Hi,

I'm a pcb-design newbie and I just finished designing one of my first pcb boards in Eagle. The design passed all the rule checks - but I want to make sure it will be OK when it arrives. Can anyone help me evaluate my design before I send this to the fab?

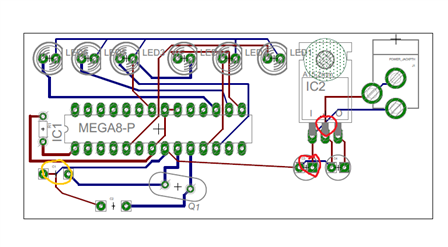

It's a basic design, where I use an Atmega 328 (along with its required voltage regulator, capacitors, etc.) and a series of LEDs I use to light up like the car from Knight Rider.

PDFs of my board and schematic are attached. Thanks, in advance, for all your help.