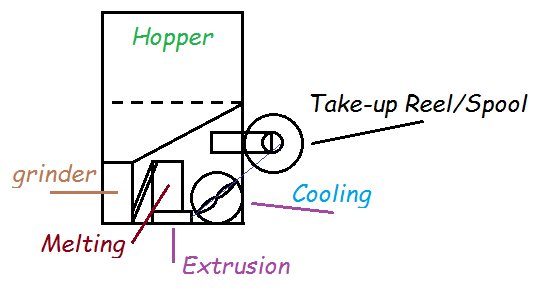

Enjoyed the video on the briefcase sized 3D Printer. How about a companion unit to make filament? Should be able to take suitably sized plastics, grind, extrude and roll onto spools, for use with the briefcase-sized 3D printer, making for a completely portable 3D factory. Simple menu selection (ie-soda bottles, milk jugs, cd cases, plastic bags, etc.) to set the temperature and extrusion/spooling speed.