1. Introduction

Thermal Guard (OHD) are temperature-sensing switches composed of a magnet and a temperature-sensing soft ferromagnetic substance called Thermorite. This material’s saturation magnetic flux density decreases as the temperature increases, and it turns into a paramagnetic substance at its Curie temperature.

It all goes back to the famous French physicist Pierre Curie (also known for the work he and his wife did on radiation). Curie discovered that at a certain temperature permanent magnets will lose their magnetic properties. This temperature is now the so-called “Curie Point.” Fast-forward about a hundred years or so and enter scientists and engineers at TOKIN. They are a leading expert in manipulating the magnetic properties of materials so that they can be used in electronics. One way of manipulating the Curie temperature of a material is to add a very controlled amount of dopants. Careful control of particle size can also affect a material’s Curie Point. Using techniques such as this, TOKIN has created a material whose Curie Point can be very carefully controlled and adjusted. That material, known as Thermorite®, is now used in creating a thermal switch that opens or closes when that very specific and tightly controlled temperature is reached.

Thanks to the properities of the physical characteristics and build process, we can say that:

- Thermorite changes its magnetic property rapidly at its Curie temperature, providing quick response times.

- The Curie temperature of Thermorite does not vary with time, as it is based on a compounding ratio

- Thermorite is stable against moisture and hazardous gas because all the component (like the reed switch) are moulded in a thermal conductive package and, as such, protect by external corrosive compounds

For the above-mentioned reasons, a Thermorite-based solution is better than a thermistor solution or a solution based on bimetallic elements from several points of view

- accuracy

- overall robustness thanks to the reed switch, which is less subject to wear than a metallic switch

- response time

- relatively low hysteresis

2. Validation

The first step of this challenge is the validation of the provided thermal switches. Obviously I am not going to test whether the rated temperature and accuracy are correct, but I will try instead to check if there are any caveat related to the installation method I have in mind. I will focus on the switches that are in temperature range I need for the two projects I want to build. In particular, for the first project (fume energy extractor) I will use part OHD1-90M (thermostat switch, thermal guard, ohd series, axial, 90C, normally open). The reasons for this choice are

- It has a the desired temperature threshold. After some tests, I will check if it's better to apply a higher threshold (110)

- it is normally open. The boiler is expected to work most of the time in condensing mode, thus producing low temperature fumes. I want the control circuit to be completely off the boiler works in condensing mode to optimize energy consumption. This also allows me to implement a intrinsically safe mechanism, because, in case of issues with the control circuit, the fumes will not be diverted and, and as a conseguence, there is no risk of stagnation

- the package can be installed in the fluke so that is invested by the fumes. This criteria made me exclude, for example, the screw type thermal switches

- it is rated for current up to 300 ma. This makes this switch suitable to drive the relay coil directly

For the second project (water mixer), I selected the following items

- OHD1-30B (thermostat switch, thermal guard, ohd series, axial, 30C, normally closed)

- OHD1-50B (thermostat switch, thermal guard, ohd series, axial, 50C, normally closed)

These components has been selected for the same reasons, namely

- temperature threshold

- for the OHD1-30B, unfortunately the kit does not include a "Make" (normally open) version. With a normally open version sensor, I could have used the thermal switch to power up the control circuit

- the package can be installed on a pipe

- for the OHD1-30B, is rated for current up to 300 ma, which is enough to drive the electronic circuit I have in mind

The TRS series would probably be a better option for both these applications, because it has a better accuracy (2.5% for the TRS series, 5% for the ODH1 series), but the kit provided for this challenge did not include a TRS thermal switch with the threshold I need.

As I said, I am going first to validate the selected thermal resistors. I have neither the expertise nor the instrumentation to perform tests at a level of accuracy Kemet has done in its laboratories, but I will focus on measuring the stability of switching temperature for the specific mounting solutions I am going to implement. This means I will heat up and cool down the sensor repeatedly and report the actual temperature in a graph. I expect not to see any relevant drift from the rated switching temperature.

2.1 Test bench setup

To validate the selected switches, I created a automated test bench that is made up of

- an Arduino board

- a relay, to switch on/off the heater. The heater comes from a 3D printer heated bed and has a power of about 60W

- a reference temperature sensor. I will use a MAX6675, a temperature sensor with a resolution of 0.25°C that can measure temperature from -20°C to +600°C. It communicates with a microcontroller via SPI interface

The test bench can perform the following steps an adequate number of times

- switch on the heater (a control algorithm that uses the feedback provided by the temperature probe increases the temperature at a given rate - for example 1°C every 30 seconds)

- monitor the status of the sensor (all the selected switches are normally open, so in this step I will wait until the switch closes)

- send temperature measured by the reference probe to the logger

- wait until temperature increases by 20%

- switch off the heater

- monitor the status of the sensor (wait until the switch opens)

- send temperature measured by the reference probe to the logger

- wait until temperature decreases by 20%

- go to step 1

Sketch code is quite straightforward, and is available on github

The sketch continuously monitor the sensor probe and the status of the switch and, when a change in status is detected, it outputs on the serial line the following information:

- the temperature measured by the MAX6675 sensor

- the switch status (1=open, 0=closed)

An example of serial line output is:

30.00;1

22.25;0

30.25;1

22.50;0

29.50;1

...

2.2 Mounting solutions

First of all, the face opposite to the marked face in contact with the surface to monitor as suggested by the OHD1 datasheet.

For my two projects, I will mount the sensors in two different configurations. however in both case I will try to follow the suggestions in the OHD datasheet about optimal mounting. In particular, thermal switches needs to be mounted with the face opposite to the printed face in contact with the surface being monitored

2.2.1 Air flow-hit sensor

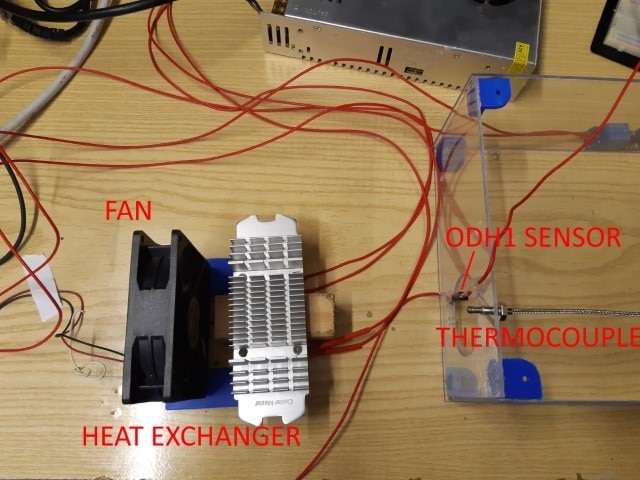

For the fume energy extractor project, the sensor is immersed in a flow of hot fumes. I am going to simulate such a flow by means of a heat exchanger where I drilled some holes to place one or more heater. A fan will blow through the fins of the heat exchanger and the heated air flow will invest the ODH1 sensor and the temperature probe. To improve measure accuracy, the temperature of the air flow will be increased gradually at a rate of 1°C every 10 seconds. Such a slow heating cycle allows the heat, transferred by the hot air the surface of the sensor, to flow inside the sensor material and warm evenly all the internal components.

2.2.2 High temperature

One of the two sensor provided in the kit will be sacrificed to test the maximum temperature the switch can stand. In particular, I will test if the switch can stand a temperature of 150 without damages nor changes in accuracy. I used a hot-air gun to simulate the scenario where the sensor is placed in a flow of hot fumes. Air temperature is monitored by a temperature probe. The duration of the test was 10 minutes. After that, the sensor has been retested by means of the test bench and here are the results

2.3 Pipe-mounted sensor

For the hot water mixer, the sensor will be mounted on the external surface of a steel pipe. This is not the best mounting option, because measurement is affected by heat transfer effects. However, installing a sensor that can "touch" the water requires the heating system to be shut down and emptied, and this is something that I don't want to do because it's very complicated, requires skilled labor and for sure is out of my reach. I'm interested in understanding at which temperature the Thermorite sensors are going to switch. To simulate this condition, I took a short piece of pipe and filled with water. I know this does not perfectly fit the real scenario, because in the real application the water flows through the pipe, but this is the best approximation I can think of

This scenario is more complex than previous one and many possible variations can be considered. First of all, the system has a relevant thermal capacitance and heat flows through different materials

For all these reasons, surface temperature measurement can be tricky. I tried to minimize to error due the mounting position by applying the following precautions

- I cleaned the pipe from any dust, rust and moisture

- To improve thermal contact between sensor and the pipe, I put some heat transfer paste on the contact surface

- I also use some thick paper to cover the sensor. Covering the sensor with insulation puts the sensor on the pipe’s side of the thermal gradient between the pipe and ambient environment. Thus, even with less than perfect contact with the pipe, the temperature of the sensor will tend to approach the temperature of the pipe. With out insulation, the ambient environment can have a significant impact on the temperature measurement.

- To take into account heat capacitance and heat transfer time, it is of paramount importance to have a slow heat cycle to allow all the parts to reach a thermally steady state. To determine the best temperature ramp, I increaed water temperature by 10°C and waited until the external surface of the pipe reached the same temperature. MAX6675 temperature probe was placed inside the water to keep water temperature stable. Temperature of the external surface of the pipe was detected by means of a clinical thermometer. After this experiment, I slowed down the heat cycle to 1°C per minute. The temperature I have to reach are not so high, so the test is going to last a reasonable amount of time.

For the real test, I installed OHD1 sensor and temperature probe as shown in picture below. Since I can no longer control water temperature using the feedback from the temperature probe, I changed the Arduino skecth by adding a table with heater on and off times for different temperatures. This table has been built by interpolating on/off times at 4 different temperatures

3. Results

3.1 Air flow-hit sensor

Here are the results for the OHD1-90M sensor. The absolute value of the switching temperature is probably not significant because my tests are affected by many errors (the major of which is the heat dissipation due to air speed, that probably greatly differs between the ODH1 sensor and the temperature probe because of their shape, size and external materials), but the stability looks quite good: the line that interpolates the sample points has virtually no slope

When used in an air flow, sensors accuracy looks very good, an I can appreciated the stability of the switching temperature even with my poor instrumentation. Air flow improves heat transfer and makes temperature sensing more reliable. I measured the temperature of the fumes generated by the boiler with the same thermocouple I used for the validation of the Thermorite sensor

The readings are

- 65 °C when boiler is working in condensing mode

- 107 °C when boiler is working in high-temperature mode

According to this readings, the OHD1-90M sensor looks a good choice

3.2 Pipe-mounted sensor

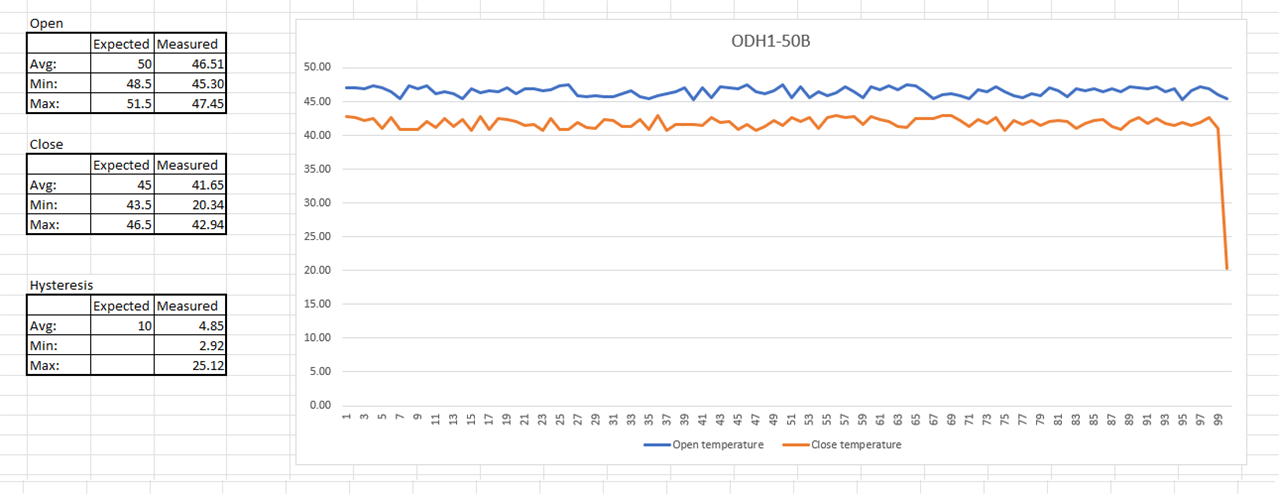

Here are the results for the OHD1-30B and ODH1-50B sensors. In this case, the average switching temperature I measured is significantly below the rated switching temperature. This is especially true for the ODH1-30B sensor, because the switching temperature is close to the environment temperature and, as a consequence, environment temperature affects the pipe surface temperature. However, the difference between switching temperature and detected water temperature is constant, thus supporting the hypothesis that this is just a systematic error due to the testbench and all the heat transfer phenomena I already mentioned

3.2.1 ODH1-30B

3.2.2 ODH1-50B

4. Conclusions

From this preliminary assessment, I can say that the mounting solutions I am going to adopt are proved to be effective and provides accurate and reliable detection of the temperatures. I will proceed with the build of the prototypes using the experience gained during these tests