It has been a very hectic week including a softball tournament on the weekend, but I did manage to squeeze in some work on calibrating my gas sensor module which is based on the TI MSP EXP432P401R launchpad.

The 18 turn offset and gain pots on my custom sensor card make it easy to adjust the sensor outputs to fit any two point calibration. If linearization is needed, it would be done in software, however I don't have a way to map such curves yet.

All sensors have been zeroed and the CO2 sensor is calibrated. The following video demonstrates the alcohol sensor, the CO2 sensor and the UV sensor in action. The other 2 sensors are also working in the video, I just wasn't blowing any gasses specifically at them.

All gas sensors are setup to be quite sensitive, making it easy to detect when the gasses present stray away from normal concentrations. This does result in it being quite easy to make them reach the maximum ADC reading. The ADC inputs are protected from over-voltage by buffer amplifiers that have the same supply voltage as the EXP432P401R.

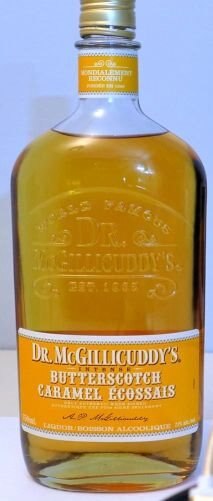

These tests were fun to do, partly because everything was working well and partly because I got to try a new liqueur - it is a new experience for me to have to drink to get data. Actually that isn't quite true - back in university I participated in blind testing to determine if people could determine domestic beer brands by taste alone. I couldn't, but it was fun trying.

This was just given to me for Father's Day, and it is the only alcohol in the house, so of course I "had" to use it for the alcohol tests.

The 3 MQx gas sensors work in sequence, one after the other to avoid having all heaters on at the same time. There is a yellow LED next to the sensor to indicate which heater is on. The heaters are on for 60 seconds, to evaporate and old gasses on the sensor element, and off for 120 seconds to allow the sensor element to cool off and start responding to new ambient gas concentrations.

The CO2 sensor is working great and it is the key gas sensor to audit air quality in my workplace. I'm not expecting any real nasty gasses at work.

Addendum - Office Air Quality Audit:

I took my gas sensor in to work today and wore it all day to audit air quality wherever I was.

I got lots of questions about the project and a few comments about Predator and other sci-fi shows.

In my office CO2 was about 420 ppm - the unoccupied areas were just under 400 ppm.

I was in a heavy duty meeting for 3.5 hours in the morning with 20 upper management staff. The CO2 levels rose to 780 ppm.

I had one other meeting in the afternoon for an hour with 5 staff. The CO2 levels rose from 400 to 550 ppm in one hour.

These levels aren't dangerous but I was surprised at how much people influenced the readings.

(How significant are people as greenhouse gas machines?  )

)

This project really has been a learning experience - with several interesting surprises.

This instrumentation and the accompanying research have already turned out to be very useful in so many ways - all the more reasons why I am glad I participated in this challenge.

All links to blogs related to this project can be found in the first blog here:

Safe and Sound - Invisible Hazardous Environmental Factors Monitoring System - blog 1

Top Comments

-

DAB

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

dougw

in reply to DAB

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

dougw

in reply to DAB

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children