I came across this lovely term on Twitter the other day for tablet and laptop battery packs that had seen better days (usually when continuously powered/charged). It's #spicy pillow. LOL.

https://twitter.com/hashtag/spicypillow?lang=en

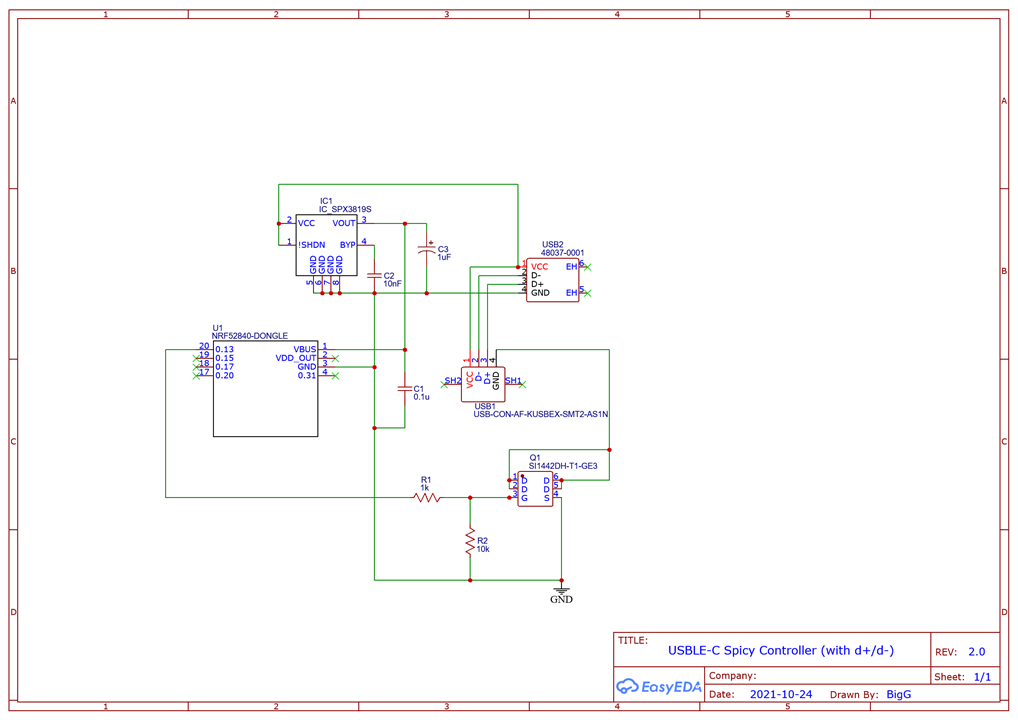

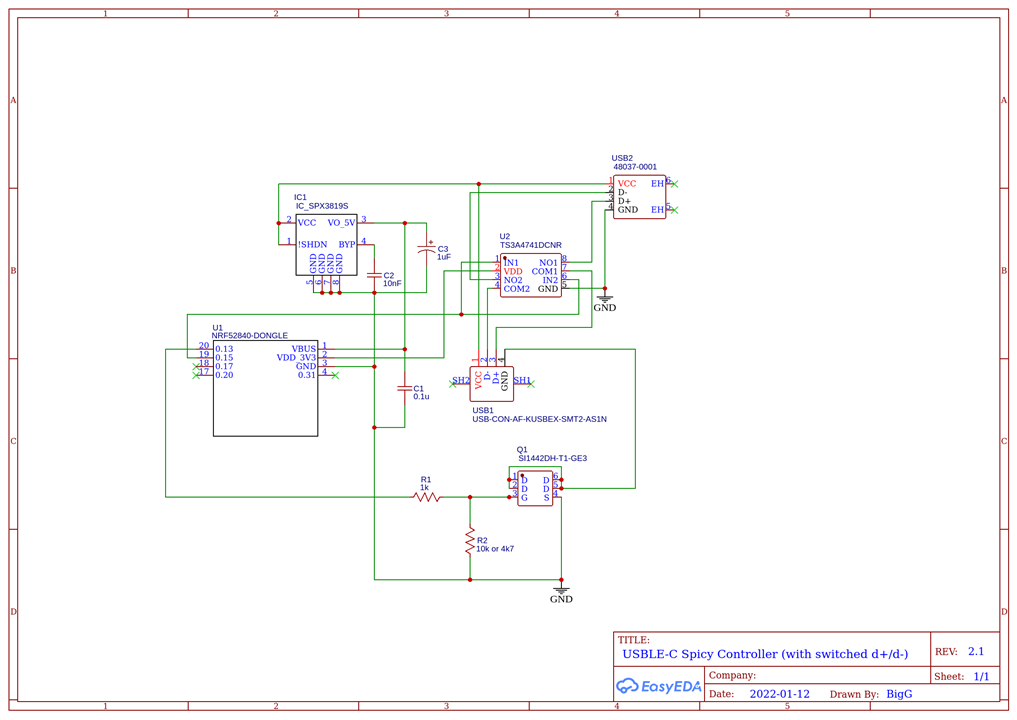

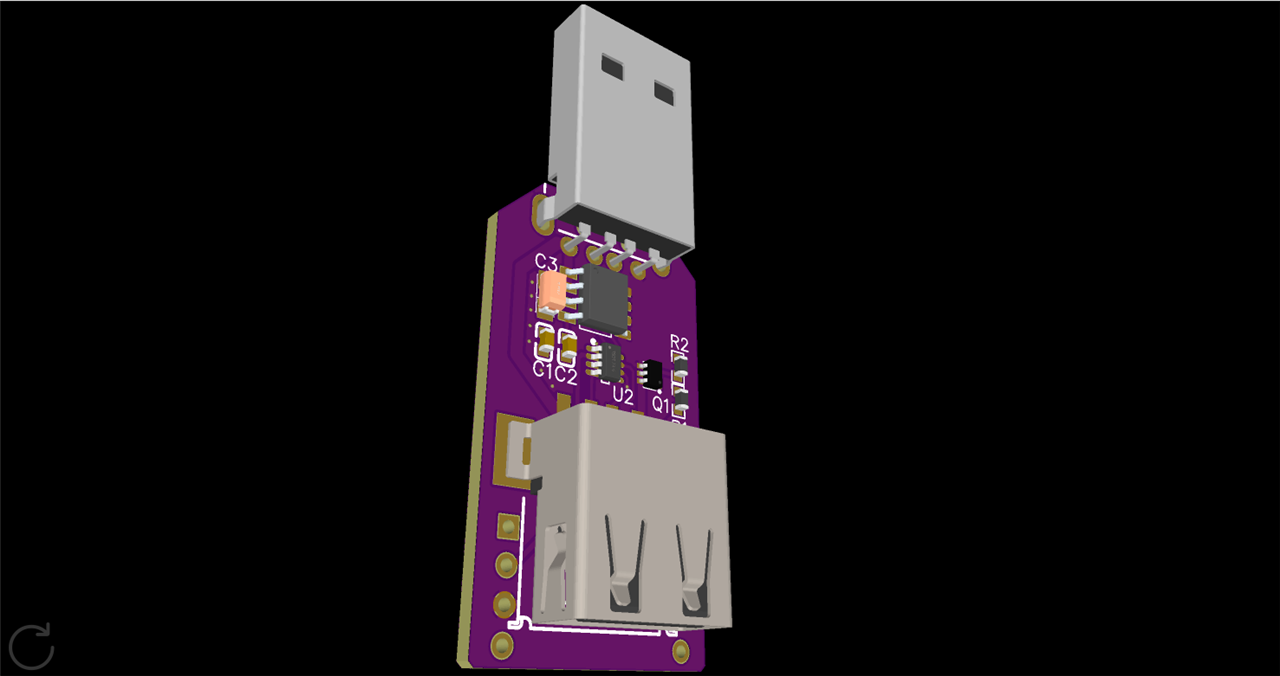

Anyway, this reminded me of a little project I had in mind (as shown in schema below).

As a electronics novice, this appears to be a borderline case as I know that transistors tend to work well for mA switches while MOSFETs tend to be targeted at higher voltages (and say +3A current).

So now struggling to choose a suitable component - I'm particularly interested at the 1.5A option as that tends to be the limit for many usb charger adapters:

Having done some prelim research it looks like FET's are the way to go but when working through my design criteria I'm quickly getting bogged down in the detail... In this case I'm not coming up with options as I can see that I need to minimise my resistance losses to reduce voltage drop etc... I'm also looking for a low cost <1$ SMD option.

Hence I thought to open this little design challenge to the members as I had to chuckle at aGough Lui status update I found when doing my e14 search...

So, any old favourite FETs you have which could well work here?