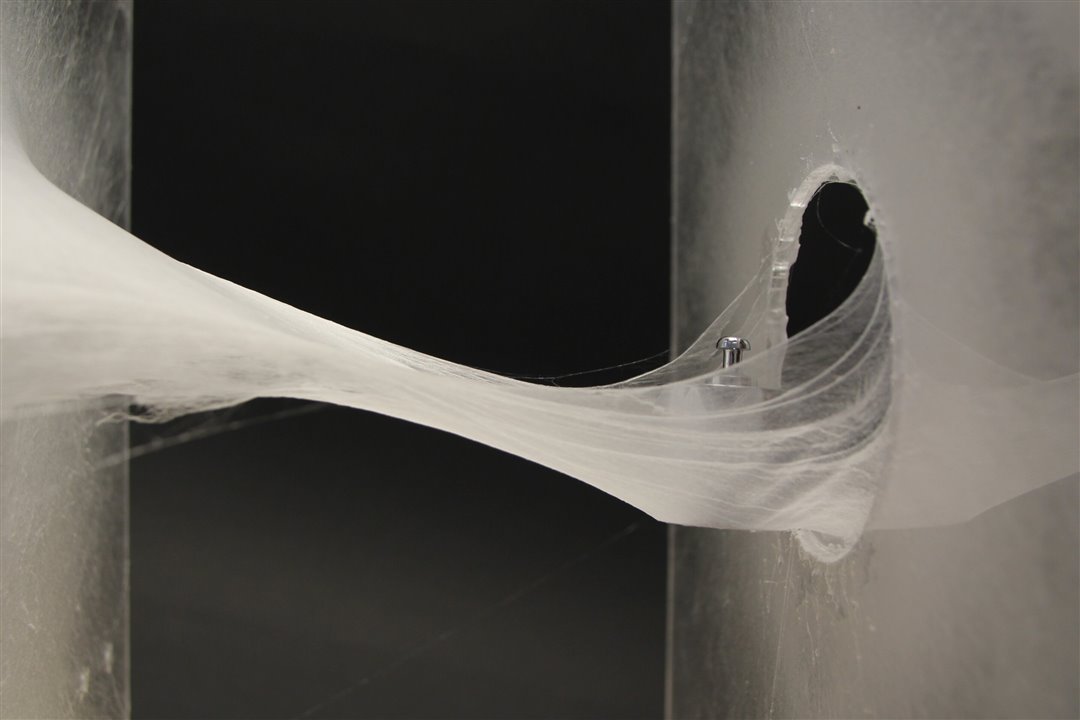

The robot spun a bridge with a steel balance weight supporting it to demonstrate the load capacity. (Image Credit: Marie Vihmar et al.)

Robotic components are usually built in factories, which turn out to be rigid with no versatility. Now, robots can create their parts on demand as required for the intended application. Researchers at the Institute of Technology, University of Tartu, developed a spider-inspired robot that weaves its body to create physical components from a heated polymer that cools into solid fibers. The robot formed a gripper to handle delicate objects and a bridge to cross debris fields and natural terrain.

This robot is identical to spiders weaving silk threads. Once ejected, the heated polymer, which starts as a liquid before being extruded through a heated nozzle, sticks to surfaces, forming durable, flexible fibers. Those fibers are spun into varying custom structures depending on the environment and task. During experiments, the team demonstrated the robot’s functionality in complex environments. In one test, the robot weaved a flexible fiber network that formed a bridge across a simulated debris field filled with glass shards or bird feathers. This bridge had sufficient strength to support a toy car moving across it.

"Our approach takes a cue from spiders as nature's ingenious engineers, yet we found a loophole that lets us sidestep the limitations and excessive complexity of directly imitating spiders," said Marie Vihmar, lead author of the study.

The robot developed a two-finger robot gripper. (Image Credit: Marie Vihmar et al.)

In addition, the robot formed a two-finger pneumatic gripper that picks up delicate objects, like a flower, without causing damage. The robot developed the gripper on a printed pneumatic connector base. Two Nylon fishing line loops (one for each finger) were attached to the connector. Afterward, the robot blow-spun a web in one run with a propellant pressure of 1.0 bar, resulting in a continuously housed web with self-tensioning forming the final shape.

Some areas, including the connector-support interface, had several stacked surfaces. Other places, like the outermost surface that defined the gripper’s boundary, had a uniform development. To finish the gripper, the team coated it by spray painting it with silicone elastomer, which also filled in holes by surface tension. They also repaired pinhole defects via partial dip-coating. Once the silicone was cured, the pneumatic effector, attached to a compressed air source, was ready for pressurization and operation.

With an internal hollow cavity, the completed gripper functions on the principles of conventional pneumatic deformable-boundary grippers. In this case, the fingers open at positive and close at negative pressure. Meanwhile, the web worked as a silicone reinforcement. The Nylon supports stayed inside the structure to limit strain, guiding and constraining the deformation to improve control, contributing to lift capacity, and retaining the shape.

These tools can be useful for robots in difficult situations requiring pre-built grippers to handle various tasks. The team’s robot also demonstrated the ability to anchor and stick itself to any substrate, regardless of the material, shape, or aggregation state. This includes oily sponges, waxy leaves, and slippery Teflon.

Similar to spiderwebs, mechanical entanglement, and physical adhesion helped the synthetic web attach to various supports. It can be used in real-world scenarios, including disaster relief. By creating bridges and safe pathways to quickly navigate dangerous areas, these robots have the potential to assist and improve search-and-rescue operations. It’s also practical for the construction and engineering sector as the robot can build temporary structures on-site.

Have a story tip? Message me at: http://twitter.com/Cabe_Atwell