionally, the electrification of more vehicle systems is driving the need for:

- Higher output power

- Smaller form factors

- Greater thermal resistance

- Higher precision and reliability

Panasonic Industry is at the forefront of this evolution, offering a comprehensive lineup of automotive-grade components designed to meet these demanding requirements.

DC/DC Converter Circuit Architecture

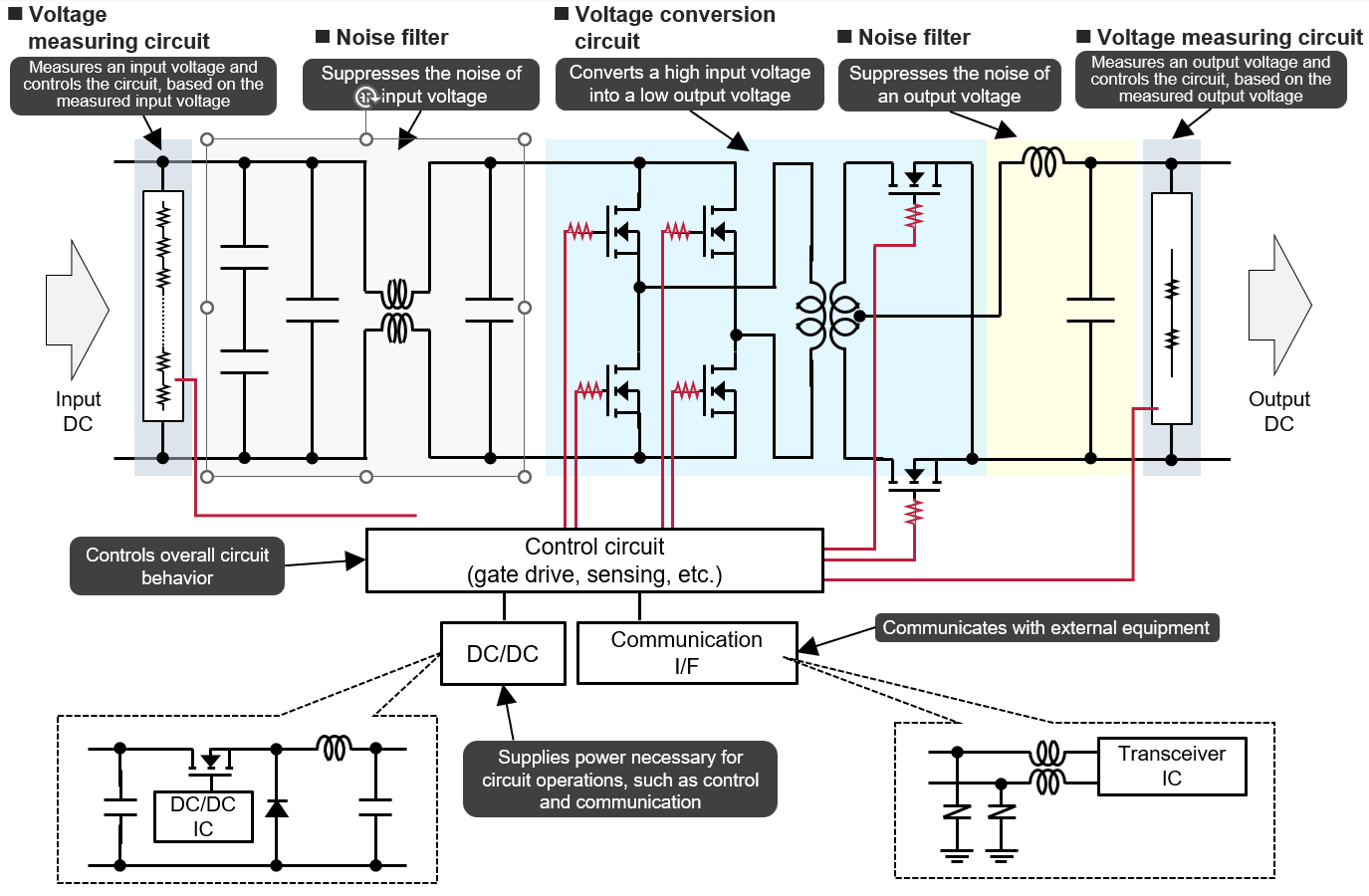

A typical DC/DC converter consists of several key functional blocks:

- Voltage Detection (Input/Output): Measures voltage levels to control conversion accuracy.

- Noise Filters: Suppress electromagnetic interference using inductors and hybrid aluminum electrolytic capacitors.

- Voltage Conversion Circuit: Uses switching elements and transformers to step down voltage.

- Control Circuit: Manages switching operations and overall system behavior.

- Communication Interface: Enables external communication via CAN or Ethernet, protected by chip varistors against ESD.

Key Components Used

- Film Capacitors: For input/output noise filtering

- Hybrid Aluminum Electrolytic Capacitors: For smoothing and noise suppression

- Automotive Power Inductors: For voltage conversion

- High-Precision Chip Resistors: For voltage measurement

- Chip Varistors: For ESD protection in communication circuits

Panasonic’s Component Solutions for DC/DC Converters

Panasonic Industry offers a wide range of high-performance components tailored for automotive DC/DC converter applications:

- Automotive Film Capacitors

- Hybrid Aluminum Electrolytic Capacitors

- Automotive Power Inductors

- High-Precision Chip Resistors

- High-Power Chip Resistors

- Chip Varistors

Conclusion

DC/DC converters are indispensable in EVs, enabling the safe and efficient operation of low-voltage systems from high-voltage sources. As EV technology continues to evolve, the demand for compact, high-output, and thermally robust converters will grow. Panasonic Industry is committed to supporting this transformation with advanced electronic components that meet the highest standards of automotive reliability.

| Component | Feature | High voltage | Large current | Low loss | Miniaturization | High heat resistance | High precision |

| Film Capacitors (Automotive, Industrial and Infrastructure Use) | High reliability |  |

|

||||

| Conductive Polymer Hybrid Aluminum Electrolytic Capacitors | Low ESR High reliability |

|

|

|

|

|

|

| Power Inductors for Automotive application | Large current, low loss High reliability |

|

|

|

|

||

| High Precision Chip Resistors Small & High Power Chip Resistors |

High precision, high resistance to heat |  |

|

|

|

|

|

| Chip Varistor | Small and light |  |