Introduction.

This blog part will be about connector and enclosure parameters. As I have written, I plan to make comparison between three different enclosures - all rated at some level of water resistance.

Enclosures

The project involves three test enclosures:

- one completely sealed, rated at IP65 ("good" reference),

- one rated at IP65 but without cover seal installed ("bad" reference),

- one provided with my challenger's set - IP68 rated, with Amphenol connectors installed (device under test),

As can be seen, although reference enclosures are not specified to be submerged, they should protect at least from "water jets from any angle".

But first some information about former "good" reference - originally IP65 rated installation box that was planned as a reference. Unfortunately, after initial measurements it turned out that it's formidable rubber caps covering cable entry points are somewhat loose and in one position (about 1mm recessed) they are susceptible to leaking, so this enclosure had to be replaced with different model. There is a gallery of this installation below - at first look all seems good: openings are covered by rubber covers, there is a seal between cover and lower case, but covers can be moved +/-1mm and in one position they are leaking...

| {gallery}Failed IP65 reference |

|---|

|

Outside view |

|

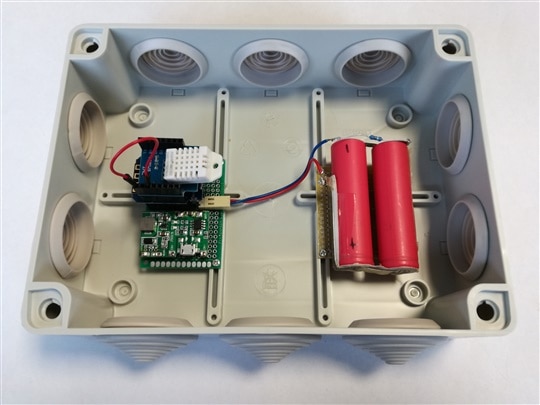

Sensor installed in the enclosure |

|

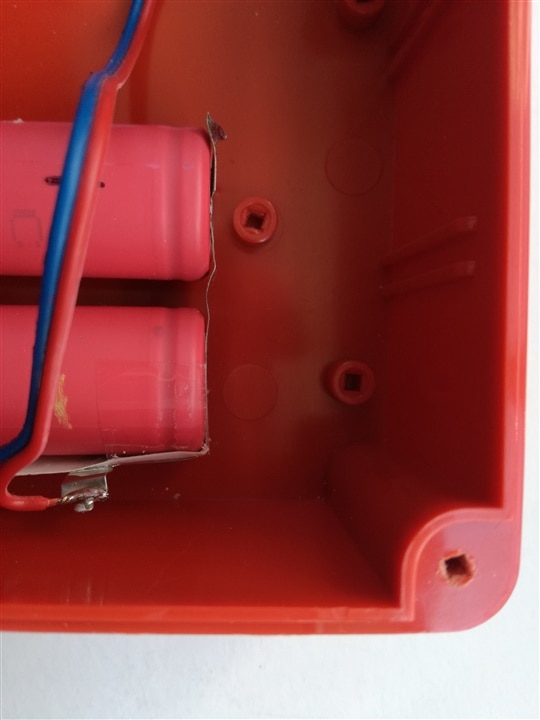

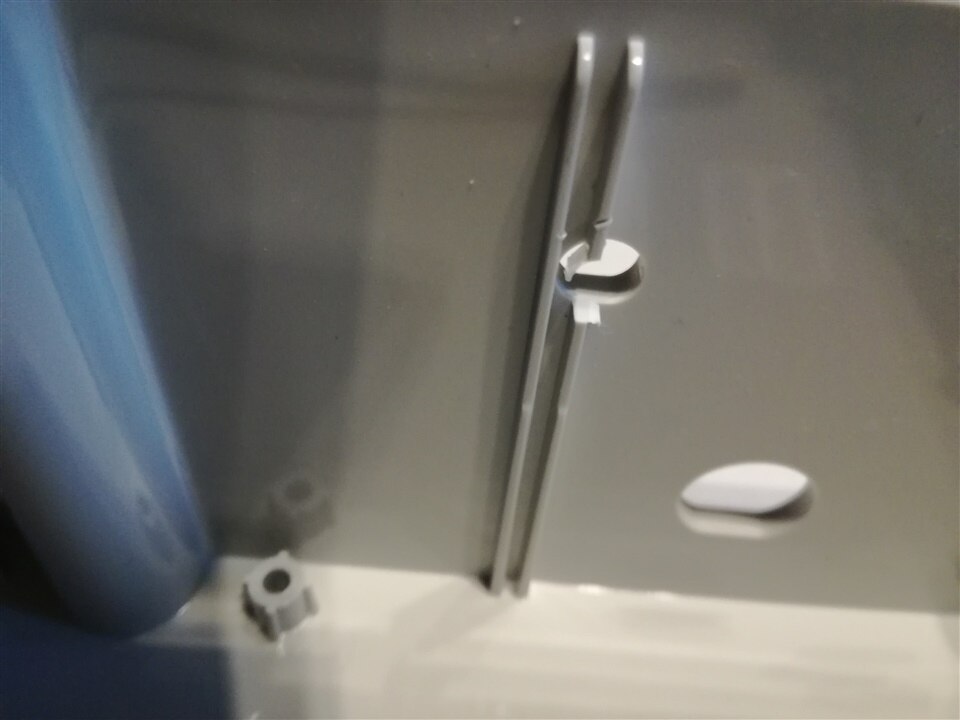

Details of the construction - cover seal |

|

Opening cover detail |

Two final reference enclosures are both Kradex Z74 "hermetic enclosures" - made from Polypropylene and ABS and with proof of testing against IP65.

https://www.kradex.com.pl/products/905/Z74.pdf

As can be seen - they are similar (but smaller) to Hammond 1554VA enclosure provided in the challenger's kit. Below there are photos of some construction details - as can be seen, they are similar to our test enclosure (one difference is seal material - here it is some sort of soft silicon foam, Hammond provides us with much harder silicon gasket).

| {gallery}Z74 details |

|---|

|

Z74 seal |

|

Z74 detail |

And our star - Hammond 1554VA enclosure (a.k.a. DUT). Rated at IP68, with 6 self-captivating screws, threaded metal bushings, silicone gasket, made from UV resistant polycarbonate and designed for outdoor use. So - the best parameters in the family: models made from ABS are IP66 rated and enclosures of this size but with only 4 screws are only NEMA 4/4X (as discussed on the forum).

Connectors.

Amphenol RF and Amphenol CS provided us with extensive set of connectors to use in our projects.

As the connectors are from different families, we need to summarize their parameters to correctly plan our tests. Below there is information about six of them I have decided to install.

Amphenol RF states: "Amphenol RF alwyas identifies the IP rating in the unmated condition unless othervise stated", I haven't found such a default declaration for Amphenol CS products, so I have gathered this information from datasheets of the products.

| Connector | Datasheet | IP rating | Notes |

| N-Type Jack to SMA Jack Adapter 50 Ohm Straight Bulkhead IP68 | https://www.amphenolrf.com/242125-10.html | IP68 | in unmated condition |

| SMA Jack to MCX Jack Adapter 50 Ohm Straight IP67 | https://www.amphenolrf.com/ad-smajmcxj-1.html | IP67 | in unmated condition |

| TNC Straight Crimp Jack RG-174 RG-188 RG-316 Times LMR-100A Bulkhead Rear Mount 50 Ohm IP67 | https://www.amphenolrf.com/122192-15.html | IP67 | in unmated condition |

| MRJR series RJ45 connector | https://www.amphenol-cs.com/media/wysiwyg/files/documentation/datasheet/inputoutput/io_harsh_mrjr.pdf | ENVIRONMENTAL PERFORMANCE PER IEC 60529 CODE IP67 FOR SEAL BETWEEN MATING AREA AND PCB SIDE OF CONNECTOR. GASKET PROVIDES SEAL TO INSIDE FACE OF PANEL. |

|

| MRD series circular connector | https://www.amphenol-cs.com/product-series/rugged-mrd-circular-locking.html | IP67 | in mated condition (but has rubber cover builtin) |

| MRU series USB connector | https://www.amphenol-cs.com/product-series/rugged-mru-usb-2-0.html | IP67 | no information about mated condition requirement (as it was clearly stated for MRD connector) |

Based on this information, our Hammond enclosure with all the above connectors installed should be at least IP67 (with MRD connector covered by builtin cover). So - let's see...

Immersion test

Connector installation was not as straightforward as I hoped, but the main obstacle was PCB guide in the place of one of installation holes (previously reported by two of the other challengers) that had to be partially removed to make flat surface below connector seal/gasket

But after installation immersion test was successful - no bubbles, no water leakage visible. Photos below show enclosure after about 1-2 minutes of immersion (inside of the enclosure was dry after the test):

| {gallery}Immersion test |

|---|

|

Immersion test overview |

|

Immersion test detail |

|

Immersion test detail 2 |

As can be seen - short immersion is possible without any additional connector covers.

Side note to colleagues building water-related projects - our enclosure has high buoyancy (some force was needed to keep it submerged) and will probably tend to float without additional weight installed.