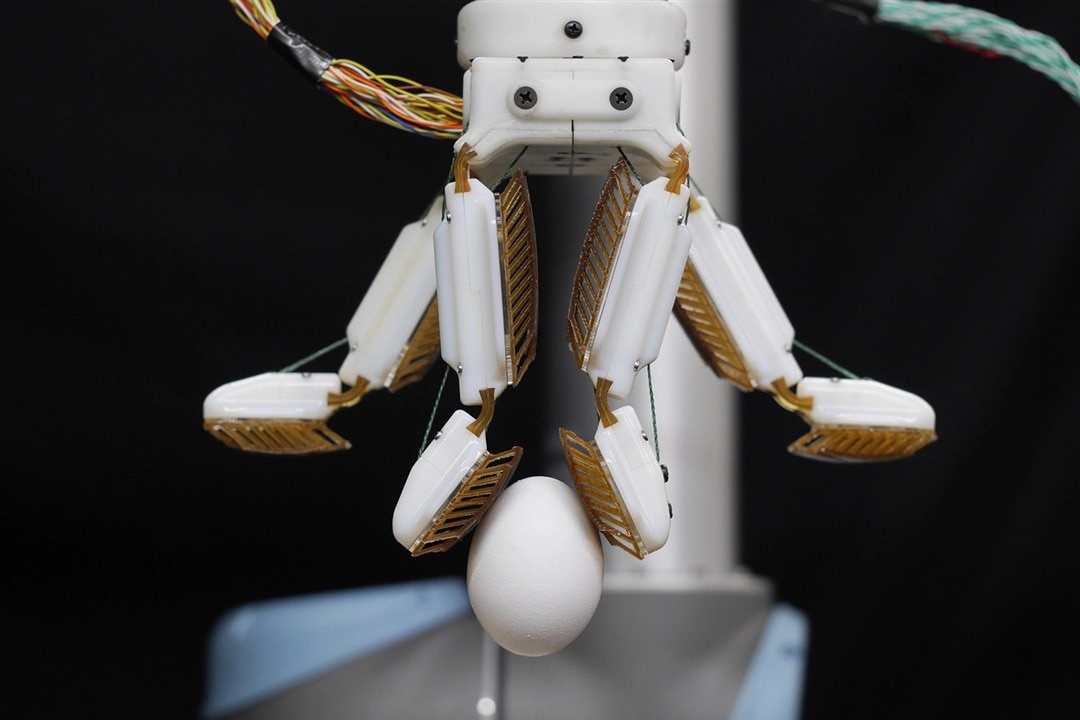

Farmhand is capable of performing hyperextended pinching, as demonstrated in the image above. (Image Credit: Stanford University/Biomimetics and Dextrous Manipulation Lab)

Stanford University engineers developed a robotic hand called farmHand that can grip and manipulate various objects, such as grapes, raw eggs, plates, jugs of liquids, basketballs, and an angle grinder. The robotic hand is designed around two different biological inspirations. For starters, the multi-jointed fingers, which have gecko-inspired adhesives, are strikingly similar to a human hand. The grippy material s based on the gecko toes’ structure.

However, using the gecko-adhesive on a multi-fingered, anthropomorphic gripper proved challenging. The gecko adhesive relies on tiny flaps, which generate a Van der Waals force whenever it comes in contact with a surface. This provides the robotic hand with a firm grip that requires minimal force. Even more, the adhesives aren’t sticky and don’t release any residue.

“The first applications of the gecko adhesives had to do with climbing robots, climbing people or grasping very large, very smooth objects in space. But we’ve always had it in our minds to use them for more down-to-earth applications,” said Mark Cutkosky, senior author of this research. “The problem is that it turns out that gecko adhesives are actually very fussy.”

The problem was that the adhesives needed to touch a surface in a specific manner to activate the Van der Weels force. Applying them on a flat surface makes it very easy to control the force, but it becomes more complicated when the adhesives need to grip an object from different angles. To solve this issue, the team integrated finger pads underneath the adhesives. These are composed of a collapsible rib structure that buckles with minimal force. This setup ensures that the ribs consistently buckle despite the region or angle of contact. It also provides equivalent forces on the adhesive pads while preventing slippage.

“If you move these ribs, the buckling results in a similar force no matter where you start,” said Wilson Ruotolo, Ph.D. ’21, a former graduate student in the Biomimetics and Dextrous Manipulation Lab at Stanford University. “It’s a simple, physical behavior that could be deployed even in spaces outside of robotics, perhaps as shoe tread or all-terrain tires.”

FarmHand’s tendons are also crucial because they enable a hyperextended pinch. Unlike other robotic hands that pinch objects in a “C” shape, farmHand pinches objects with the end of its fingers pressed pad to pad, providing more surface area for the adhesives.

It was also difficult to perfect the design since computer simulations have trouble predicting real-world performance with soft objects. However, quickly 3D printing and testing most of the hard and soft plastic components proved beneficial for the team. The engineers also say they wouldn’t have seen much success five years ago.

In the future, farmHand could feature some type of feedback to help users understand its gripping process and improve its grip. The team is also thinking of commercial applications for this project.

Have a story tip? Message me at: http://twitter.com/Cabe_Atwell