RoadTest: Review Multicomp Pro 3D Printer Filaments, PLA and PETG

Author: ischonfeld

Creation date:

Evaluation Type: Independent Products

Did you receive all parts the manufacturer stated would be included in the package?: True

What other parts do you consider comparable to this product?: This filament is comparable to other inexpensive generic filament

What were the biggest problems encountered?: "Stale" filament in the case of the Black PLA filament, poor fine line and adhesion in the case of the Blue PETG filament

Detailed Review:

This roadtest was designed to evaluate Multicomp filaments. Four different filaments were provided for testing, 2 PLA, 1 PETG and 1 ABS. In the way of a little background, I have been designing for and using FDM 3D printers for 9 years and have purchased numerous types and brands of filament over the years. After using these different brands, I am now using Prusa’s Prusament filament for almost 100% of my printing needs.

QUICK SUMMARY:

All testing was done on a Prusa XL 5 head printer. Each filament was evaluated on its own, unrelated to the others. My testing was centered on obtaining clean, precise, usable prints from each filament. The default “generic filament” settings were used as a start in all cases; minor tuning was done using printer settings on the printer as needed. Each filament was used to print one or more designs that I needed to print anyway, and also used to print the "Kickstarter FDM Test KSR" benchmark (https://github.com/kickstarter/kickstarter-autodesk-3d). The KSR benchmark tests overhangs, stringing, bridging, and fine detail. Although it is primarily used to benchmark printers, it also served well to see what each filament was capable of, knowing what the printer is capable of.

I was initially very impressed with Multicomp’s PLA MC002547 in black. It printed very well for both designed object printing and the benchmark. However, after sitting for 3 weeks, the filament cracked and became brittle. More on this below.

Multicomp’s PETG MC011473 in blue was kind of a disappointment. About half of my printing is in PETG so I was hopeful with this filament. What I encountered was a lot of stringing and inability to print fine lines. More on this below.

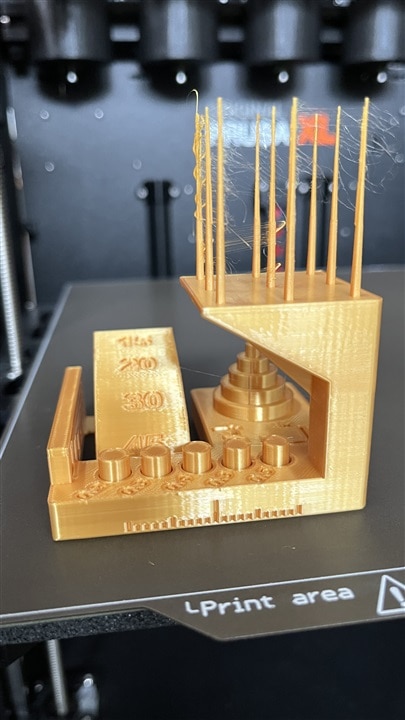

Multicomp’s PLA MP005454 in silky gold produced impressive prints. The benchmark showed a lot of stringing, but that was not an issue with an actual prints. Surface finish was beautiful. Recommended.

Multicomp’s ABS MC011440 in natural was also a winner. Once the feed rate was dialed in (had to run at 94%), this filament produced very nice prints, good surface finish and great fine detail.

UNBOXING:

PLA Black – spool is random wound in a vacuum sealed pouch. No way to reseal. Clear plastic spool. Printing temperature listed as 210-230C. This does not match the listing (temperature suggestions) for the same part number on Newark’s website. I ran 215C for the first layer, 210C for the rest.

PETG Blue – spool is somewhat precision wound in a vacuum sealed pouch. Fiberboard spool. Printing temperature listed as 230-250C. I printed at 230C for the first layer, 240C for the rest. There was an attempt to tune this to reduce stringing.

PLA Silky Gold – spool is precision wound in a vacuum sealed pouch. Black plastic spool. Printing temperature 190-220C. Date code indicates 20211224, no other spools have a date code. As with the Black above, I ran at 215C/210C.

ABS Natural – spool is random wound in a vacuum sealed pouch. Fiberboard spool. Printing temperature on the label indicates 230-270C. I printed at 255C. Picture and temp suggestions do not match Newark website.

General nitpicks:

PRINTING:

PLA Black: As mentioned above, I was originally impressed with this filament. Nice glossy finish. The benchmark showed virtually no stringing, and decent bridging. The underside of overhangs at 45 and 30 degrees were perfect, and even 20 and 15 degree overhangs were more than acceptable.

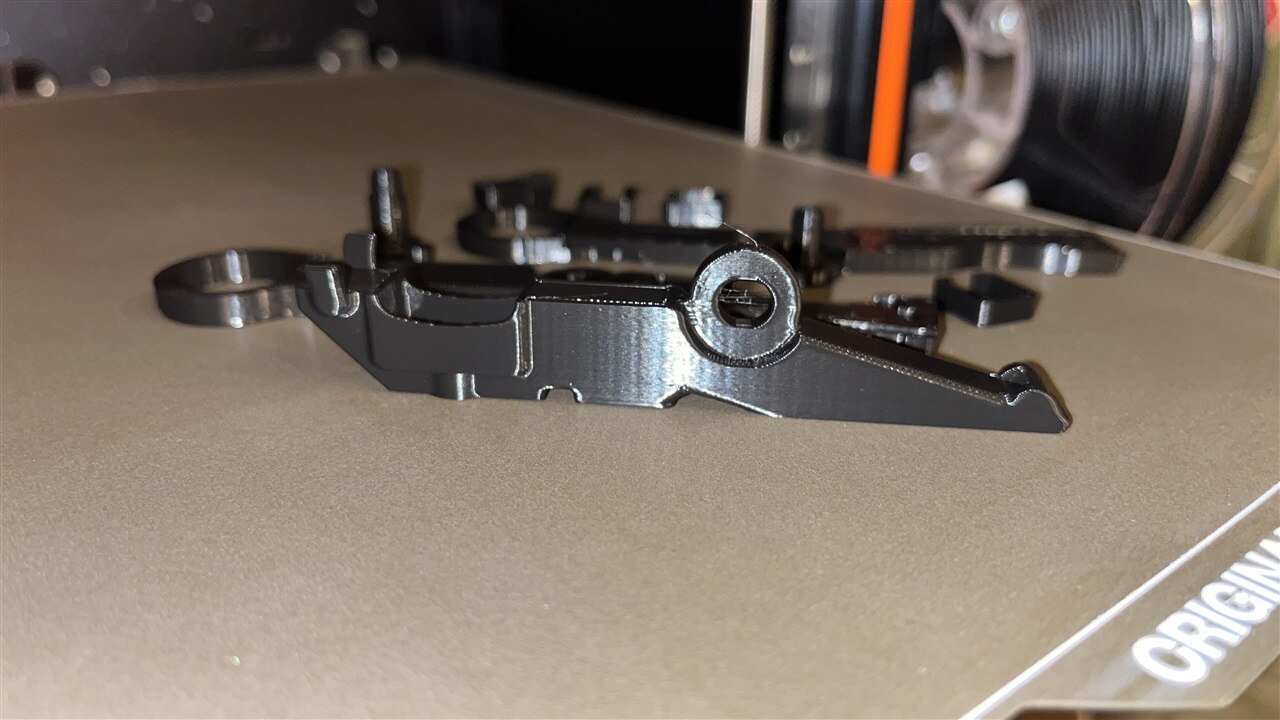

My first actual print with this filament also had no issues:

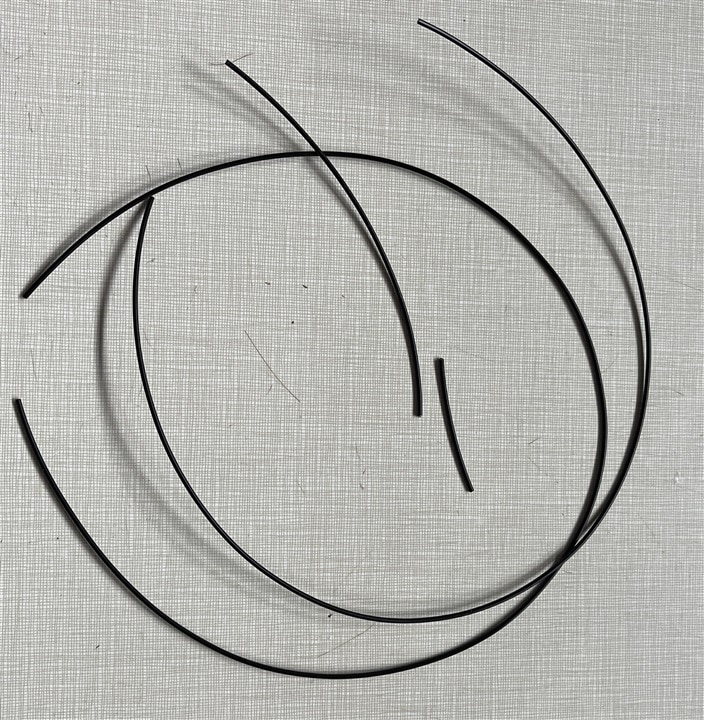

All of my testing spanned a few weeks’ time, and this filament was left on the printer (having 5 printheads lends itself to that). After about 3 weeks, I needed to swap this filament out for another spool. It was then that I noticed problems. The filament had broken where it entered the Bowden tube. And when trying to unload it, there were 3 more breaks within the tube. Filament still on the spool was brittle and easy to break. Note that this is in a temperature controlled, low humidity room. I’ve left other PLA out for months without a problem. I can only assume that perhaps this filament was old?

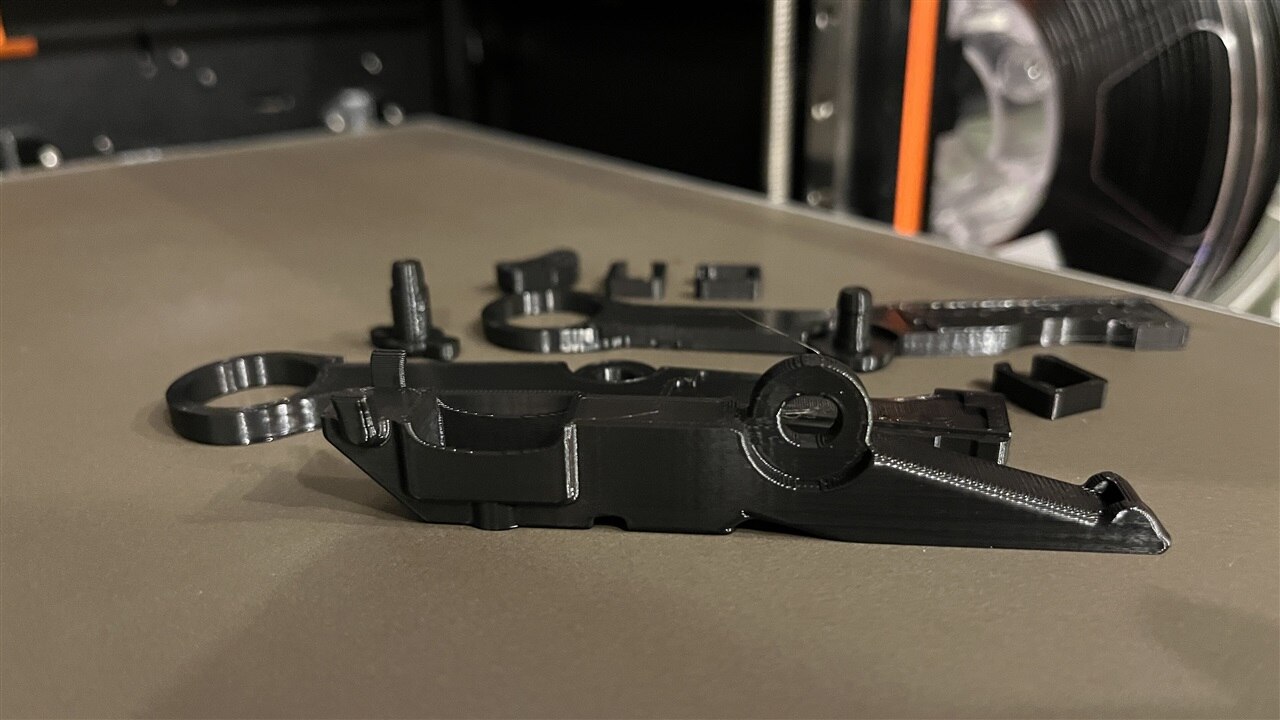

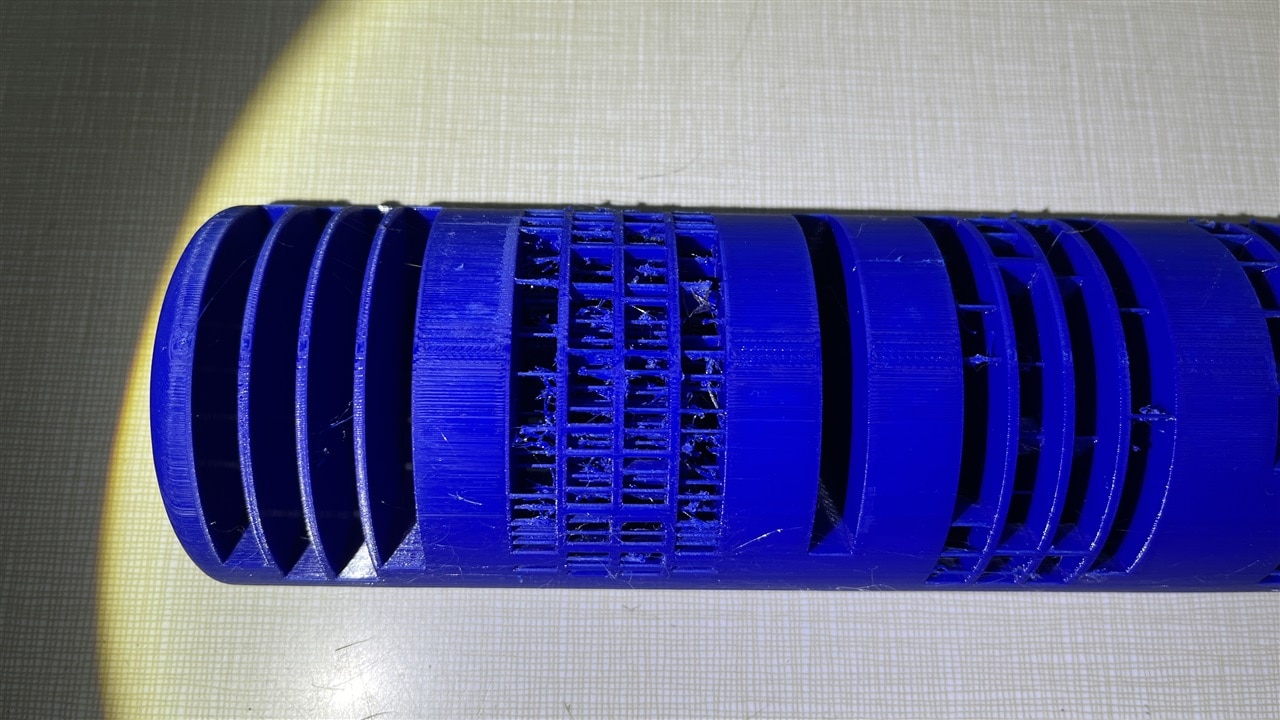

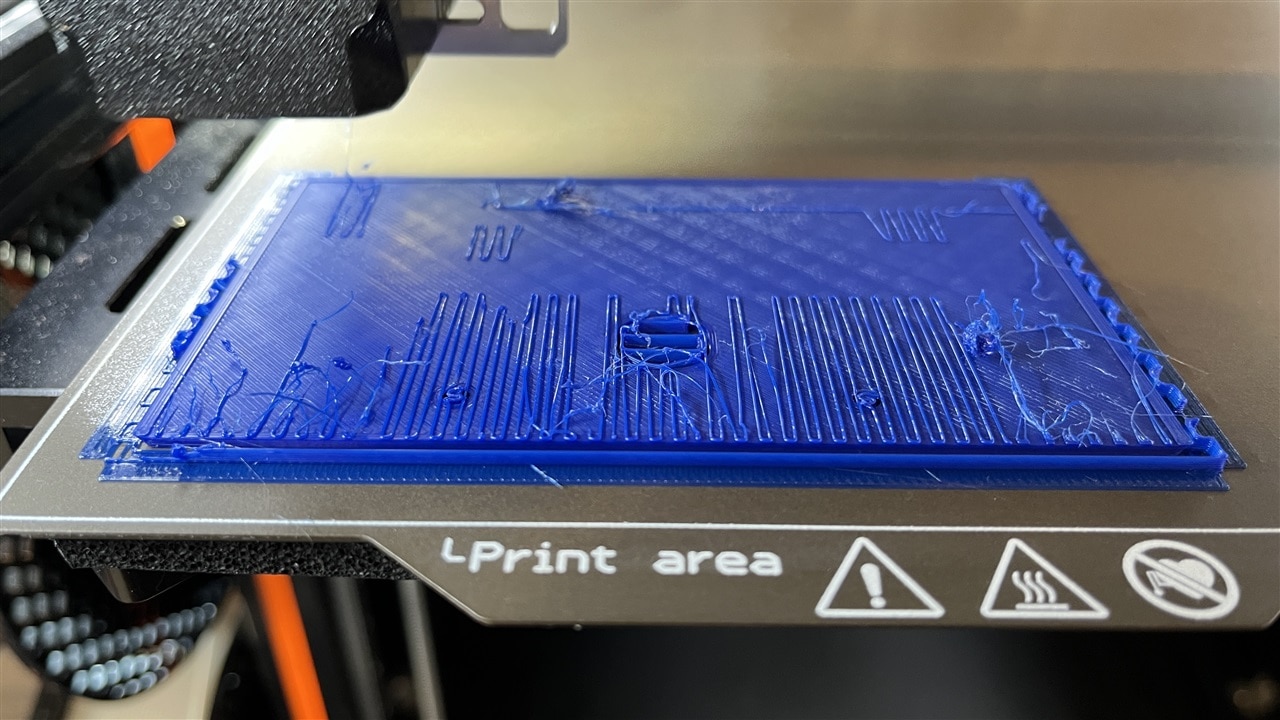

PETG Blue: The first object I printed required a significant number of very fine lines. Prior to this, I’ve printed this before successfully. The filament could not sustain fine lines, and generated a lot of stringing. During the print (several hours), I attempted to adjust the extruder temperature but could not get any improvement.

The second object I tried to print with this filament was the case for a differential thermostat. It required supports but again fine lines and interlayer adhesion (for supports) was a problem. Even trying to reorient and minimize supports didn't help.

I attempted to re-slice the design adjust temperature, etc, but I still needed to abandon the print. As shown in the picture below, surface quality even when supports did work was horrible. Left is Multicomp (abandoned print), right is Prusament, both PETG.

I printed two other items that did not require any supports nor any fine lines, and there were no issues (although some minor stringing)

I did not try to print the KSR Benchmark with this filament due to what I saw on the initial prints.

Also as an FYI, at 230C you get a glossy finish, at 220 you get a flat finish. And I adjusted the feed rate to 95% due to "blobs" of filament accumulating on the first and second layers.

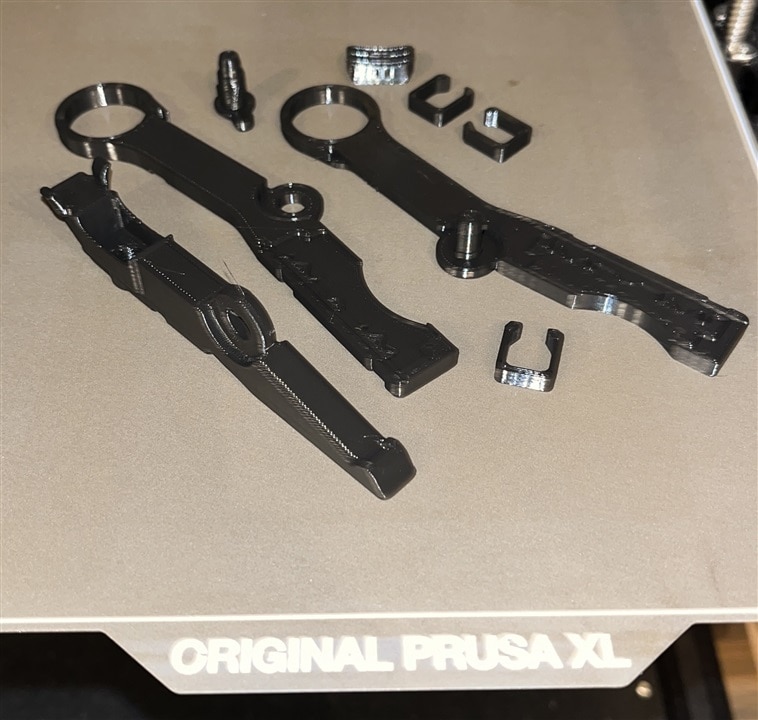

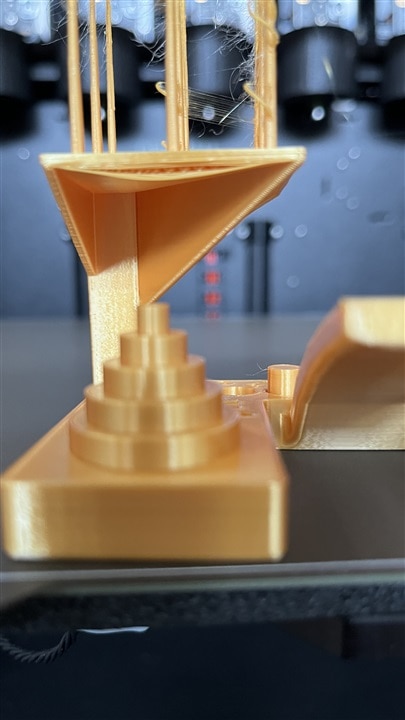

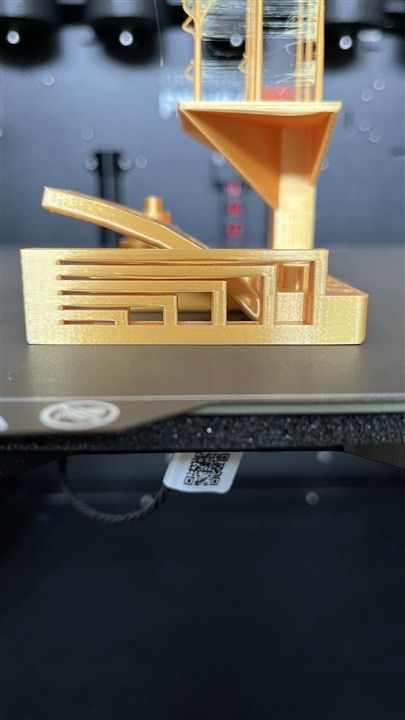

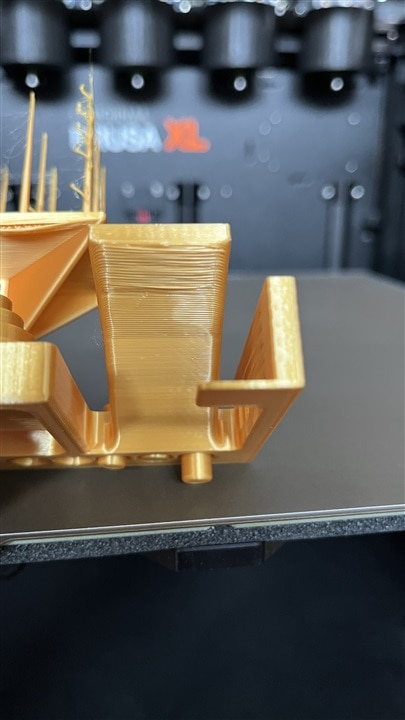

PLA Gold: This is a case where the printed object is much better than the benchmark might suggest. Very few supports were used on this print. Only the small cable guide on the base and the small circular holder had supports. The “rods” and the entire V-shaped front were printed without support. No stringing of any kind was observed.

The benchmark did show some issues. Bridging was poor and there was significant stringing. Overhangs of 45, 30 and 20 degrees were good, 15 degrees I would deem unacceptable. It is likely that some temperature tuning would rectify these issues.

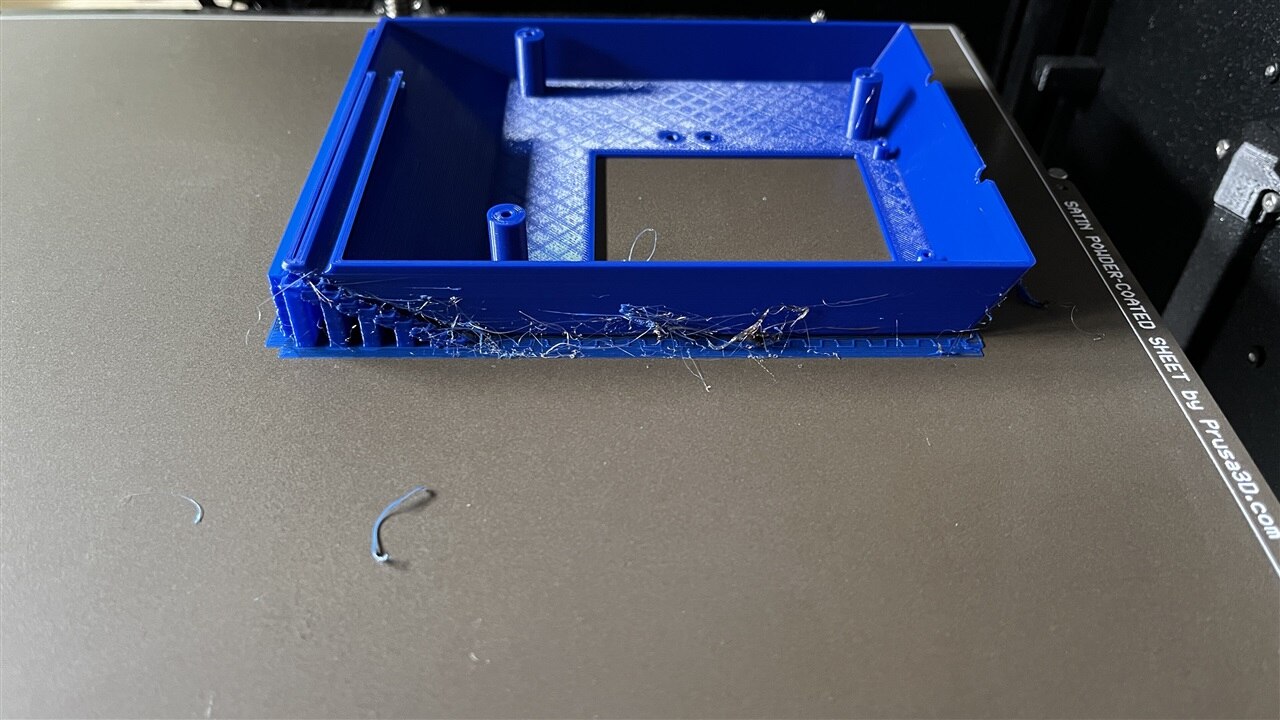

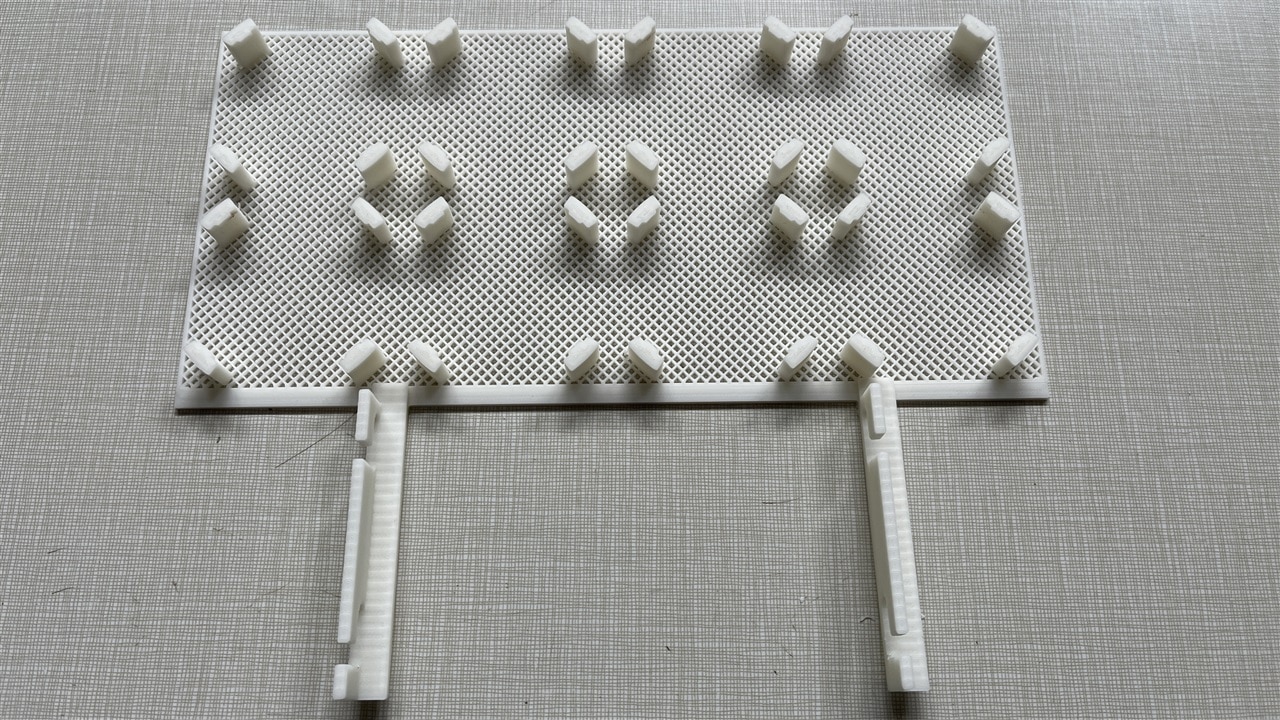

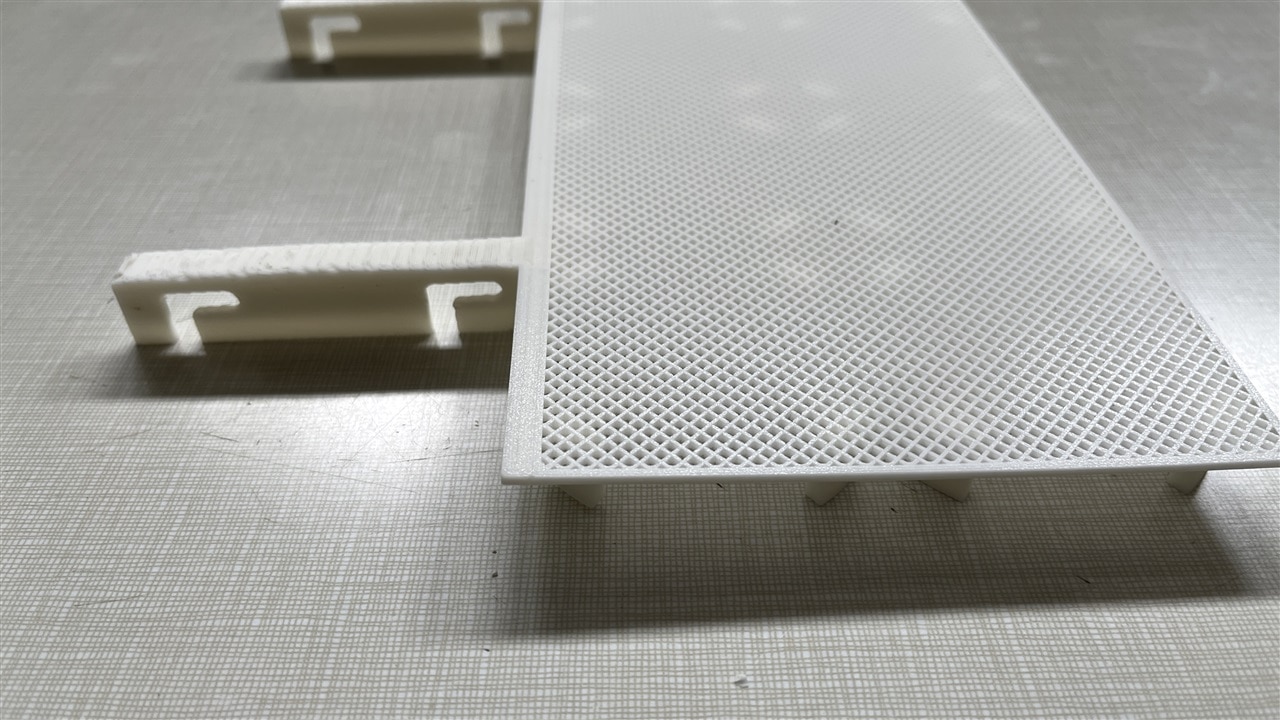

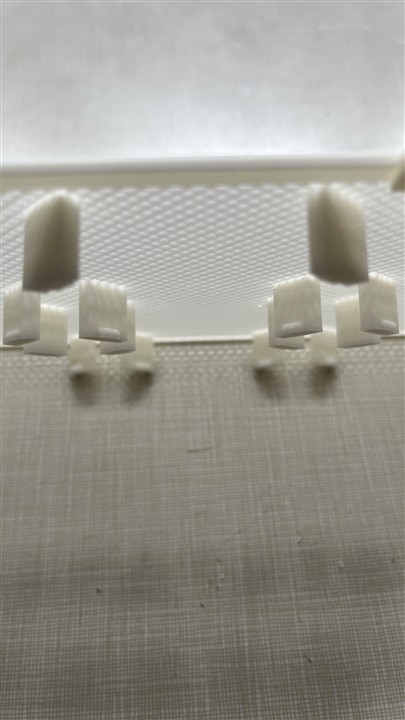

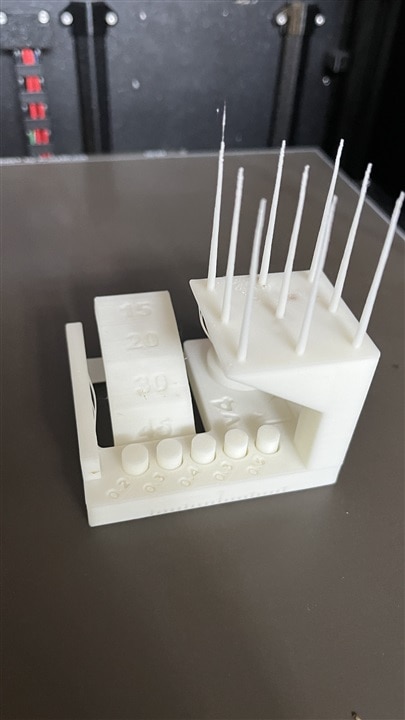

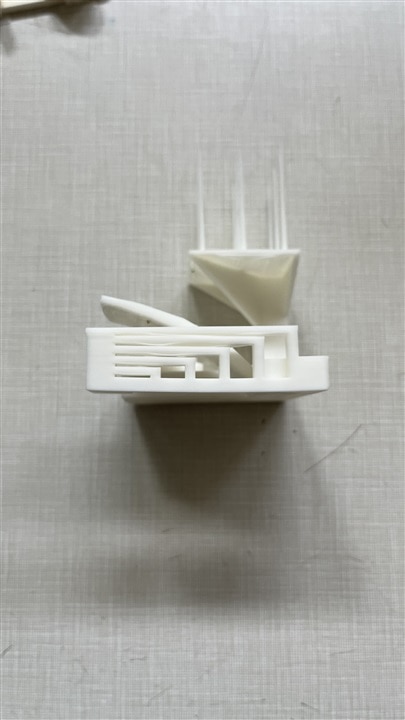

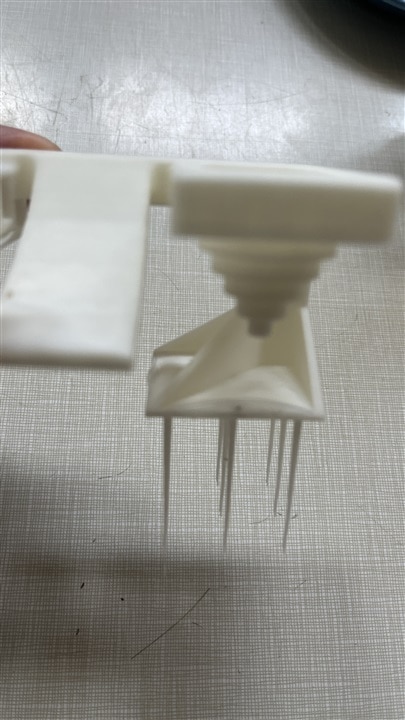

ABS Natural: This filament performed well. After a quick test, With this filament I needed to dial in the feed rate to 95%. Once established, I was able to print a fine lined mesh object with some minor supports under the legs. Picture shows the legs (left side) after supports were removed. Support material adhered to the part more than expected - I believe that a temperature adjustment (reducing it from 255C) might correct this. On the other hand, the supports for the "nub" extensions shown in picture 3 were easily removed and left no visible debris.

The KSR benchmark showed virtually zero stringing. However bridging was poor. Layer lines were virtually invisible. I believe that a lower temperature would help with bridging but likely increase the visibility of layer lines.

Learn more about Newark's information on Multicomp Pro's 3D Printer Filaments

Top Comments

The breaking syndrome of PLA that is left in a stressed position is very common. Some spools are less prone than others, but pretty much all PLA will fracture easily after being held in a stressed condition…