I want to use a Flex sensor to control the stepper motor based on the bending of the finger. A flex sensor is a low-cost, easy-to-use variable resistor that is designed to measure the amount of deflection it experiences when bent. The sensor's resistance is lowest when it's straight or flat on the surface, increases when we bend it slowly and reaches its maximum when it's at a 90-degree angle. Due to it's size a flex sensor can be easily attached with the finger to measure the bending of the finger.

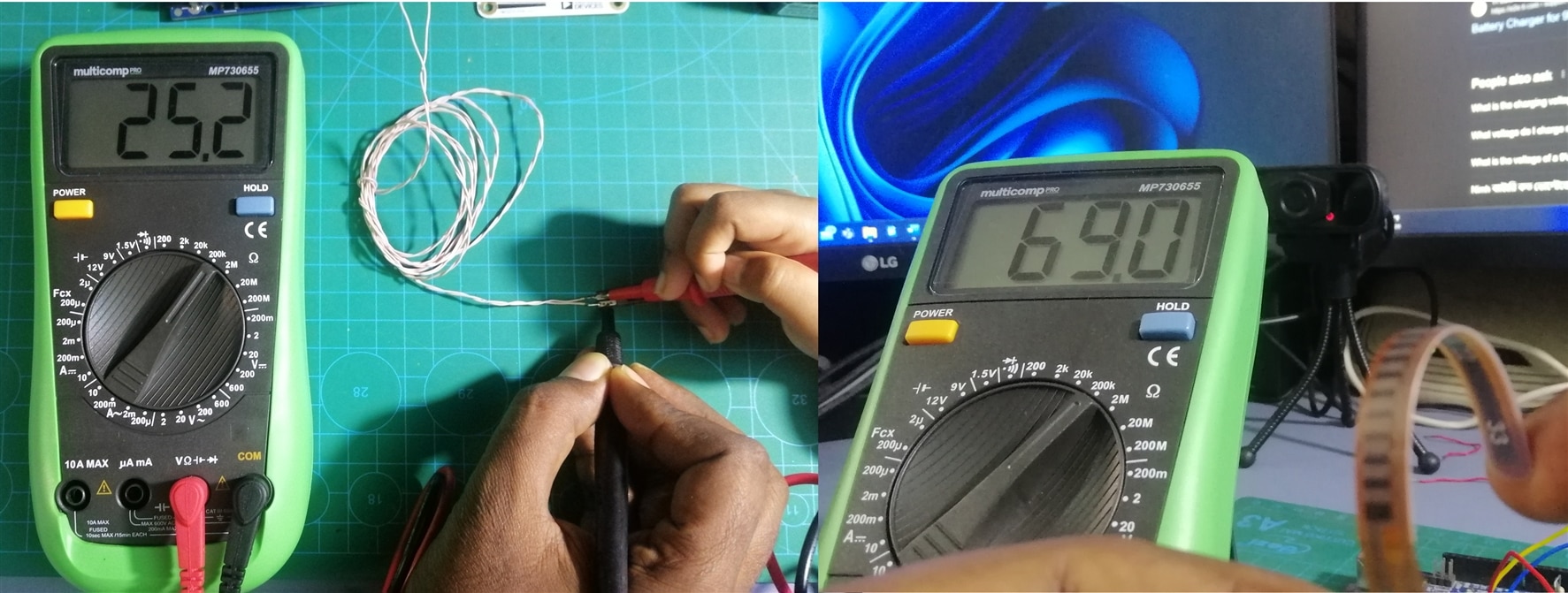

As already said, a flex sensor is a variable resistor that varies its resistance upon bending. As the resistance of the sensor is directly proportional to the amount of bending, it's often called Flexible potentiometer. This sensor is commonly available in two sizes, the first is 2.2” and the second one is 4.5” long. I am using the 2.2 inch flex for my project. When the sensor is straight the resistance is about 25K, and when the sensor is bent the value is 69K. As flex sensor is a resistor we must convert the resistance to voltage to read it using MCU. To get a proportional voltage to the sensor we need to make a voltage divider circuit attaching a fixed resistor in series with the sensor as shown in the animated image below. Based on the bending the resistance of the sensor changes and the output voltage also changes accordingly.

The image was taken from circuitdigest.com

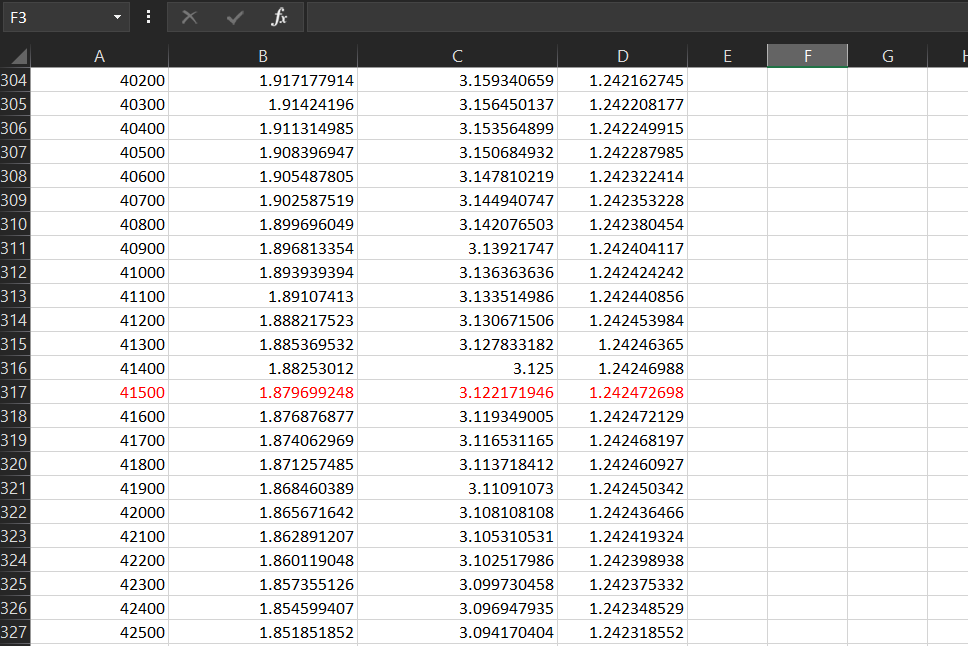

The sensitivity of the sensor depends on the value of the fixed resistor connected with the flex sensor. For calculating the exact value for maximum sensitivity first I measured the resistance of the sensor when it is straight and when it is bent at 90 degree. Then I calculate the resistance for getting the maximum variation in the output volage using Microsoft Excel.

I got the maximum sensitivity for the resistance of 41.5K. So, I planned to placed a 50K trim pot and set it to 41.5K and then connect it in series with the Flex sensor to get the maximum sensitivity. But for testing I connected one 20K and one 22K resistor in series for getting an approximate output. I used the following code for running the motor based on the bending.

/*******************************************************************************

* Copyright © 2023 Analog Devices Inc. All Rights Reserved.

* This software is proprietary to Analog Devices, Inc. and its licensors.

*******************************************************************************/

#include <SPI.h>

extern "C" {

#include "TMC5272_register_map.h"

#include "tmc5272.h"

}

/*

* Arduino Pins Eval Board Pins

* 51 MOSI 32 SPI1_SDI

* 50 MISO 33 SPI1_SDO

* 52 SCK 31 SPI1_SCK

* 53 SS 30 SPI1_CSN

* GND 23 CLK16 -> use internal

* 23 DIO 19 nSleep

* GND 2 GND

* +5V 5 +5V_USB

* 27 iRefR2 35 IREF_R2

* 29 iRefR3 36 IRREF_R3

* 31 uartMode 20 USEL/ for uart mode it should be HIGH

*/

#define IC_ID 0

int nSleep = 23;

int iRefR2 = 27;

int iRefR3 = 29;

int uartMode = 31;

void tmc5272_readWriteSPI(uint16_t icID, uint8_t *data, size_t dataLength) {

digitalWrite(PIN_SPI_SS, LOW);

delayMicroseconds(10);

for (uint32_t i = 0; i < dataLength; i++) {

data[i] = SPI.transfer(data[i]);

Serial.println(data[i]);

}

delayMicroseconds(10);

digitalWrite(PIN_SPI_SS, HIGH);

}

int previous_value;

void setup() {

Serial.begin(115200);

// put your setup code here, to run once:

pinMode(PIN_SPI_SS, OUTPUT);

pinMode(nSleep, OUTPUT);

pinMode(iRefR2, OUTPUT);

pinMode(iRefR3, OUTPUT);

pinMode(uartMode, OUTPUT);

digitalWrite(PIN_SPI_SS, HIGH);

digitalWrite(nSleep, LOW); // Disabling standby

digitalWrite(iRefR2, LOW);

digitalWrite(iRefR3, LOW);

digitalWrite(uartMode, LOW);

SPI.begin();

SPI.beginTransaction(SPISettings(500000, MSBFIRST, SPI_MODE3));

delay(10);

//set resistance to 10K

digitalWrite(iRefR2, HIGH);

digitalWrite(iRefR3, HIGH);

initMotorOne(IC_ID);

tmc5272_writeRegister(IC_ID, TMC5272_RAMPMODE, 0x0); //set position mode

tmc5272_writeRegister(IC_ID, TMC5272_VSTART(0), 0); //set maximum valocity

tmc5272_writeRegister(IC_ID, TMC5272_VSTOP(0), 10); //set maximum valocity

tmc5272_writeRegister(IC_ID, TMC5272_TVMAX(0), 0); //disable jerk reduction

tmc5272_writeRegister(IC_ID, TMC5272_AMAX(0), 50000); //set maximum acceleration

tmc5272_writeRegister(IC_ID, TMC5272_VMAX(0), 100000); //set maximum valocity

tmc5272_writeRegister(IC_ID, TMC5272_DMAX(0), 1000); //set maximum deacceleration

tmc5272_writeRegister(IC_ID, TMC5272_D2(0), 1);

tmc5272_writeRegister(IC_ID, TMC5272_XACTUAL(0), 0); //clear actual position

previous_value = analogRead(A0);

}

void loop() {

int sensor_value = analogRead(A0);

int diff = abs(sensor_value - previous_value);

if(diff>30)

tmc5272_writeRegister(IC_ID, TMC5272_XTARGET(0), sensor_value*10000); //set a target position

previous_value = sensor_value;

Serial.println(sensor_value);

delay(15);

}

Watch the demo video below: