Compact fans play a critical role in maintaining the performance and life of the equipment in both domestic and industrial applications. Correct fan selection for a particular application is a complex assignment. This comprehensive guide takes you through the basics of compact fans and helps you select the right fan for any application.

What are Compact Fans?

As the name implies, compact fans are smaller in size compared to larger, industrial-grade fans. They are used to move high volumes of air from spaces where installing large fans is just not possible. Compact fans are energy-efficient, available in various voltage and frequency ranges, and can be integrated into the existing device logic.

What are the Benefits of Compact Fans?

Compact fans are highly efficient and are capable of providing high output despite their compact design, making them suitable for many applications. Compact fans are lightweight, which streamlines installation. Compact fans can tolerate direct UV radiation, contact with acids and salts, humidity, and condensation. They can also be used in applications where they are routinely subjected to shock and vibration, enabling compact fans to be used in a variety of extreme environments. In addition, compact fans can be intelligently connected to adapt to the device logic or existing control systems.

Types of Compact Fans

Compact fans can be differentiated based on desired airflow, power consumption, form factor, and applications.

Some common types of compact fans include:

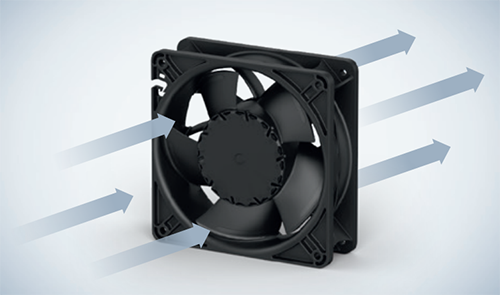

Axial Compact Fans are frequently used in exhaust applications with small airborne particulate sizes, such as dust streams, smoke, and steam. They are also suitable for ventilation applications that require reverse airflow. Axial compact fans use an impeller to produce airflow towards the direction of the axis of rotation, with the blades forcing air linearly to the shaft. They deliver air with the lowest power consumption at zero static pressure. Overall, the axial design offers high air volume and low pressure, which makes them ideal for evenly cooling equipment and spaces in a defined area.

Figure 1: Axial compact fan (Source: ebm-papst)

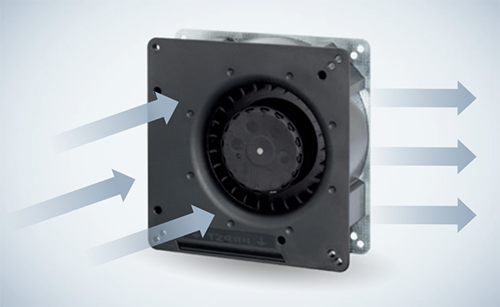

Centrifugal compact fans are favored when the cooling airflow must be deflected by 90° or when a higher pressure increase is needed. These fans typically require more power to operate than axial fans. Figure 2 depicts the air flow of a centrifugal compact fan.

Figure 2: Centrifugal compact fan

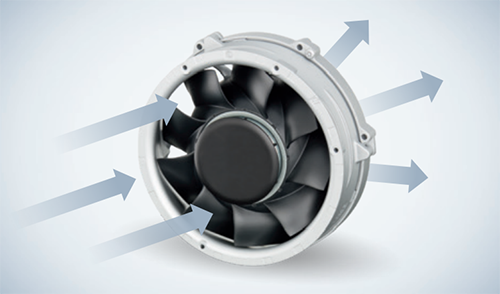

Diagonal compact fans are particularly suitable for intensive cooling applications with a high component concentration, like control cabinets. They combine the favorable properties of axial and centrifugal fans. In diagonal compact fans, air draw is axial but with a diagonal outflow. The impeller and housings are conical, resulting in greater intake air compression. The advantage of such a configuration is that the airflow is similar to an axial fan, but with a greater pressure increase and lower operating noise.

Figure 3: Diagonal compact fan

|

What’s the difference between an impeller and a propeller? On the surface, an impeller and a propeller are not all that different. They do, however, serve different functions. One key difference lies in the direction of flow. A propeller converts rotational motion into linear thrust, usually in an open system. The resulting force pushes air and fluids away, often moving the system in the process. An impeller, on the other hand, uses the same rotational motion to increase pressure within a closed system. The increase in pressure creates a sucking force, pulling air or liquid into the system and increasing flow throughout. In this case, compact fans use impellers. |

How Do You Select a Compact Fan?

There are several parameters to consider when selecting a compact fan:

Dissipated energy: A large percentage of the energy consumed by electronic devices is converted to heat. This heat must be removed and selecting the correct type of fan is necessary to help dissipate such unwanted energy. The electrical power consumption of the unit to be cooled often represents a suitable value for this purpose.

Admissible temperature increase: The fan's required airflow is determined by the dissipated energy and the admissible heating (ΔT) of the cooling airflow (from entry to exit of the device to be cooled). The maximum allowed admissible ΔT is based on the temperature sensitivity of the individual parts of the device. An ΔT of 5K means that the average cooling airflow leaving the device may be only 5°C warmer than the ambient temperature, requiring a great deal of airflow. A lower airflow rate is sufficient if a higher temperature difference (e.g., ΔT = 20K) can be tolerated.

Noise: A fan's noise results from the combination of fan type, airflow rate, and pressure. A comparatively high noise level is a sign of inefficient operation of a specific fan type. If high fan noise levels are unavoidable, then methods of attenuating the acoustic energy should be explored.

Rotational Speed. The rotational speed of a fan directly affects its performance. Fans that produce high airflow at relatively low speeds (for example, centrifugal fans) require a reasonably accurate estimate of the pressure demand and system airflow. Improper calculation of fan rotational speed due to uncertain system requirements can cause under-performance or excessive airflow and pressure.

Airflow Requirements: Airflow impedance, also called back pressure, is an important consideration when selecting a compact fan. A fan unable to complement airflow requirements for a specific back pressure may suffer extensive damage. For example, if the calculated airflow requirement for zero back pressure is 50 CFM, the fan must be selected with 75-100 CFM airflow for operating back pressure.

Temperature Range: In high-temperature environments, the fan materials can lose mechanical strength. This can be avoided by selecting alloys to provide the required mechanical properties at the desired operating temperatures.

Efficiency: The efficiency of a compact fan is the ratio of the power imparted to the airstream to the power delivered by the motor. An essential aspect of a fan performance curve is the its efficiency point, where a fan operates most cost-effectively in terms of both maintenance considerations and energy efficiency.

Challenges of Compact Fans

There are various challenges when using compact fans, including:

Pressure drops: Compact fans may struggle to generate high static pressure, which is essential for applications that require air to be pushed through obstacles or ductwork. Fans typically combat this loss of back pressure by generating high airflow rates. In severe cases, compact fan motors may overload and automatically shut down (if protected by a thermal switch) or even suffer permanent failure.

Noise: Improper selection of compact fans or fans operating at higher speeds than necessary can create problematic levels of noise. For example, patients may experience a reduced quality of care if the cooling technology in medical electronics emits a high audible noise. Another example would be a noisy refrigerated display case in a supermarket.

Dust and Contaminants: Compact fans are susceptible to dust and contaminants. The level of contamination is related to the velocity of airflow and blades’ angle of attack, which can significantly affect fan performance over time. Compact fans should thus have regular cleaning and maintenance.

Vibration and Balancing: The bearings in the compact fan assembly wear over time. Such degradation can create vibrations, mechanical faults, and noise issues. Bearings should be cleaned and lubricated regularly to prevent unplanned downtimes.

Electrical Damage: Frequent start-ups of large loads apply a significant amount of stress to the fan's motor windings. The in-rush current and the starting current for motors create voltage sags in the electrical system and cause the motor to run hot for several minutes. Soft starters keep the motor temperature low, extending the fan motor life. A soft starter gradually ramps up the voltage to the fan motor, limiting the in-rush and starting current.

What are the Primary Applications of Compact Fans?

Compact fans are used in a wide variety of applications, including control cabinets for IT telecommunications, routers, base station servers, and power supplies. Medical electronics use compact fans for cooling oxygen concentrators, MRI scanners, and sleep therapy devices. They are also used in industrial automation. Compact fans are present in printing machines, welding machines, solar inverters, variable frequency drives, battery cooling systems, and uninterruptible power supplies (UPS). They are also used in refrigerated display cases, heat pump dryers, and kitchen appliances. In the transportation sector, they are used in construction equipment, passenger and commercial vehicles, and locomotives.

Are Compact Fans Energy Efficient?

Compact fans are quiet and highly efficient energy-saving fans that provide high output in a small form factor. They are available for most voltage levels and can be intelligently networked with the equipment logic.

How do Axial, Centrifugal, and Diagonal Compact Fans Compare?

| Parameters | Axial | Centrifugal | Diagonal |

|---|---|---|---|

| Airflow Profile | Air flows through the fan blades in parallel with the axis of rotation | Air is discharged at an angle of 90° (perpendicular) to the air intake. | Air is spread diagonally on discharge |

| Voltage | 5–75 VDC, 11–440 VAC | 6-72 VDC, 103-264 VAC | 9-72 VDC |

| Airflow Rate | Up to 1,220 m3/h | Up to 1600 m3/h | Up to 1,100 m3/h |

| Power Consumption | 0.1–275 W | 1-190 W | 19-360 W |

| Application | Suitable for applications where a reasonably small pressure rise (up to 1500 Pa) and large flow rates are required | Suitable for applications with lower flow rates requiring higher pressure (up to 5,200 Pa) | Suitable for applications where a high airflow rate with a relatively high-pressure increase (up to 1,500 Pa) is required |

Advantages of Compact Fans

Some of the characteristics that make compact fans attractive include:

Low Noise Level: Compact fans produce consistently low noise levels due to their aerodynamically optimized design and high mechanical precision.

Durability: The advanced bearing technology of compact fans can sustain extreme thermal stress and adverse application conditions, making them durable and smooth.

Efficiency: Compact fans can be controlled intelligently, enabling them to be energy efficient, and low maintenance, with a longer service life and reduced sound pollution.

Form Factor: Compact fans have aerodynamically optimized fan impellers and fan housings. They generate a high output without compromising air performance or efficiency despite being of compact design.

How do you Choose a Specific Fan for Cooling a Particular System?

Choosing a specific fan for cooling a particular system involves the following steps:

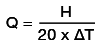

To choose a specific fan for cooling a particular system, first determine the required internal temperature of the system, as well as the amount of heat generated internally. The required airflow can then be calculated using the following equation:

where Q = Airflow(m3/min), H = Total heat generation(W) and ΔT = Temperature rise value(°C).

The airflow of the cooling fan mounted in the system can be obtained using the airflow-static pressure characteristics curve and the pressure losses of the system. Since it is difficult to calculate the system pressure loss, a fan with 1.5 to 2 times the required airflow is generally recommended.

Multiple smaller fans often operate in tandem as FanGrids for superior performance in modern ventilation technology. This arrangement has a considerable advantages over large individual fans. Better heat transfer and more efficient air filtering are possible when there is uniform flow through the filters or heat exchangers. In addition, several small fans typically require less space, reducing system costs. The redundant design of a FanGrid ensures the best possible compensation for the loss of air performance.

FanScout is a free software package from ebm-papst that guides you through the fan selection process.

What is the Difference Between the S-Panther and AxiForce Series of Compact Fans?

Two modern compact fans from ebm-papst are the S-Panther and the AxiForce series. The differences between the two include:

| Parameters | S-Panther | AxiForce |

|---|---|---|

| Technology | S-Panther features a new impeller design with innovative winglets, a turbulator, and a unique strut design | Developed for applications with high back pressure (up to 1,400 Pa), the AxiForce series features a steeper characteristic curve, enabling greater airflow despite higher back pressures and achieving considerable performance increases. |

| Efficiency | S-Panther is up to 9% more efficient than its comparable predecessor (S-Force). The airflow of the high-end solution is between 970 m³/h and 1030 m³/h. With the more economical solution, the airflow is between 540 m³/h and 760 m³/h. | AxiForce 80 increases efficiency by 42% over its predecessor at an operating point of 108 m³/h at 285 Pa back pressure. |

| Noise Emission | Noise levels are up to 9 dB(A) lower compared to its predecessor | Noise levels are approximately 7 dB(A) lower when compared to its predecessor. |

| Ingress Protection | IP54 rated - protected against contamination from limited amounts of dust and other particles. Protects against moisture and salt spray | IP68 rated – dustproof and protected against powerful water jets. This variant can also pass a 30-day salt spray test. |

| Application | Well-suited for use in variable frequency drives, welding machines, solar inverters, and IT and telecommunications applications. | Well-suited for cooling automation equipment such as variable frequency drives and robot controllers, LED displays, power modules for 5G mobile network infrastructure, electronics in video streaming servers, or data center equipment. |

Frequently Asked Questions

In partnership with

Which fan is best for a small room?

Compact fans are designed for the cooling of equipment, and not typically used for the ventilation of a small room.

What are small fans called?

Small fans are often referred to as compact fans.

Which is the smallest fan?

Axial fans are smaller and lighter than centrifugal and diagonal fans.

What is an electronic commutated fan?

Electronically Commutated (EC) is a fan with a brushless, permanent magnet DC motor with onboard electronics available for controlling a fan rotor. This allows for variable speed operation and the optimization of airflow based on the specific requirements of the application. These fans are designed to be more energy-efficient and quieter compared to traditional AC fans or motors.

What is a micro fan?

Micro fans are fans with a very small form factor (as small as 8mm) designed for cooling in tight or limited spaces. These fans are highly energy efficient and have a long operating life.

What is the smallest CPU fan size?

The smallest CPU fan size commercially available is around 40 mm to 60 mm in diameter.

What are the quietest fans for a PC?

Typically, axial fans are the quietest fans for a PC, however, there are many compact fans that are specifically designed for quiet operation. In addition, software can be used to control fan speeds, in order to optimizing the cooling for a balance between noise and performance.

Can You Use an exterior cooling fan on a desktop computer?

Depending on placement, external fans are able pass cooler outside air into the desktop PC to assist with air circulation and cooling. However, an internal fan will cool the inside of a desktop computer more efficiently than an external one.

What is the difference between a regular fan and an industrial fan?

An industrial fan has a higher operating speed and generates high volume and low pressure, whereas a regular fan generates high pressure and low volume.

What size are industrial fans?

Industrial fans are available from 56 inches to 24 feet in diameter.

Compact Fans from ebm-papst

ebm‑papst provides a wide range of compact fans and associated accessories tailored to meet various applications.