Hi,

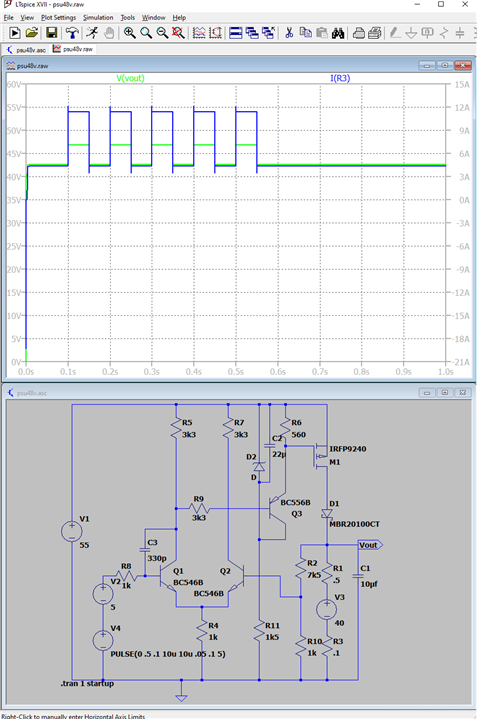

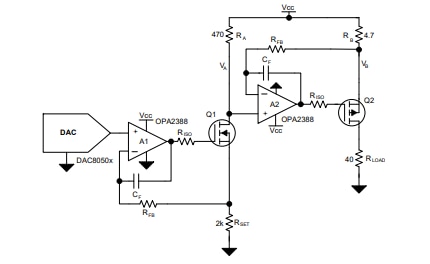

Im new here, first post, and am a fairly junior engineer so could do with some help regarding a charging circuit. I am designing a mosfet based current control circuit with a P-channel (needs to be high-side) and am having problems with the mosfet destroying itself. I have done some research into the use of mosfets in the linear region so I believe I am biasing it correctly and not putting much strain on it, keeping Vds low etc, but when trying the circuit out it works for about 10 seconds before a wisp of smoke and charming aroma fills the lab. I have tried several different mosfets now and had the same problem with each of them, all setup to work comfortably within specs.

After some more research I came across "Power Mosfets" which sounded like the answer to my problems, several articles I read talked about how standard mosfets cannot dissipate the heat being generated but power mosfets can. I started looking at the datasheets of some of these to select some samples but each one I looked at had the same issue which, with the knowledge I have so far, has ruled them out. The ZTC point on the transfer characteristics graph was very high.

My understanding of the operation of mosfets is that they need to be biased on (Vgs) above the ZTC point so that they are thermally stable. This is one of the key properties I have looked for in datasheets, along with the SOA, but what Im seeing with power mosfets is, for example, a ZTC point at 20A with a realistically useful maximum current of around 20A. This is of no use to me as there is no range. The standard mosfets have a much lower ZTC point so can be used to regulate current over a significant range which is what Im looking for.

Im starting to doubt some of the things Ive learned about these devices and so definitely need some help with some questions:

Ive got used to thinking that I can only use mosfets above the ZTC point but these power mosfets look like using them below it would be necessary. Im wondering if it is safe to do so, as long as you have a feedback system to back off the current as it warms up?? If this is the case, is it safe to use at Vgs extending all the way down to the Vgs threshold?

During research another confusing piece of info I came across, which completely contradicts what I had come to understand about power mosfets, was that they can fail in operation above the ZTC point even when within the SOA. I thought the whole point of a "power mosfet" was that it could handle operating in linear mode? Isnt this what differentiates it from a standard mosfet?

Im starting to wonder what it is Im missing with this as it seemed relatively simple to begin with so any help or advise on any of these points would be greatly appreciated.