Posts in this project

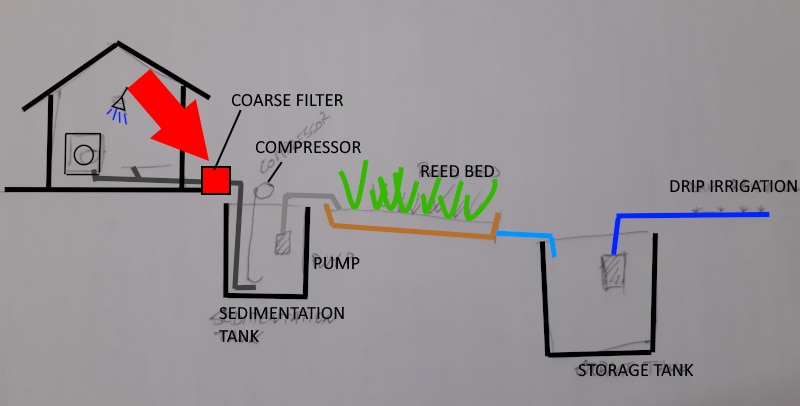

AquaFlow - Blog #1 - Introduction

AquaFlow - Blog #2 - The coarse filter

AquaFlow - Blog #3 - The sedimentation tank

AquaFlow - Blog #4 - The reed bed

AquaFlow - Blog #5 - The storage tank

AquaFlow - Blog #6 - Conclusions

The coarse filter

The most common type of coarse filter is gravel filter. Gravel filters don’t decontaminate water, they just remove suspended solid particles.

The action of removing suspended solid particles is defined as screening.

Particular kind of screening filters are granular media filters, commonly known as sand filters, in which feed water permeates through a bed of granular media such as gravel, sand etc. These are one of the oldest types of filtration, dating back millennia.

Despite their simple construction, sand filters work on five different principles:

- Direct collision; the interstices between the grains create a web-like network which uses physical straining to retain particles. The mesh size obtained strongly depends on the shape of the grains but is typically of at least an order of magnitude smaller than the grains themselves.

- Van der Waals forces; most filtering media are composed of polar substances. This facilitates the adhesion of polar substances on their surfaces.

- Surface charge attraction; some fine filtering media have a weak Z potential which attracts suspended particles of opposite charge.

- Diffusion; suspended particles tend to diffuse into the media due to random motion and thus to be eventually captured by one of the other processes.

- Hydrodynamic capture; due to hydrodynamic drag water flows slower in the immediate proximity of a filtering media chip than at a distance. A fine particle floating beside this chip will thus experience a faster flow on the far side compared to the near side which will cause it to spin (note that for microscopic particles, water’s perceived viscosity is much higher). This spin creates a motion force (Magnus effect) that causes the particle to move toward the chip. This increases the probability of small particles to be captured.

The combined effect of these mechanisms make granular media filters a surprisingly cheap and efficient solution to filter large quantities of water and is thus widely used in municipal water and well water treatment.

The best that you can do with sand filters is about 5 µm, so they are unable to remove ions, organic or chemical contaminants, heavy metals, pathogens etc., but can remove all particles visible with the naked eye. They are perfect to prepare the water for future treatment.

I built the sand filter from a 5-litres bucket. I drilled an inlet hole for the greywater in the top part and an outlet hole in the bottom part. Many small holes have been drilled in the outlet hose to let water drip.

I inserted the outlet hose in the hole and covered it with a fine mesh to capture debris and filled half of the bucket with volcanic stones. Thanks to the micro-cavities, volcanic stones creates a further barrier to debris.

In the top half of the bucket, there is 3D-printed drum.

The drum (which can be easily removed for cleaning) is lined with non-woven fabric. The basket is then filled up with small-grained sand. The amount of sand must be calibrated in order not to slow down too much the water flow.

And this is the assembled coarse filter

I’m sorry that this post has no electronic-related contents, but in the next post (where I will write about the sedimentation tank), things will be better!

References