A floor heating system has a major main advantage: low temperature (up to 40 °C) water can be used to heat the ambient. This is an efficient approach to heating, because many highly-efficient technologies can be used to generated low temperature water required by the system. The optimal solution in terms of efficiency would be probably an electrical heat pump. However, at least here in Italy, this is not the best solution from a financial point of view, because electricity cost is quite high and, when I built my house, photovoltaic panels were very expensive. So, at the time, the best compromise was a condensing boiler. When used to generate low-temperature water, a condensing boiler has a very high efficiency because it can extract extra heat from fume by condensing water created as a result of the combustion of methane. Thanks to the condensing process that takes place before the flue, fumes have a low temperature (60 - 75 °C according to the boiler installation manual)

However, as I said, I also have some radiators, which require hot water (at about 65 °C). When the boiler has to generate hot water, condensing process can not take place and fumes are much hotter (well above 100 °C). This is obviously a waste of energy. The problem is: letting the "cold" fumes pass through the heat exchanger will further cool down the fumes, causing them to stagnate because they may not have enough energy to go up through the chimney

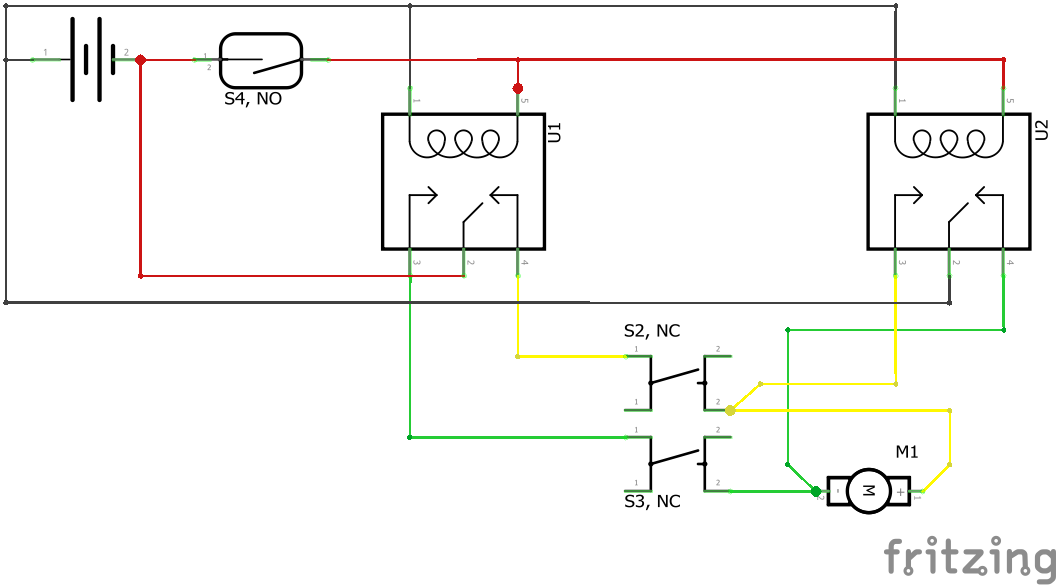

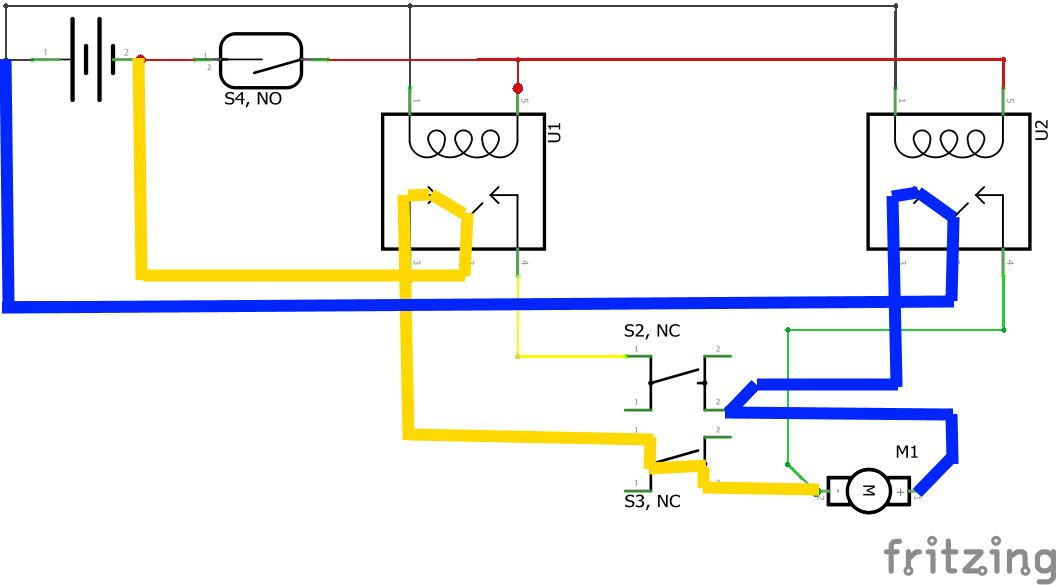

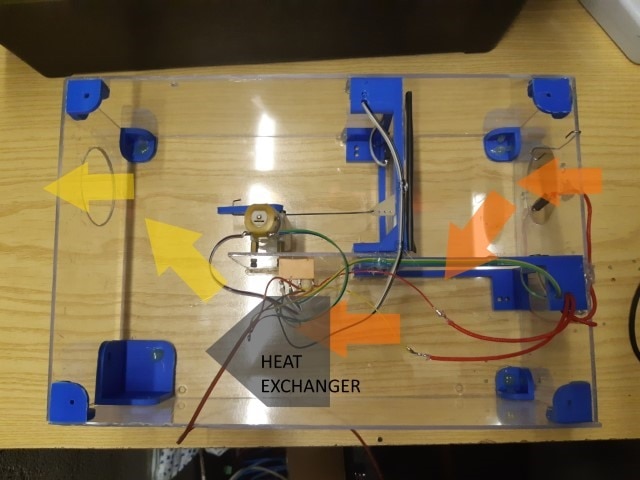

The idea for the first project is to build a control circuit that can detect fumes temperature and, in case they are too hot, it diverts hot fumes to an heat exchanger so that some of the otherwise wasted heat can be sent to the room where the boiler is installed. Since we use to dry clothes in the boiler room, this extra heat would be welcome during cold and wet days.

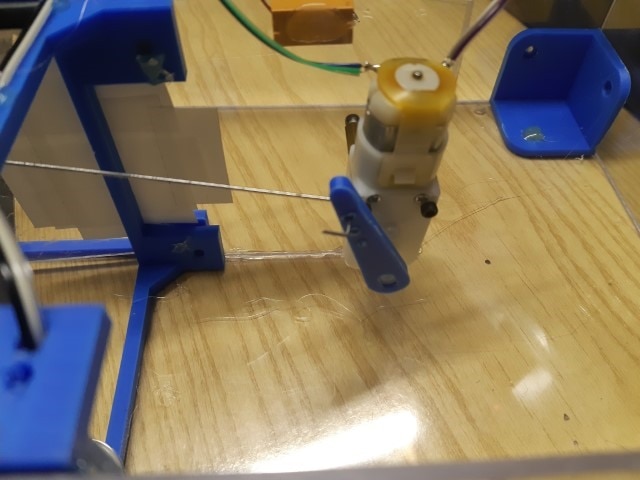

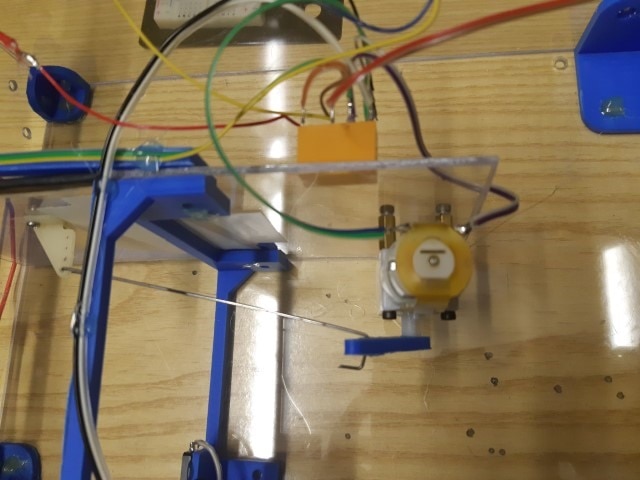

The Thermorite OHD1-90M switch has been installed on the fumes intake