What is a Resettable Fuse?

A resettable fuse is a device that protects electronic circuits from damage caused by overcurrent conditions, overloads, overheating, or short circuits. There are two types of resettable fuses: traditional radial lead and SMD chip packages. Resettable fuses have a Positive Temperature Coefficient (PTC), which means that a rise in temperature is followed by an increase in resistance. When a rise in temperature occurs due to an overcurrent or similar fault state, resistance in the fuse increases, reducing the current. Once the fault is rectified, the PTC’s core cools and contracts, allowing the current to flow normally. This ability to reset differentiates a resettable fuse from a regular fuse, which must be replaced after a fault condition.

How do PTCs work?

Internal structure of the resettable polymer PTC

A PPTC device is made of a polymer material containing a conductive filler bonded between two conductive plates. Figure 1 depicts a typical conductive chain and thermal expansion model, which illustrates the physical mechanics behind the PPTC. At normal temperatures, conductive particles in the polymer composite create a plethora conductive paths that allow current to flow through the fuse without interruption. At high temperatures, the phase change of polymer becomes amorphous from its crystalline state, resulting in a volume expansion that breaks most of the conductive paths. This leads to a sharp, nonlinear increase in the device's resistance, which serves to protect circuit components by reducing the amount of current flowing through them. Once the fault current or high ambient temperature is removed and/or the power is switched off, the polymer begins to cool and resume its original state. The device is ultimately restored to a low-resistance state.

Figure 1: Thermal expansion model and internal structure of a polymer PTC

Source: Failure Causes of a Polymer Resettable Circuit Protection Device, Journal of Electronic Materials

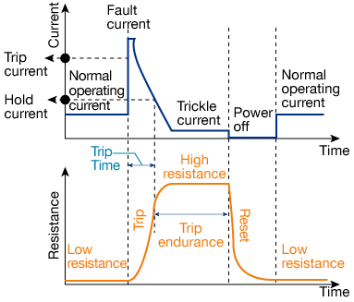

Resistance and current flow in a PPTC device

The temperature-sensitive PPTC device reaches a “tripped” state when the device in the presence of excessive heat. The device now has a much higher resistance. The amount of electricity required to trip the PPTC varies depending on the device, ranging from tiny (20mA) to large (100A). A tripped device allows minimal flow of electricity, which translates to minimum production of heat. Once power is removed, the slowly PPTC cools, returning to its normal state, and allowing electricity to flow. Figure 2 illustrates the process.

Figure 2: Operational process of PTC resettable fuse

Source: Failure Causes of a Polymer Resettable Circuit Protection Device, Journal of Electronic Materials

Is a polymer PTC resettable fuse a semiconductor?

No. PPTC fuses operate differently, unlike the charge carriers of a semiconductor.

What is the Reliability of PTC Resettable Fuses?

Resettable fuses have seen a dramatic rate of adoption in recent years. Their use in electronics hardware, especially in the automotive space, will continue. PTC fuses improve the reliability of electronics due to their unique characteristic of self-resetting during a recovery period after it has tripped (open high resistance) due to a fault state.

What are the different types of resettable fuses?

There are two main types of resettable fuses: Ceramic PTC and Polymeric PTC, each with different features, making them suitable for different application. The selection of a particular type of fuse depends on the requirement of the application. Both types of PTC resettable fuses exhibit a PTC of resistance.

Ceramic PTC fuses are typically used in high-current applications. Ceramic PTC fuses are constructed of ceramic material and have high-current capacity with low resistance values. Polymeric PTCs are mainly used in low-current applications. Polymeric fuses are typically smaller and have faster response times.

Resettable fuses are available in different form factors and mounting options, including battery strap, radial leaded, and surface mount.

Axial Lead Battery Strap PTCs

Axial Lead Battery Strap PTCs are used in rechargeable and lithium-ion battery packs to provide overcurrent protection. The 0ZSC series from Belfuse can manage any current from 1.2 to 4.2A and can work with any voltage from 15 to 30 VDC.

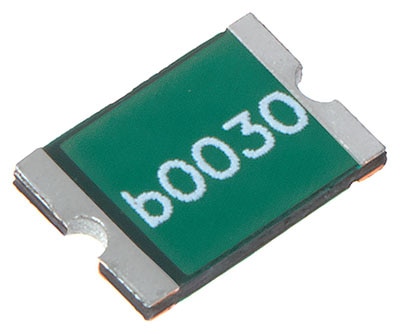

Surface mount PTC

OXCG Series Surface-mount PPTC

Buy now

Surface mount resettable fuses are used in consumer electronics and other applications where space is at a premium. They are mounted directly on a circuit board without holes being drilled into the board.

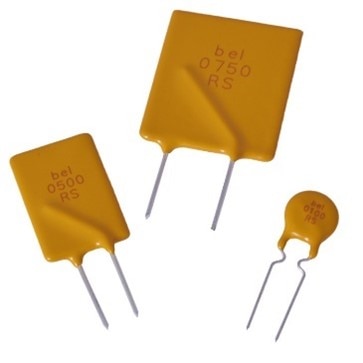

Radial Leaded PTC

0ZRS Series Radial-leaded PPTC

Buy now

Radial-leaded PTCs have leads extending from the device's body in a radial pattern. They are available in a variety of sizes and resistance values.

What are the specifications of a resettable fuse?

- Holding Current: the maximum amount of current a resettable fuse can tolerate before tripping and transitioning from a low-resistance state to a high-resistance state. The fuse’s holding current higher than the maximum amount of electricity in a circuit, so that it doesn’t trip during normal operation.

- Trip Current: the amount of current that will trip the fuse and open the circuit. Resettable fuses have a higher trip current than traditional fuses, and they are designed to trip quickly in response to overcurrent conditions. The trip current generally surpasses the holding current.

- Rated Voltage: the maximum voltage a fuse can safely operate without breaking down. The selected fuse's voltage rating must match or exceed the circuit voltage being used.

- Maximum Current: the largest amount of electricity that can pass through the fuse above which would cause it to overheat, possibly causing damage. The maximum current rating is typically specified by the thermistor manufacturer and is based on the thermistor's size, materials, and design.

- Max Time to Trip (MTT): the maximum amount of time it takes for the device to switch from a low-resistance state to a high-resistance state when a fault current occurs. The time-to-trip of a PPTC device is defined as the time required to trip the device starting at the onset of a fault current. The time is dependent on the magnitude and duration of the fault current and the ambient temperature.

- Typical Power: the amount of power typically dissipated by the fuse when in tripped state, in a 23°C still air environment.

What are resettable fuses made of?

Resettable fuses are made from a responsive conductive polymer that is thermally responsive and conducts electricity under normal conditions. Under overcurrent conditions, however, the polymer resists current flow. The polymer is blended with other materials, such as polyethylene, polycarbonate, and carbon black to offer a correct balance of thermal, mechanical, and electrical properties.

Where are resettable fuses used?

PPTC devices are commonly used in a wide range of electronic and electrical applications where protection against overcurrent conditions is required. Some common applications of resettable fuses include consumer electronics, power supplies, telecom equipment, and industrial control systems. In addition to these applications, resettable fuses are also used in various other automotive systems, such as power distribution units, starter motors, and battery management systems, to provide protection against overcurrent conditions.

What is the difference between a resettable fuse and a conventional fuse?

Both PPTCs and fuses do the same job: protecting electronic circuits from overcurrent-related problems. The difference is that fuses must be replaced after they are tripped, while PPTCs are able to reset themselves. PPTCs can handle spurts of overcurrent without needing replacement.

Both PPTCs and fuses react to excessive current flow by generating heat, but they do so in different ways. Fuses melt open, completely interrupting the current flow, while PPTCs limit the current flow by changing from a low to high resistance state as the temperature rises. In short, fuses are preferred if it is important to stop the flow of current to protect the equipment entirely. On the other hand, PPTCs are often used in situations where overcurrent events are expected to occur frequently, and maintaining constant system uptime with low service costs is important. They are also useful in remote or hard-to-reach locations where replacing a fuse would be challenging.

Frequently Asked Questions (FAQ)

What’s the difference between a resettable fuse and a circuit breaker

Both circuit breakers and resettable fuses keep electrical circuits safe. A circuit breaker is an electromechanical device that is designed to "trip" or open the contacts when the current exceeds a rated value, stopping the flow of electricity and preventing damage to the electrical equipment or the wiring. After a circuit breaker has tripped, it can be reset via switch. Circuit breakers are an essential component of any electrical distribution system. Resettable fuses, or PPTCs, perform a similar function, “tripping” if the current exceeds rated value. The difference is that resettable fuses automatically reset when there is no longer an overcurrent condition. When a circuit breaker trips, the current is cut off completely, while a resettable fuse may still allow a small current to pass.

What are the different types of resettable fuses?

Two types of resettable fuses are Polymeric PTC and Ceramic PTC. Resettable fuses can also be differentiated by form factor.

Do you need to derate resettable fuses?

Derating the resettable fuse means selecting a device with a higher current rating than the application requires. Temperature can impact the reliable operation of a resettable fuse and may require derating. Refer to the fuse manufacturer’s specifications for more information on derating.

Do resettable fuses wear out?

Repeated cycles of tripping and resetting can cause the PPTC fuse to experience thermal stress, which can degrade its polymer matrix. It is also important to regularly inspect and replace PPTC fuses that have undergone multiple trip-reset cycles.

What does a resettable fuse do?

Resettable fuses protect electronic circuits from overvoltage or overcurrent events. It is a passive safety device. Heat is generated when the current flowing through the fuse exceeds the rated value, causing the device to expand. This increases its resistance, reducing the current flowing through the fuse.

What are the disadvantages of resettable fuses?

- PPTC fuses have a higher resistance when compared to traditional fuses.

- PPTC fuses have a slower response time compared to traditional fuses, which can delay the protection of the circuit and potentially cause damage.

- PPTC fuses have limitations in terms of maximum voltage and operating temperature, restricting their use in certain applications.

- Repeated cycling of the PPTC fuse can cause it to degrade over time, reducing its reliability and lifespan.

Are resettable fuses safe?

Resettable fuses are safe when used appropriately and within their rated specifications.

Do resettable fuses have polarity?

Resettable fuses do not have polarity.

How do I know if my resettable fuse is bad?

A resettable fuse that has failed can be identified through various methods, including resistance and current measurement, visual inspection, and circuit malfunction. The method will depend on the fuse being used and the circuit.

What is the range of a resettable fuse?

The operating temperature range of resettable fuse is generally between -40ºC to +85ºC.

What is the difference between PPTC and fuse?

Fuses and PPTCs are both overcurrent protection devices. A fuse completely stops the flow of current during an overcurrent event, while a PPTC reduces the current to safe levels. Additionally, a fuse must be replaced after tripping; a PPTC automatically resets itself.

What is the rating of PPTC fuse?

The specifications of a PPTC fuse contain several ratings, including hold current, trip current, voltage and power. The rating of a PPTC fuse is critical to ensure that it provides the appropriate level of protection to the circuit it is connected to. It is important to carefully consider the electrical requirements of the circuit and select a PPTC device with appropriate ratings for the specific application.

How does a PPTC fuse work?

At normal temperatures, conductive particles in the polymer PTC create many conductive paths.

During normal operating conditions, a PPTC has low resistance and current is allowed to flow. When a high current is passed through the fuse, the temperature rises above the device's switching temperature. As a result, the polymer undergoes a phase change from a crystalline to an amorphous state, resulting in a nonlinear increase in device resistance. This breaks the circuit path, providing circuit protection.

What does PTC stand for in fuses?

PTC stands for Positive Temperature Coefficient.