Training Bay Ventilation Automation

Updates of 03/02/2024 at end of blog.

This blog will evolve over time as I discover and share how to work with the equipment provided for Experimenting with Industrial Automation. There is a plethora of information on the web for the Schneider Electric devices. I hope to help folks who are new to it (like me) get to the useful stuff early.

Of course, Schneider Electric has tutorial videos. The true beginner series can be found at the link below. Not every video is applicable to the first time user, but with 69 in the play list... not only will you get the basics, but you can learn some capabilities that you might find useful.

https://www.youtube.com/playlist?list=PLFqT6GhMpgpI5lYxJBCmI8N84eV3uhbEr

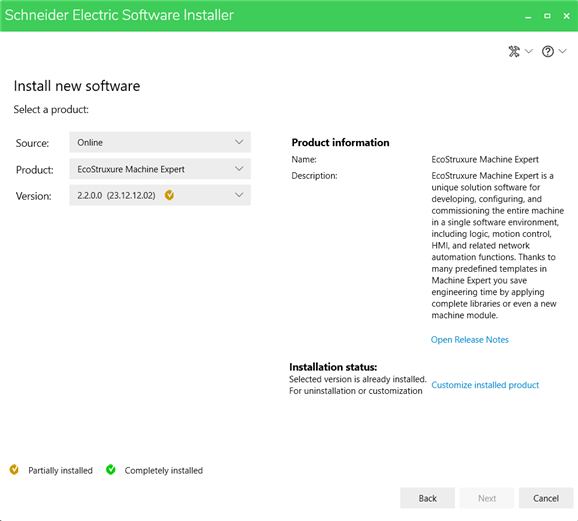

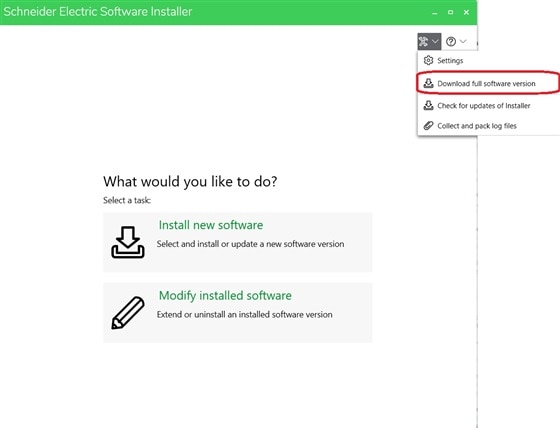

Video 7 of the above group of videos covers installation of the EcoStruxure Machine Expert software used with the current line of PLCs. There is no free version, but there is a trail version that is good for 42 days. The software installation will be a multi-step process that will require you to create an account with Schneider Electric. There are also Add-ons that you will need to install to allow you to access the PLC. You can find the initial installation software at the link below or on posts on the Experimenting with Industrial Automation forum. Credit rsc

https://www.se.com/us/en/product-range/2226-ecostruxure-machine-expert-software/?parent-subcategory-id=3910&filter=business-1-industrial-automation-and-control

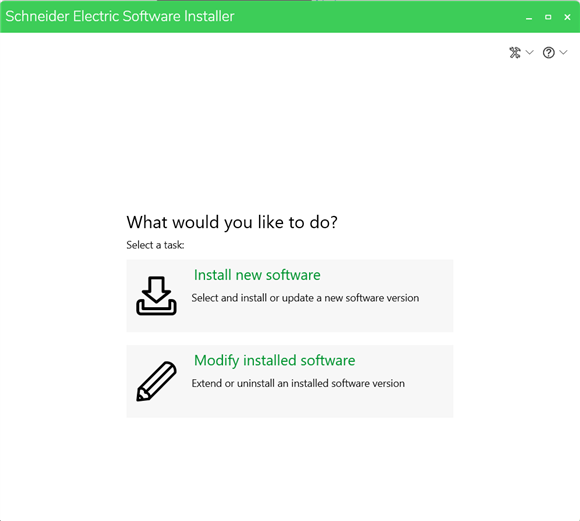

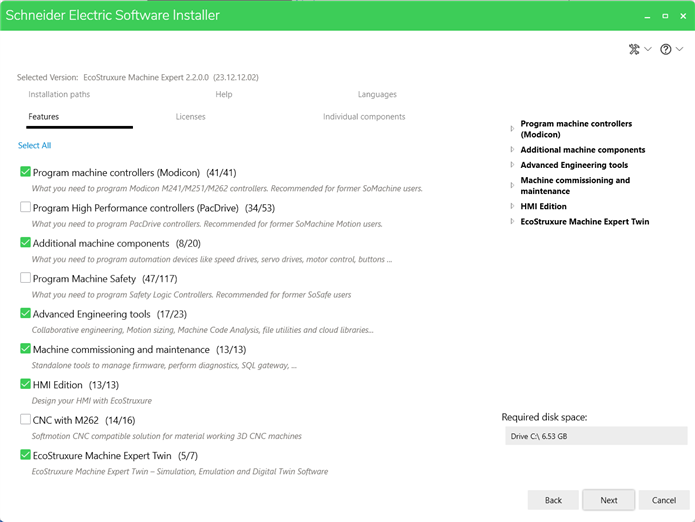

Launch the Schneider Electric Software Installer program. Select EcoStruxure Machine Expert. I chose the latest version. When you click NEXT, you will be able to select your Add-ons. The videos recommends everything. I left a few out. You definitely need Commissioning and Maintenance as this gets you Machine Assistant - which you need to update the firmware and reset the security to be able to access the PLC.

Of course, I didn't discover this little gem until afterwards.

Another useful link that I found was the Machine Expert Documents page. Many of these are web documents so you might need to do a lot of clicking, but it has structure - and that helps my thought process.

https://product-help.schneider-electric.com/Machine%20Expert/V2.2/LandingPages/en/index.html

Still left to figure out is communicating to the HMI and connecting to the Harmony Hub. More to come as I figure stuff out - or others share their knowledge.

Updated 2/21/2024: Things I have learned up to this point.

1. I/O on industrial PLCs are wired differently than SBCs and more basic PLCs. I wanted physical IO so I added an IO module. On these, you need to "bring your own power". For the inputs, it's Input Common to power source to contact to Input Channel. My Input Channels worked with a 9v battery as well as the 24V power supply. They do not work without adding power to the circuit. You can also choose to switch positive or negative voltages. The output relays were set up the same way.

2. When you add you program (Program Output Unit - POU), you also have to drag and drop it under the MAST (MASTer task - think 'Main Loop'). Otherwise, it won't run.

3. Industrial PLCs do not auto-run. The instructions say that the can under certain conditions. They don't.

4. Mar 2, 2024: I am wrong. The Harmony Hub needs the external antenna connected. When the operator's manual says that you should not have any devices between the Hub and the receiver, they are serious. The signal couldn't make it 4 feet across the table. Admittedly, there was a laptop, two DIN rail power supplies and a PLC in the direct line, but it's also only 4 feet.

While the above is still true, in testing the range of the wireless components not through a bunch of devices, I almost ran out of building before I ran out of signal. What I experienced was an anomoly of bench testing.

Update Feb. 28, 2024: HMI to PLC communication. Functional

To allow the HMI to interact with the PLC, we need another piece of software - EcoStruxure Operator Terminal Expert. Like the EcoStruxure Machine Expert, there is no free version but there is a trial version that is good for 42 days.

https://www.se.com/us/en/product-range/62621-ecostruxure-operator-terminal-expert/#software-and-firmware

Problem: EcoStruxure Operator Terminal Expert trail version does NOT allow uploads to a physical HMI

Credit to pandoramc

The training video can be found here: https://www.youtube.com/playlist?list=PLFqT6GhMpgpLuW145nJtN_snkrekeNpoG

According to the videos, this should be easy. My system is still not communicating. I have all of the security disabled so it should exchange data freely.

2024-02-28: Fully functional software was the key to getting the HMI to work. What ate up days in a futile attempt to emulate the HMI happened in minutes on the real HMI.

Update Feb. 23, 2024: PLC to Harmony Hub communication. Functional

2024-02-22: I am able to read MODBUS registers for the paired ZBRT2 transmitter modules (switch contacts) using a MODBUS scanner. Once I added the external antenna to the Harmony Hub, I was able to write to the output registers that are tied to the ZBRRH receiver module and have them respond. The paired output channel contains four 16-bit words (Channel 0: 2100, 2101, 2102, 2103). 0xFF or 255 (bits 8-15) in any one of the addresses turns the corresponding output on the ZBRRH receiver module ON. Writing 0 to the address turns the output OFF.

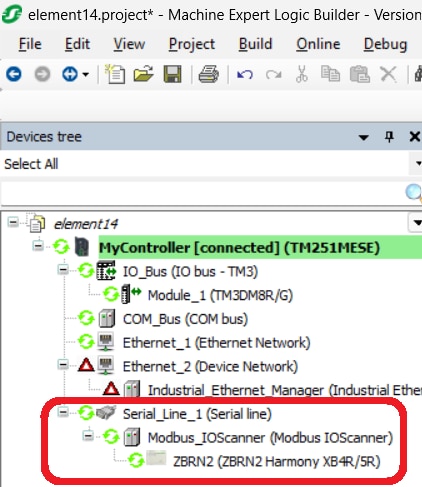

To allow the PLC to read these values, I needed to delete the Machine_Expert_Network_Manager on Serial_Line_1 and go with the Modbus_IOScanner. Then I was able to add the ZBRN2 Harmony Hub and see the inputs.

The "partially functional" is because I am not able to get the PLC to write to the output channels yet, but I'm close. I can get my annunciator lights to go ON and OFF if I force the values in my PLC program. I'm having issues converting my Boolean status to two different MODBUS write statements. Trying to do a parallel conversion from Boolean to Word interfered with my IO mapping. I don't think I'll ever figure THAT one out. So close and yet so far.

The current status of the project is that it performs the functions that I wanted it to do but I do not have the annunciation and display that I wanted. So while it is functional, it still hasn't achieved "cool" status. The ability to carry a light-weight control station in your hand and not have to crawl through the attic to run wires (which I did for the door control) is still pretty awesome. Hopefully, with the training videos and some of the comments above, a new person could make this systems work in a reasonable time. Any modifications after that should go fairly quickly.

2024-02-23: The annunciator panel now works as expected. There were enough steps in this that I will create a separate blog.

I never did find a blog, video or FAQ that tied the communication pieces together - so I made something.

Setting Up IO on M251 PLC Through ZBRN2 Harmony Hub - 3

Short synopsis: I swapped the ZBRN2 for a Generic_Modbus_Slave and added an input and an output channel. Once I figured out that the output addressing was in HEX, life got better.

As stated above, anytime I tried to convert the Boolean outputs on my ladder to the 16-bit Word I needed to drive the ZBRN2 outputs, it would mess with the mapping. I got around this by using MOVE and then performed the conversion. I used Structured Text to change the values to my desired outputs and now it finally works.

The last piece of the puzzle is the HMI. rscasny has secured the participants some licenses and (hopefully) that is the magic to allow the communication I need to get the HMI working.

I guess I should get working on my final blog.

2024-02-28: The HMI works. Fully functional software was the key. I never did get the simulation (full or trial version) on EcoStruxure Operator Terminal; Expert to work BUT the real upload behaved as it should. The trial version of the HMI software either needs better functionality or better guidance on how to make the simulation mode work correctly. I spent days on trying to get it to communicate with the PLC (or at least pretent to). Frustrating. The PLC also needs to be in RUN mode to exchange any data.

My project is fully functional. Now I just need to nail it to the wall and hook up a few wires. How hard can it be?