Thge project so far:

The project so far:

Blog One – In the Air Tonight Project Start

Blog Two– In the Air Tonight, unboxing, connecting and first try outs

Blog Three– In the Air Tonight, Design, Parameters and a Plan! <-- this blog

Coming next: blog four - the build

Coming : blog 5 - extending and stretch objectives

Design Considerations:

I know that I will use an Arduino, Uno or Pro as my "base". Having had a rummage about I have found the Grove Sensor Shield for the Arduino Uno which lets you work with 3.3 and 5v inputs. - foot print size consideration

I know that if I do that I can use USB power for connecting up to desktop and programming, then can use the 9v line inut for power. - foot print and power consideration

I know that I will use the MQ series of gas sensors in addition to the challenge sensors as these are used for detection of other gases / pollutants, are inexpensive, they last and for my purposes where a relative reading is required, will do the trick. Having asked myself do i need to know with a high level of confidence the PPM for air bourne pollutants in my office breathing space, I think asides from propane/butane and carbon monoxide detection, probably not. foot print and power consideration

I know that if I use the MQ gas sensors that I am going to want to seperate the power channels from the DO / AO else these will draw too much from the Arduino - foot print and power consideration

I know that I need to decide on what MQ sensors to use and must remember that they get hot! foot print and power consideration

I know that I am going to use the laser dust sensor which will give me a dust concentration in the air for particles between 0.2 - 10 micro meters I must remember this also gets hot. foot print and power consideration

I will eventually want to log the data coming from this, but until I have a new raspberry pi in hand I want to have a display on my solution which provdies a VISUAL alert and AUDITORY alerts on my air qualty.

Bonus thought - find the project about the coal mine canary! Have a bird - dead of alive as part of the design. Yes Yes I like this.

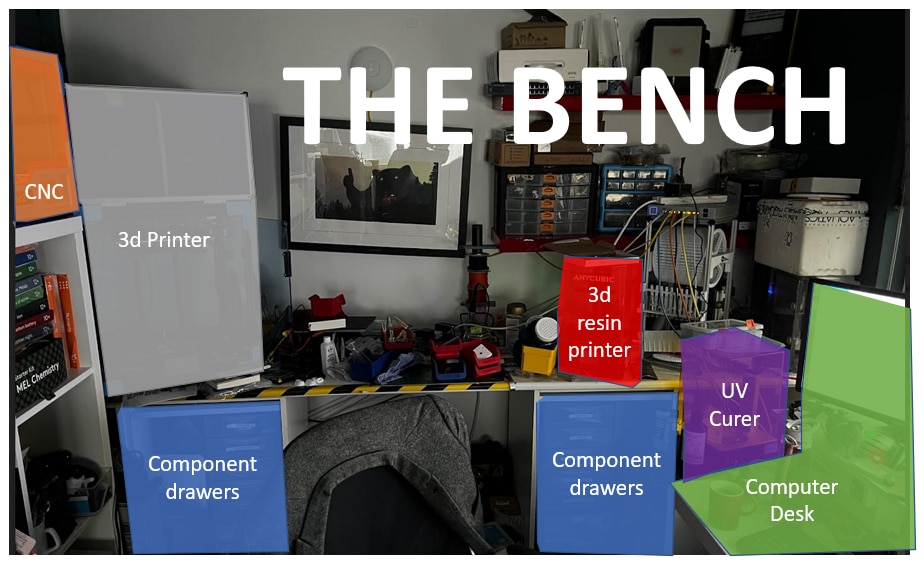

I know that I would like to have my sensor on my bench. I think I can go to a max base footprint of 250mm x 250mm and head clearance of up to 300mm before it needs more of a bench reorganisation.

My bench, next to my desk now looks a bit like this. (no judgement, i am decorating)

Parameters

MQ Series Gas Sensors.

I think as i mentioned previously, these are cheap and cheerful for what they do, a quick overview gives you:

- MQ-2: for combustible gas, detection concentration:

- MQ-3: for ethanol steam.

- MQ-4: for methane, natural gas.

- MQ-5: for home/industrial on LPG, natural gas, coal gas monitoring devices.

- MQ-6: for home/industrial on LPG (liquefied petroleum gas), butane, propane, LNG (liquefied natural gas) detection devices, excellent resistance to ethanol vapor, smoke interference.

- MQ-7: for home carbon monoxide detection device environment, suitable for carbon monoxide and gas detection.

- MQ-8: for home/industrial hydrogen leak on a monitoring device. It is not subject to ethanol vapor, soot, carbon monoxide and other gases interference.

- MQ-9: for home/industrial gas leak detection device, suitable for carbon monoxide, combustible gas monitoring device, test carbon monoxide: (CO) 10-1000ppm, combustible gas range: 100-10000ppm. Warm up time: more than 48 hours.

- MQ-135: for clean air, low conductivity tin dioxide (SnO2). Warm up time: more than 48 hours.

These are MOS or Metal Oxide Semiconductor type Gas Sensor which are also known as Chemiresistor. Esentially the sensor material resistance changes when it comes into contact with a gas, this changes inline with concentrations of that gas, allowing you to get a measure of how much is there.

Looking aty the MQ2 for example It can used to detect LPG, Smoke, Alcohol, Propane, Hydrogen, Methane and Carbon Monoxide concentrations in the air. Other specs:

- Operating Voltage: 5V

- Load Resistance: 20 kΩ

- Heater Resistance: 33Ω ± 5%

- Heating consumption: <800mW

- Sensing Resistance: 10 kΩ – 60 kΩ

- Concentration Scope: 200 – 10000ppm

- Bake in Time: Over 24 hours

But I am not going use all 9, nope. I settled on:

- MQ-2: for combustible gas, detection concentration:

- MQ-6: for home/industrial on LPG (liquefied petroleum gas), butane, propane, LNG (liquefied natural gas) detection devices, excellent resistance to ethanol vapor, smoke interference.

- MQ-9: for home/industrial gas leak detection device, suitable for carbon monoxide, combustible gas monitoring device, test carbon monoxide: (CO) 10-1000ppm, combustible gas range: 100-10000ppm. Warm up time: more than 48 hours.

- MQ-135: for clean air, low conductivity tin dioxide (SnO2). Warm up time: more than 48 hours.

which broadly covers the sorts of gas in the air you might expect on my office.

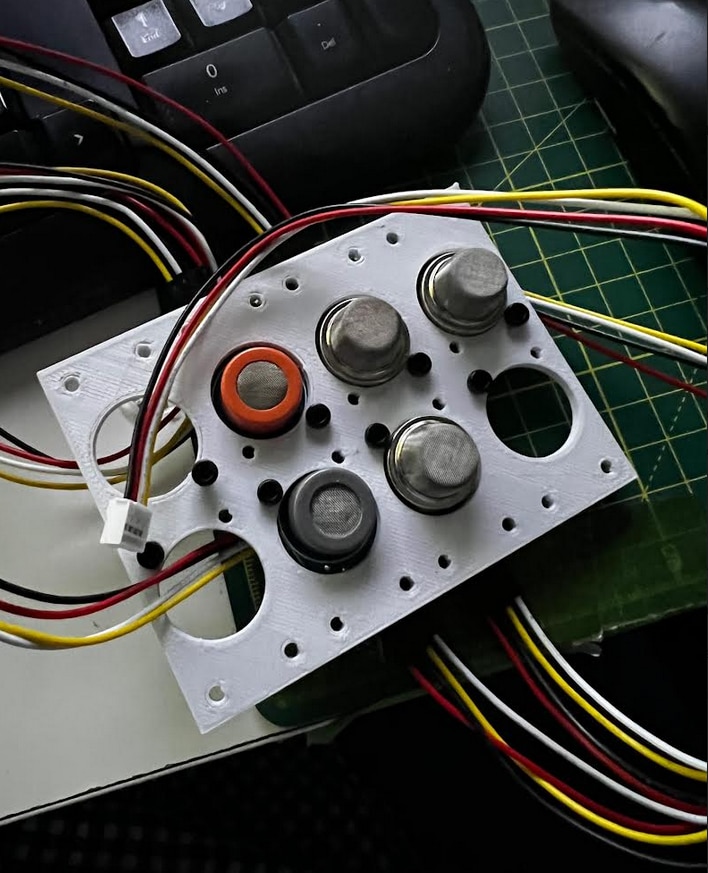

Now you may wonder how did you come to this conclusion! ? well I can tell you, by scientific method. I made myself this little test rig whcih had MQ 2, 3, 4,5,6,8,9 and 135.

and I left this on and logging using the Arduino UNO, with grove sensor shield, and a cheeky little wiring harness from a 5v buck to drive the sensors. I then went about a few days normal activity to which which, if any of the sensors got a measure on me. Would you believe it, but

- MQ-2: for combustible gas, detection concentration:

- MQ-6: for home/industrial on LPG (liquefied petroleum gas), butane, propane, LNG (liquefied natural gas) detection devices, excellent resistance to ethanol vapor, smoke interference.

- MQ-9: for home/industrial gas leak detection device, suitable for carbon monoxide, combustible gas monitoring device, test carbon monoxide: (CO) 10-1000ppm, combustible gas range: 100-10000ppm. Warm up time: more than 48 hours.

- MQ-135: for clean air, low conductivity tin dioxide (SnO2). Warm up time: more than 48 hours.

showed the most and vaired readings over the duration.

Activites engaged in included

- Normal days work at desk and computer

- Filament 3D printing, with PLA, ABS and a VERY stinky carbon fibre filament.

- Resin 3D printing, with the non water based stuff.

- My office gas heater on

- Some clearning up, including wiping and santifising surfaces, some hoovering

- The continued presence of my dog, with really quite a nasty bout of wind.

I knew these were to be my AQ sensor choice.

The Plan

Taking into account the design and paramter considerations we have gone from ,, ooh some post :D to some reading, thought about what does it need to do, then the how shall we do it, which leads from function to .... form.

Functional requirements

-4No MOS MQ gas sensors

-Dust sensor

-LCD / RGB display

-Alarm

5v power supply for MOS and dust

Form requirements

- Max foot print 250 * 250 * 300mm (all dims in mm unless otherwise specified)

- 3D design and printed, unless other suitable "thing" already exists and I have to hand (nope)

- 3D design in Fusion 360 (free for tinkerers and non commercial use)

- IT HAS TO BE USEFUL BUT HAVE SOME FUN ABOUT IT

I ended up with something like this: