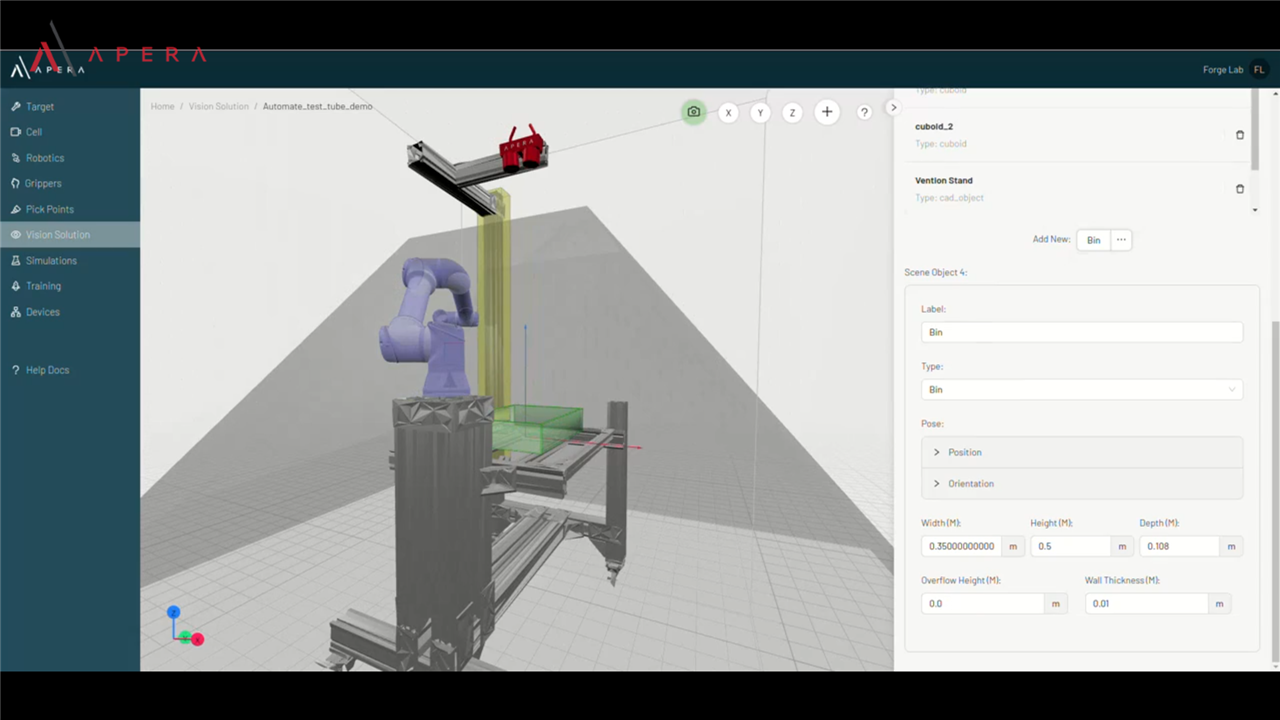

Apera introduced new features to its browser-based AI vision design studio. (Image Credit: Apera Forge)

Canadian company Apera has been advancing its browser-based AI vision design studio called Apera Forge that streamlines 4D vision-guided robotics automation projects. It has implemented new features, including support for advanced robotic cell design, end-of-arm tooling (EOAT)-mounted camera setups, and full training and simulation for de-racking applications.

Apera says the AI-powered system doesn't take much time to build vision-guided robotic cells for material handling, de-racking, and bin picking, and with lower risk compared to traditional methods. Industrial manufacturers may use this system to develop vision-guided robotic (VGR) automation projects in hours, rather than months or weeks.

The process begins by simulating the application, including components, grippers, robots, and the cell environment, taking only minutes to complete. Afterward, Apera Forge trains an AI neural network using a million digital cycles, achieving object recognition and task performance at 99.9% accuracy. With this approach, the system can build a full vision application within 24-48 hours, making it ready for on-site deployment.

Apera Forge enables users to design, fine-tune, and verify their bin picking and de-racking cells in a simulated environment. There's also no upfront hardware costs involved, which means users can train the AI vision project for the real world.

Additionally, the latest upgrade improves the system's capabilities, enabling more advanced cell design, with greater flexibility for bin positioning, fine-tuning camera placement, and integrating multiple obstacles. Users can import full cell configurations, use reference cell CAD files for improved visualization and precise scaling, and freely position cameras and bins. Meanwhile, features such as Obstacle Autopilot enhance robot navigation and collision avoidance.

With the EOAT-mounted (eye-in-hand) vision configurations, users can preview and refine camera views for camera systems mounted on end-of-arm tooling. This simplifies the design and validation process for de-racking and bin placement applications. De-racking simulation and parameter control, including rack orientation, initial position, part spacing, and quantity, enable simulations to achieve real-world layouts and enhance precision.

"Forge now supports full simulation and AI-powered training for de-racking applications. Simply define structured part layouts, simulate picks, and train vision models for faster deployments, with complete self-serve training and validation inside Forge," Apera said.

Have a story tip? Message me at: http://twitter.com/Cabe_Atwell