About me

Hello everybody!

Nice to meet you. I am a software engineer but, because of my expertise (which is an edulcorated way to say I am old), I am more on the management side of software development. During my spare time, I like to make my projects without all the burdens that professional software development brings (documentation, testing, customer support). My projects are aimed to explore new technologies that I have no the opportunities to experiment with during my daily job

About the challenge

In this challenge, I would like to evaluate whether the Kemet thermal resistors suit two projects I have in mind to improve the energy efficiency of my house

Fume energy extractor

The heating system in my house has two main zones. Ground floor (where we typically live) has a floor heating system, whereas first floor (where there are two rooms we use rarely) has an heating system with water radiators.

A floor heating system has a major main advantage: low temperature (up to 40 °C) water can be used to heat the ambient. This is an efficient approach to heating, because many highly-efficient technologies can be used to generated low temperature water required by the system. The optimal solution in terms of efficiency would be probably an electrical heat pump. However, at least here in Italy, this is not the best solution from a financial point of view, because electricity cost is quite high and, when I built my house, photovoltaic panels were very expensive. So, at the time, the best compromise was a condensing boiler. When used to generate low-temperature water, a condensing boiler has a very high efficiency because it can extract extra heat from fume by condensing water created as a result of the combustion of methane. Thanks to the condensing process that takes place before the flue, fumes have a low temperature (60 - 75 °C according to the boiler installation manual)

However, as I said, I also have some radiators, which require hot water (about 65 °C). When the boiler has to generate hot water, condensing process can not take place and fumes are much hotter (well above 100 °C). This is obviously an waste of energy. The problem is: letting the "cold" fumes pass through the heat exchanger will further cool down the fumes, causing them to stagnate because they may not have enough energy to go up through the chimney

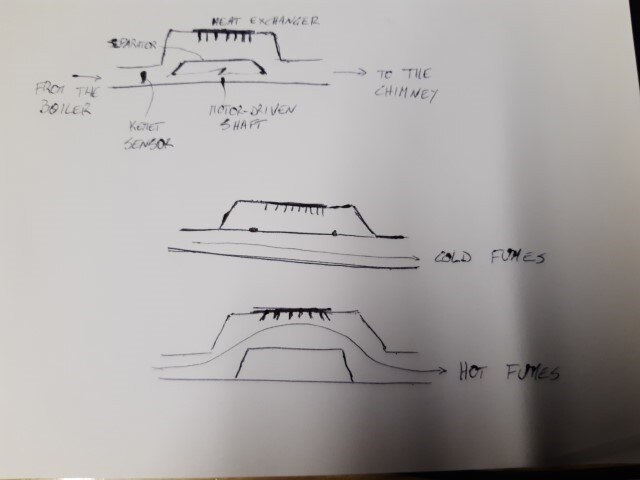

The idea for the first project is a control circuit that can detect the fumes temperature and, in case they are too hot, it diverts hot fumes to an heat exchanger so that some of the otherwise wasted heat can be sent to the room where the boiler is installed. Since we use to dry clothes in the boiler room, this extra heat would be welcome during cold and wet days

This is draft of the fume diverter (seen from top)

I think I will be able to implement the control logic using passive components only (a relay, a couple of limit switches and a motor to drive the diverter)

Solar panel water mixer

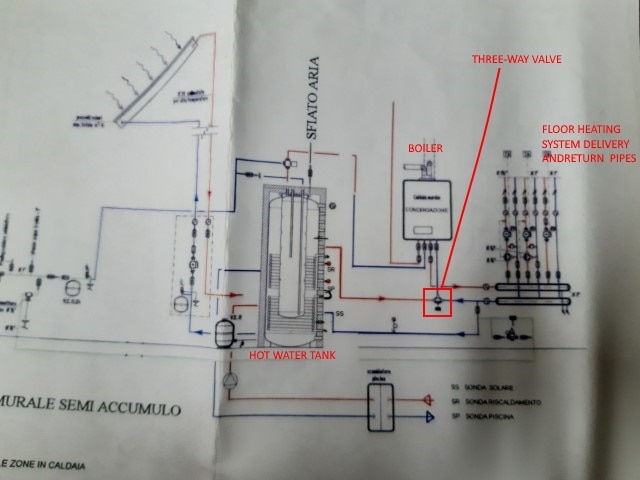

The second project is again related to energy efficiency. I have some solar panels installed on the roof that contribute to the heating during late fall and early spring. The water heated up by the sun is sent to the floor heating system. This is a diagram of the plant, where I highlighted the main components

As I said, floor heating system can only stand to water up to 40 °C. Occasionally, during warm and sunny days, it may happen that solar panels generate water as hot as 50 - 55°C. Should such a hot water be sent to the heating system, it could create damages because of thermal dilation of the materials the floor and the tiles are made of. In such condition, a thermal protection switch intervenes to prevent any damage. The problem is that the thermal protection switch (which is absolutely good) completely stops the house heating system. This is a big issue when this happens when you are out for the weekend and enter a freezing house when you are back. Also, the thermal protection switch has to be rearmed manually, which is a bit annoying.

The idea is to build a control circuit that can mix excessively hot water from solar panels with cold water that returns to the boiler after having passed through the pipes of the floor heating system. The circuit will use two thermal sensors

- a low temperature sensor: when water from solar panel is too cold (below 30 °C), there is no need to send water to the heating system

- a high temperature sensor: when water from solar panel is too hot (above 40 °C), the control system will open and close the mixer valve in a timely manner. In this way, the thermal capacitance of the house floor will dampen the thermal peaks. I chose this approach because currently I have a on/off valve to control the flow of water coming from solar panels. The optimal solution consists in replacing the digital valve with a three-way valve that can be controlled with an analogue signal, but this is going to be very expensive

- when water temperature is between the two thresholds, the water can be safely sent to the floor heating system and the valve will be fully open

The plan

The plan for this challenge includes the following steps

- Validate the sensor that best fits requirements for these two projects. I will build a simple test instrument to validate sensors in terms of accuracy and repeatability

- For sensor to use in the first project, I will also check the resistance of the sensor to high temperature (up to 150 °C)

- Build the circuit and a working prototype for the fume energy extractor

- Build the circuit for the water mixer