If you have cured a resin 3d print before, you may have noticed that some resins take longer to cure than others, and they also react differently in various curing stations. Most of the commercially available devices just blast the part with broad spectrum UV and don't care how much energy they are using. In some extreme cases this energy builds up heat inside the 3d printed part which can lead to cracking. Clem is hunting for solution! Is there a perfect spectrum and intensity to allow each Resin to get the fastest curing time while using the least amount of energy? Which spectrum exactly is responsible for curing, and can we cut energy bills by just omitting any spectrum that doesn't help the process? To find out, Clem constructs a curing station with Würth Elektronik high precision UV leds and Magi³C Led Drivers!

The results were incomplete at the time of filming of the video so you can view them in the following writeup:

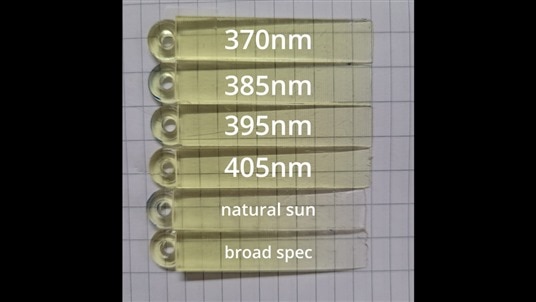

I have printed 5 samples for each spectrum and compared the curing results after 10 mins and 20 mins for each spectrum.

In comparison there is also a pic of a part cured 1hour in broad daylight, but that is not really comparable as the spectrum and power intake is not controlled.

Each sample got exposed to 700mA at 24V over 6 LEDs for each spectrum.

The comparison pictures are color graded to make the differences more pronounced.

Here are my initial findings:

Resin: MAYER MAKES Engineering Resin

Test: which spectrum is responsible for Curing

Test: is one of these specifically affecting the curing indicator(aka could it lead to false positives)

370 No effect noticeable (only curing due to unwanted activation of 405??)

385 very limited effect after 10 min (overlapping with 395 in spectrum)

395 part mostly cured, expected behavior.

405 part mostly cured, expected behavior.

The material is intended to be cured by UV light in the range of 395-405nm, which the test confirmed.

it also showed that UV range below this spectrum did not affect the curing process- > therefore these ranges would only waste energy.

The curing indicator faded after 20mins at 2mm, so we can derive an expected curing time of 10min/1mm @405nm

I suspect most of the indicator that faded in the 395nm test is due to overlap in spectrum at the high end.

Concluding that indeed 405nm is the spectrum that is responsible for the curing and decomposition of the indicator.

Thicker portions of course need longer exposure and this effect is non linear. we don't have long term tests under controlled conditions, but i expect the amount to be logarithmic in nature analogous to the fall of of light intensity when travelling through thick glass.

Supplemental Content:

- You can also download all the CAD, ECAD,and Code for this project for free: Episode 569 Resources

Bill of Material:

| Product Name | Manufacturer | Quantity | Buy Kit |

|---|---|---|---|

| "MEAN WELL AC/DC Power Supply | mean well | Buy Now | |

| "NANOTEC Stepper Motor | nanotec | Buy Now | |

| "TDK SMD Multilayer Ceramic Capacitor | TDK | Buy Now | |

| "ONSEMI Fixed LDO Voltage Regulator | onsemi | Buy Now | |

| "MULTICOMP USB Connector | multicomp pro | Buy Now | |

| "MULTICOMP PRO Heat Sink | multicomp pro | Buy Now | |

| "KYOCERA AVX SMD Multilayer Ceramic Capacitor | Kyocera | Buy Now | |

| "PRO POWER Tape | pro power | Buy Now | |

| "BOURNS Rotary Encoder | Bourns | Buy Now | |

| Würth Elektronik UV LED 370/365nm | Würth Elektronik | Buy Now | |

| Würth Elektronik UV LED 385nm | Würth Elektronik | Buy Now | |

| Würth Elektronik UV LED 395nm | Würth Elektronik | Buy Now | |

| Würth Elektronik UV LED 405nm | Würth Elektronik | Buy Now | |

| Würth Elektronik Led Driver magi³c Dev kit | Würth Elektronik | Buy Now | |

| Individual drivers not listed on Farnell yet. | Würth Elektronik | Buy Now | |

Additional Parts:

| Esp32S2-Wroom |

| Midas Oled from previous project. |

| TMC2208 stepstick |