Hello Friends and E/E Engineers,

I have bought this solder bread box for my new project. This is my first time to solder my own circuit.

I think it is the universal standard 0.1" pitch holes board.

According to your precious experiences, what soldering iron tip size and soldering wire diameter do you choose? Primarily, I do pass-though-hole parts plus few SMD.

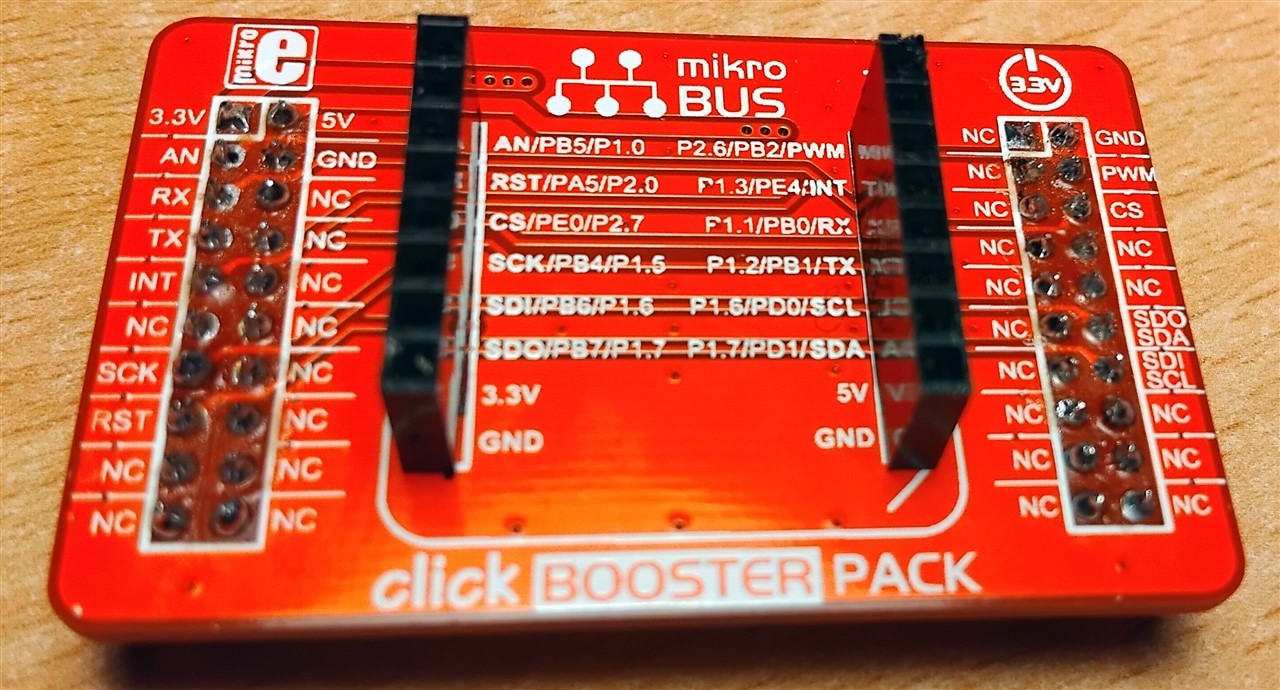

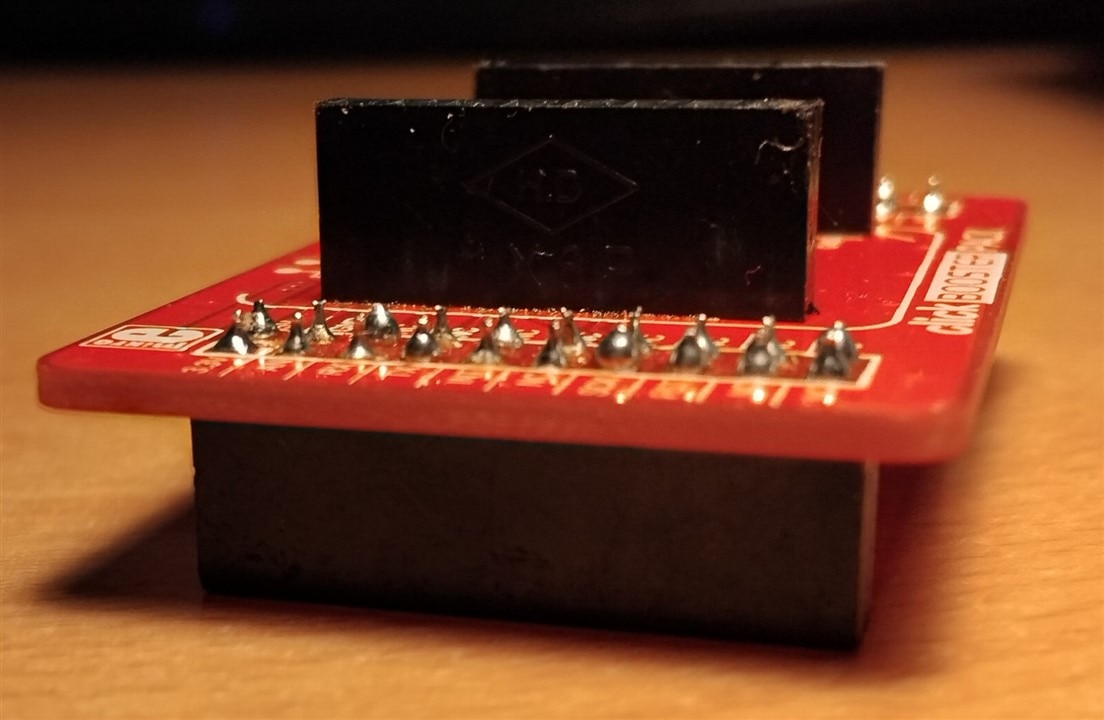

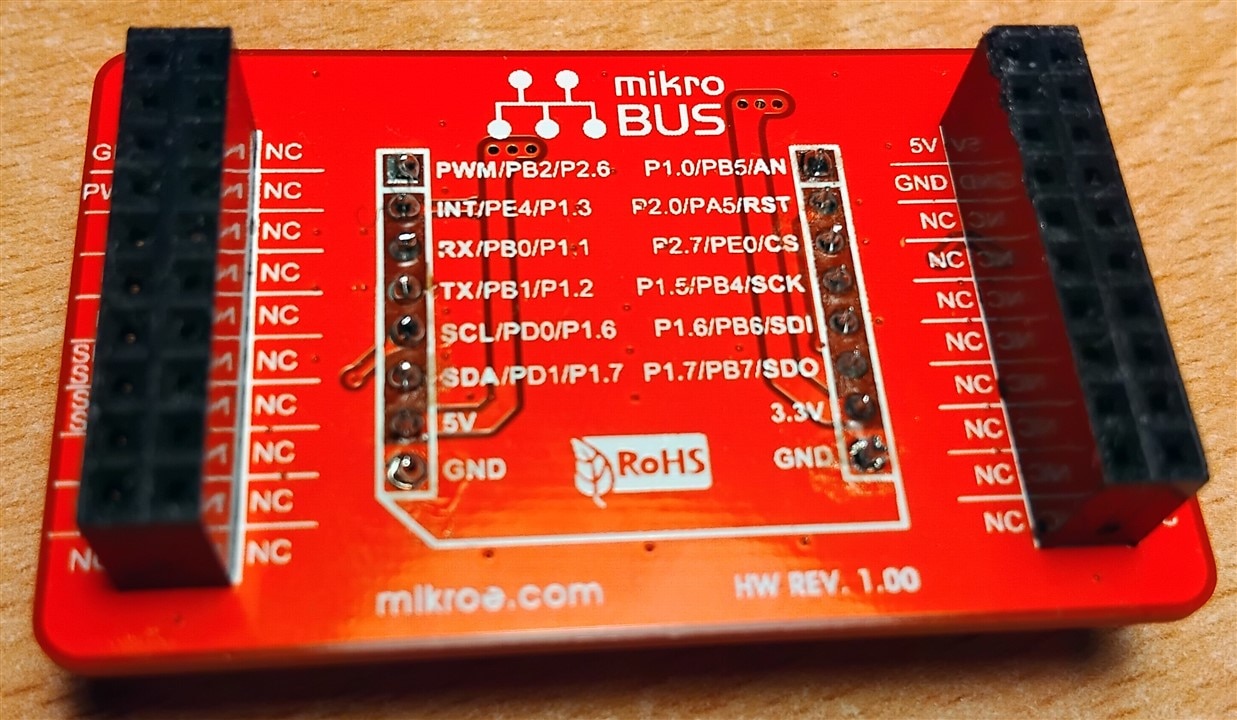

I did try a soldering iron tip in 1mm diameter and solder wire in 0.8mm diameter on this board but my solder joints seem too fat , not as slim as theirs shown here: