The Italcementi Group developed a new technique to make cement opaque but not lose its integrity. The Italian Pavilion, Shown at last year’s World Expo in Shanghai, the cement is made by mixing ‘special resins’ into the concrete. The Italcementi Group researchers have identified the right formulation of a dry ready-mixed product that allows inserting these plastic resins in the cementitious material, which is naturally opaque, without creating cracks and jeopardizing the structure. 3,774 transparent panels (including the “semi-transparent” ones, i.e. with a 50% lower transparency level due to architectural requirements) have been produced and were used to cover a total surface area of 1,887 m², approximately 40% of the total envelope of the Pavilion, creating in the building in Shanghai a sequence of lights and shadows in constant evolution during the day.

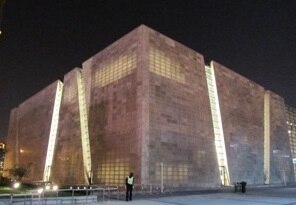

The transparent effect is more evident when it is dark and, seen from the outside, the building will allow the interior lights to filter through while, from inside, during the day, it will show the changes in the levels of daylight. The i.light material is cheaper than using optical wires embedded in the cement, which is what other builders of “transparent cement” have used. Moreover, the resins can let more light through than fiber optic wires and they mesh easily with the cement mixture surrounding them.

The transparent effect is more evident when it is dark and, seen from the outside, the building will allow the interior lights to filter through while, from inside, during the day, it will show the changes in the levels of daylight. The i.light material is cheaper than using optical wires embedded in the cement, which is what other builders of “transparent cement” have used. Moreover, the resins can let more light through than fiber optic wires and they mesh easily with the cement mixture surrounding them.

Eavesdropper