Actuators and Sensors are the crucial components for determining system performance. Systems in the automotive domain, such as power train applications, are prolific users of these devices. Sensors measure physical parameters such as temperature, flow, and pressure in a format appropriate for the digital microcontroller. Actuators modulate inputs that directly control their output. The main microcontroller is critically responsible for the complete actuators and sensors system, which receives information from sensors, synthesizes it, arrives at a decision for a particular activity, and provides the input to the fuel injector and other actuators. The fuel injector is an electrically driven actuator that regulates fuel flow to an engine for engine control applications. Advancement in automotive electrical-electronics (E/E) architecture adds stress to the already heavy development burden, and customers demand the development of efficient actuators.

The control system designer may not have access to an ideal device as commercial actuators and sensors may be unsuitable for that specific job; a customized piece may be expensive. The solution is to adapt special interface circuits or signal processors to an available actuator or sensor, linking to a system function controlling the central processing unit (microcontroller).

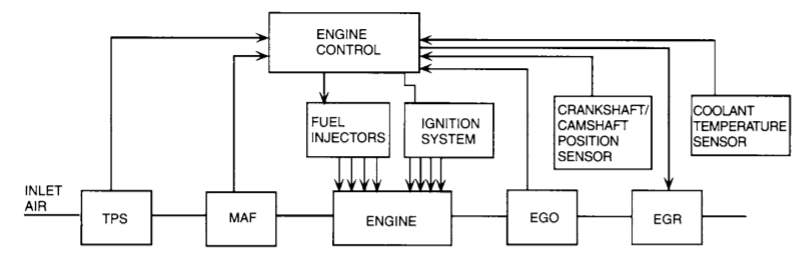

Figure 1: Different Sensors and Actuators in Electronic Engine Control System (Image Source)

Figure 1 shows a block diagram of a typical electronic engine control system (a sensor and actuator system) illustrating the most relevant sensors and actuators like temperature sensor, position sensor, fuel injector, etc., connected to an automotive microcontroller to control the engine.

The Renesas’s RL78/F24 and RL78/F23 automotive MCUs are designed for next-generation intelligent actuators and sensors applications. These support edge applications in electronic and next-generation (E/E) architecture with a CAN FD interface, providing actuators and zone control systems solutions. The RL78/F24 supports the CAN FD communication protocol and Evita-Light security and is optimized for ASIL-B levels targeting systems following the ISO 26262 functional safety standard. LIN is supported along with other connectivity interfaces.

Figure 2: Automotive Actuator and Sensor Control RL78 MCUs (Image Source)

Advancement of Control mechanisms led to the inclusion of automotive system body control to match the domain and zone control applications within E/E architecture. Automotive systems comprise multiple sensor control, lights, windows, motor control for engine pumps, mirrors, and fans.

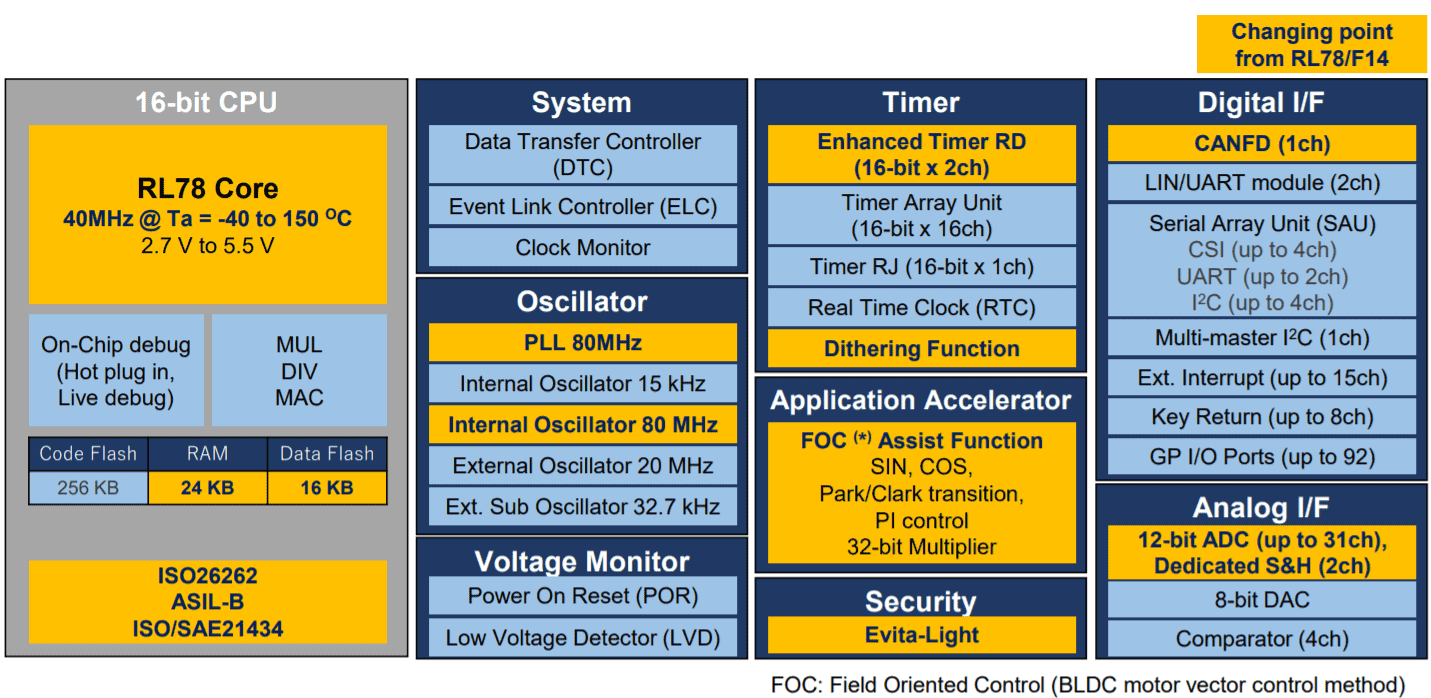

Figure 3: RL78/F24 Block Diagram (Source)

Secure and high-speed connectivity with domain and zone controllers from now on will be mission-critical for edge electronic control units (ECUs). These new generations MCUs’ address changing technology demands for actuator and sensor control with security, connectivity, and functional safety capabilities.

A vehicle-centralized, zone-aligned E/E architecture will dominate future automotive systems, igniting increased demand for better performance and advanced functionality in actuator controller applications. The brand new RL78/F24 and RL78/F23 MCUs deliver about 70 percent quicker-operating frequencies when compared to the previous generation, which can offer 2x and more performance within brushless motor control (BLDC) applications. Motor control timer and hardware accelerator functions are enhanced; the added 12-bit A/D converter provides better functionality and performance levels. The new generation actuator and sensor control MCUs build on highly popular RL78/F14 and RL78/F13 devices. These MCUs allow developers to recycle most software assets, minimizing costs while accelerating E/E architecture development with highly reduced power consumption.