The PixONE platform packs a 6-axis IMU, gyroscope, temperature sensor and can handle payloads up to 250 kg. (All images via Bota Systems)

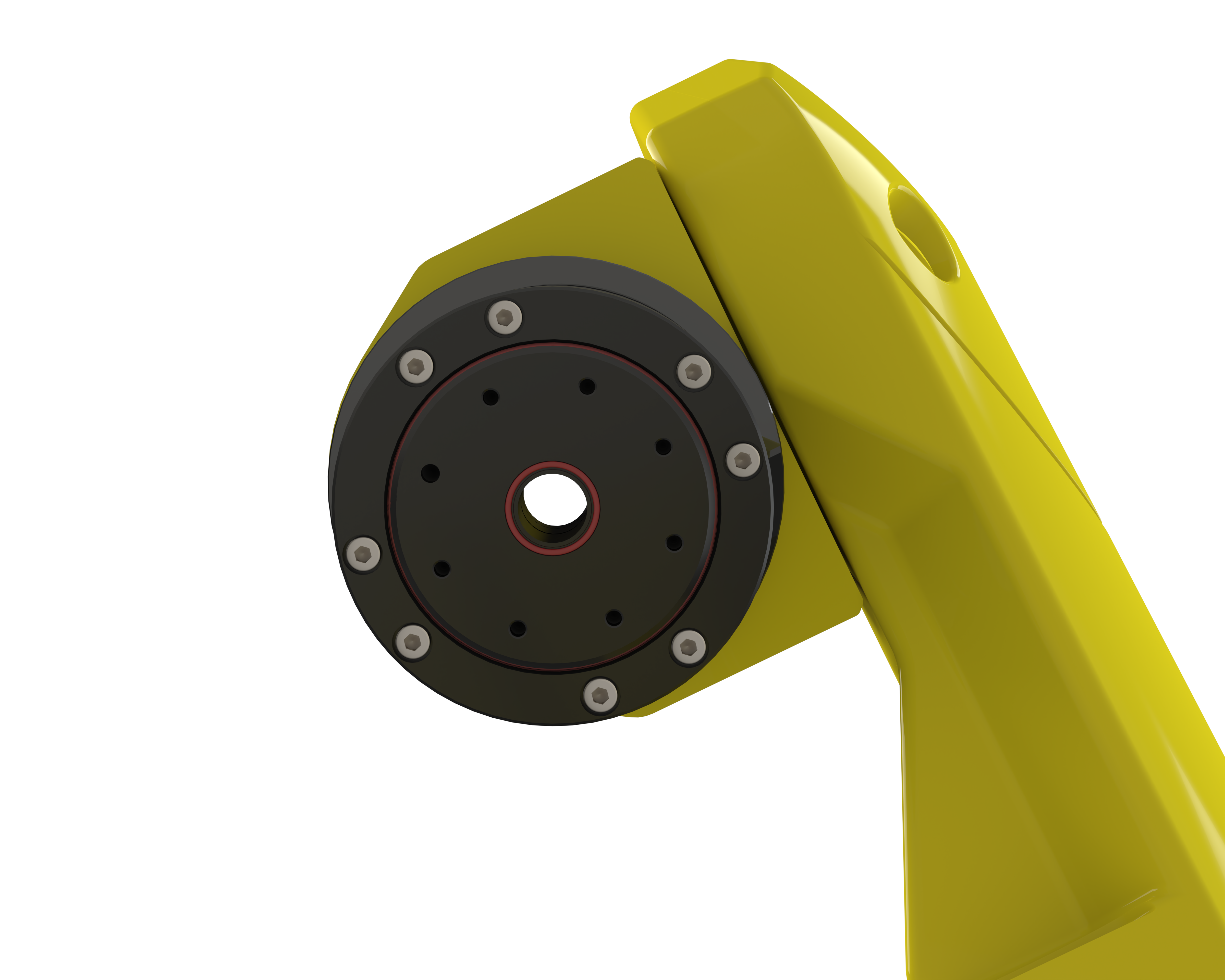

Bota Systems, a Zurick-based developer and manufacturer of multi-axis force-torque sensors, recently unveiled its latest next-gen through-hole sensor with integrated electronics housed in a compact, lightweight design. The PixONE is an industrial 6-axis force torque sensor designed for industrial and advanced robotics applications and features integrated electronics and a novel hollow shaft design, allowing for internal cable routing between a robot's arm and its end-of-arm tooling (EOT). It also helps to mitigate cable tangling and motion restrictions.

"Our objective is to equip robots with the sense of touch, making them not only safer and more user-friendly but also more collaborative," stated Klajd Lika, CEO and Co-Founder of Bota Systems. "PixONE is an advanced, OEM-ready sensing solution that enables robot developers and integrators to effortlessly enhance any robot in development with minimal integration effort."

The PixONE sensor features a compact, dustproof, water-resistant (IP67-rated) two-piece housing to help streamline assembly and reduce weight by 30% compared to other sensors on the market. Weight reduction is critical for dynamic systems such as fast-moving robots where weight can impact performance and navigational efficiency.

The sensor also comes equipped with a 6-axis IMU, gyroscope, temperature sensor, and a pair of EtherCAT ports and supports PoE (Power over Ethernet), facilitating daisy chain connections in a wide range of environments. What's more, the PixONE can handle payloads of up to 250 kg, making it ideal for use in pick-and-place and assembly line operations. The sensor can also take advantage of several open-source software platforms, including ROS, LabVIEW and MatLAB.

Have a story tip? Message me at: http://twitter.com/Cabe_Atwell