Join us as we explore the harsh lessons learned from building a swarm of tiny robots powered by ATtiny416 microcontrollers, vibration motors, and 3V coin cells. What started as a simple DIY robotics project quickly descended into development hell plagued by power issues, motor driver failures, inconsistent components, and programming headaches. Follow along as we break down the seven circles of integration problems, uncover what went wrong, and share practical insights to help you avoid the same pitfalls in your own projects.

Watch the Disaster Unfold

The Seven Circles of Development Hell (And How to Escape Them)

Welcome to Development Hell—where hopes and dreams slowly wither away, crushed under the weight of endless debugging and integration nightmares. Also known as Integration Hell, this is the place where once-simple projects morph into chaotic labyrinths of uncertainty, inconsistency, and outright suffering.

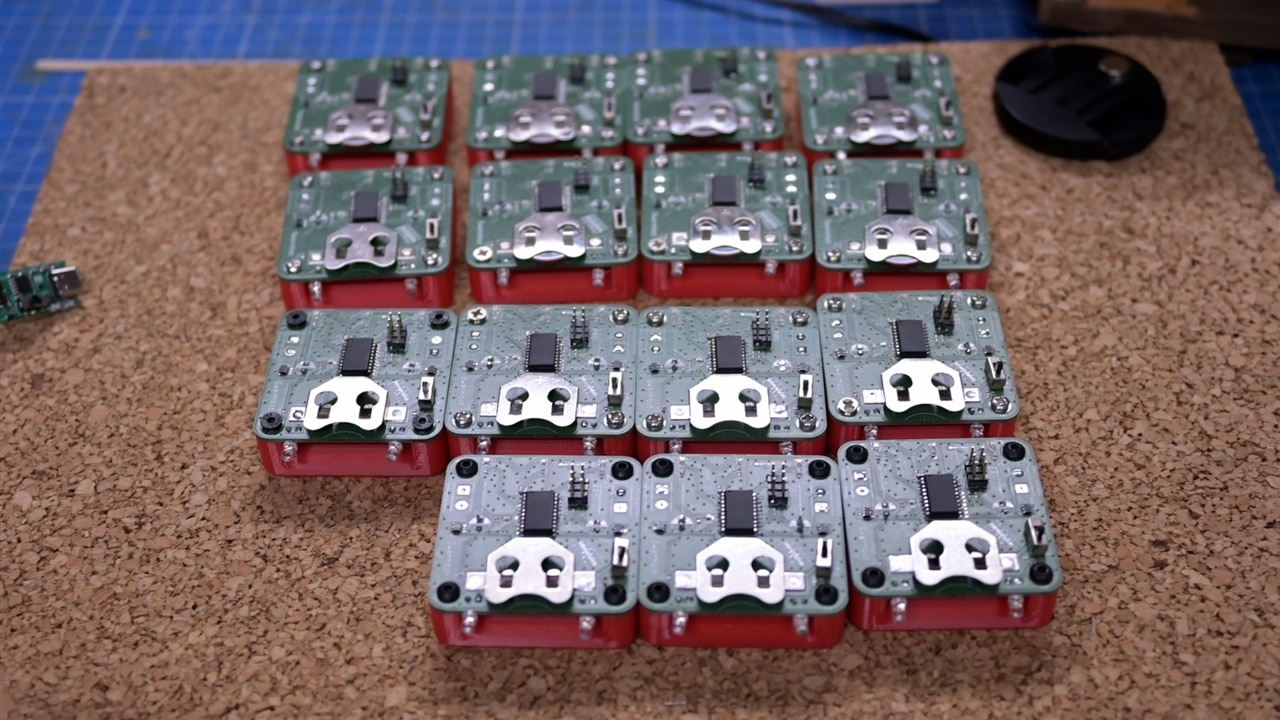

Many developers have experienced this descent firsthand. What begins as a straightforward idea—such as building a swarm of small robots that influence each other to create emergent behaviours—can quickly spiral into a seven-layer cake of misery. From hardware failures to programming pitfalls, every step of the process can present new challenges. However, understanding the circles of Development Hell can help navigate (and hopefully escape) them.

So, let’s take a tour of the seven circles of Development Hell and explore ways to return to productivity.

Circle 1: An Unfamiliar Platform

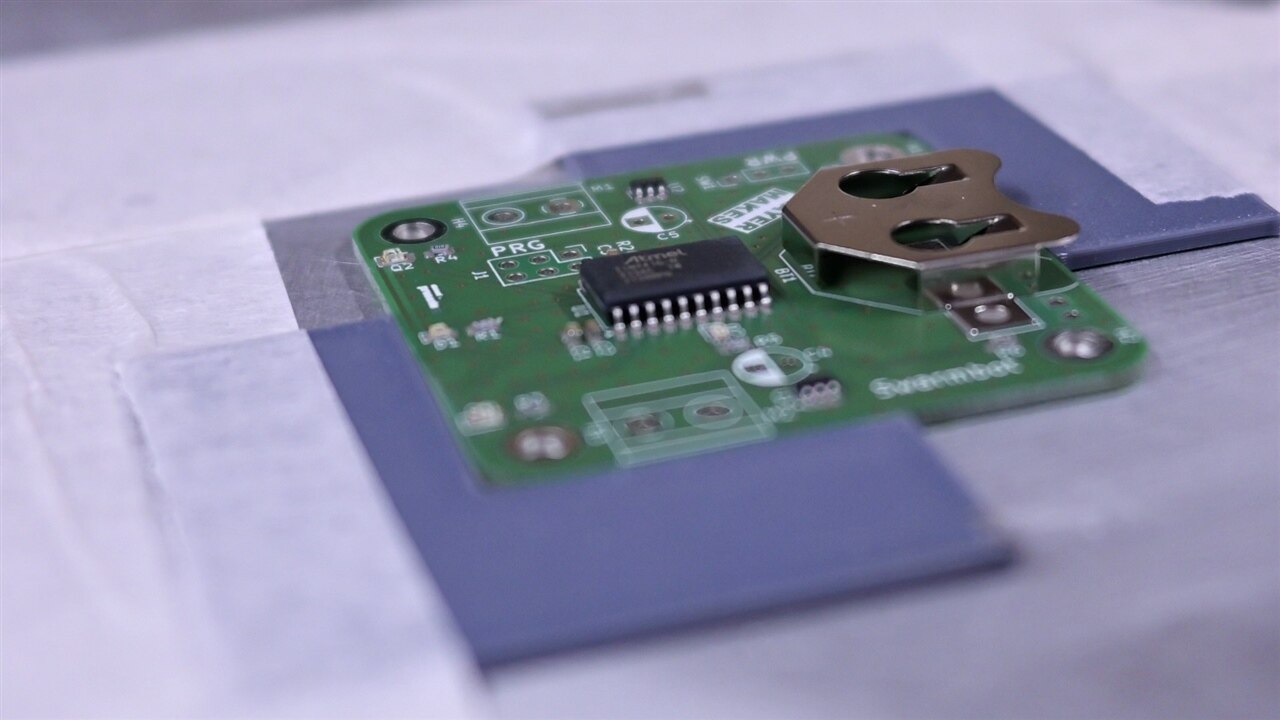

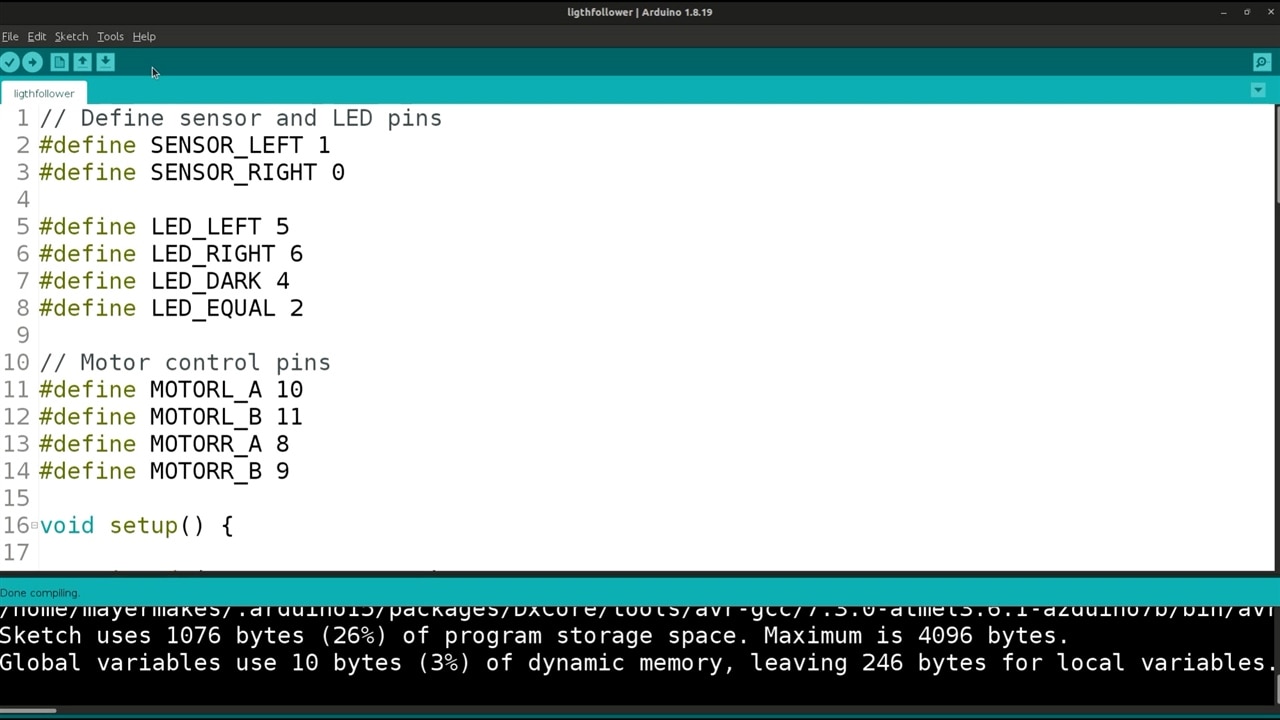

The Problem: Choosing a new platform often means wrestling with unfamiliar tools, cryptic documentation, and unexpected limitations. For instance, working with the Attiny 416 microcontroller requires a special UPDI programmer, specific toolchain configurations, and an outdated version of the Arduino IDE.

The Escape: Researching toolchains and compatibility before committing to a platform is crucial. Looking for active community support and testing simple setups before full adoption can prevent setbacks. If venturing into uncharted territory, allocating extra time for learning is advisable.

Circle 2: Unknown Components

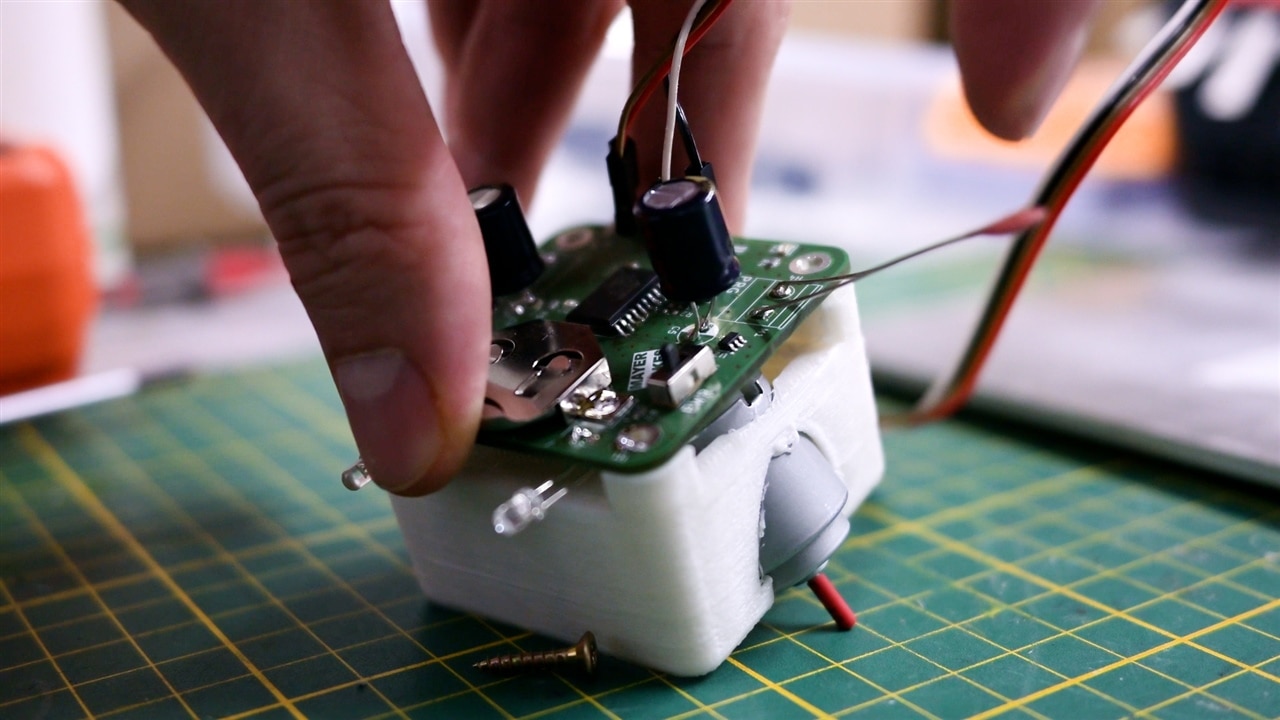

The Problem: Unfamiliar components introduce a host of new issues—ambiguous datasheets, conflicting specifications, and unexpected quirks. For example, dealing with MP6513 motor drivers, interpreting signals from unknown Würth photo-transistors, or troubleshooting unpredictable motors can create significant delays.

The Escape: Sticking with well-documented and widely used components whenever possible is a good practice. When obscure parts are necessary, consulting community forums, application notes, and example projects before committing can help mitigate risks. Prototyping and testing individual components early can prevent major surprises later.

Circle 3: Uncertain Goals

The Problem: A poorly defined objective leads to scope creep, inefficiency, and decision paralysis. A project might start with an emphasis on TinyML, inter-robot communication, or simply ensuring basic functionality, but shifting priorities can result in wasted effort and frustration.

The Escape: Defining a Minimum Viable Project (MVP) and adhering to it is essential. Clearly outlining success criteria before starting and avoiding secondary goals until primary objectives are met helps maintain focus. When uncertainty arises, validating ideas through small experiments before committing can save time and effort.

Circle 4: Time Constraints and Underestimations

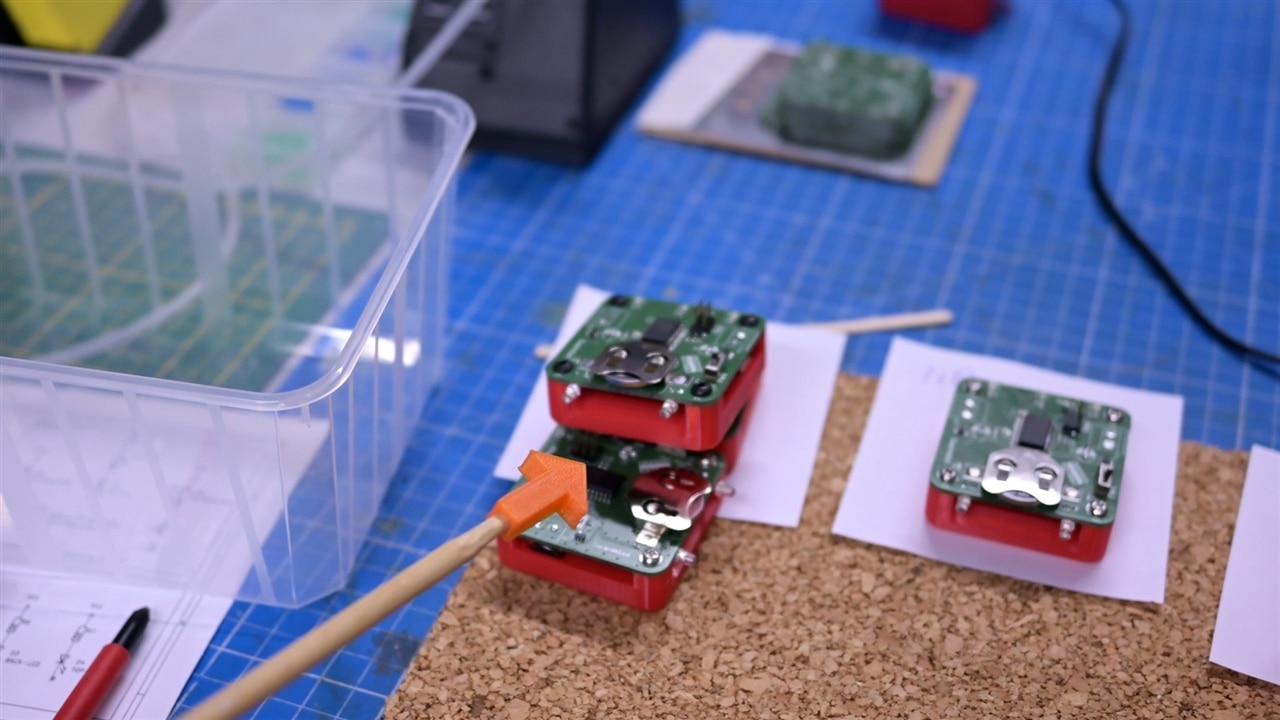

The Problem: Scaling a project beyond realistic expectations can lead to significant setbacks. For instance, building 25 robots might sound feasible—until the time required for assembly, testing, and troubleshooting becomes overwhelming.

The Escape: Breaking projects into smaller milestones with realistic estimates can prevent exhaustion. Considering automation or outsourcing for repetitive tasks can improve efficiency. If a timeline is slipping, removing non-essential features rather than forcing rushed work is often the best solution.

Circle 5: Manufacturing Inconsistency

The Problem: Even with the same PCB and components, results can vary. Some devices may have odd power consumption issues, while others suffer from unexplained motor noise.

The Escape: Expecting variability, especially in hardware projects, is essential. Using controlled test environments and maintaining detailed logs of behaviours can aid in troubleshooting. Sourcing components from the same batch and investigating alternative suppliers or design adjustments can also improve consistency.

Circle 6: Programming Hiccups

The Problem: Flaky flashing interfaces, cold solder joints, undefined behaviour, and brownouts are common obstacles. Debugging in such conditions can be slow and frustrating.

The Escape: Investing in proper debugging tools—such as logic analysers, oscilloscopes, and serial debuggers—can significantly ease troubleshooting. Implementing fail safes early, such as watchdogs and reset mechanisms, ensures stability. Version control and incremental testing prevent the accumulation of unresolved issues.

Circle 7: Issue Compounding and Project Mismatch

The Problem: When multiple issues stack up, frustration peaks. Goals shift, motivation drops, and the project starts to feel like a never-ending death march. In some cases, a project may end up vastly different from its original vision.

The Escape: Knowing when to pivot is important. Sometimes, the best outcome is learning from failure and moving forward. Many developers find that their struggles become valuable learning experiences, leading to better projects in the future. When a project feels doomed, reassessing the approach—or even letting go—can be the best course of action.

Redemption: There’s Always Another Project

The good news? Even after experiencing the seven circles of Development Hell, there is always another challenge waiting. Every difficult project offers valuable lessons, making the next one a little smoother.

For those lost in Integration Hell, documenting struggles, learning from them, and moving forward is the key to success.

Have you ever been through Development Hell? Share your horror stories (and survival tips) in the comments below!

Supporting Files and Links

- Make your own UPDI Programmer - UPDI Program for new ATTiny -- Episode 529

- Megatiny core: https://github.com/SpenceKonde/megaTinyCore

Bill of Materials

| Product Name | Manufacturer | Quantity | Buy Kit |

|---|---|---|---|

| ATTINY416-SN MCU, 8BIT, 20MHZ, SOIC-20 | microchip | 25 | Buy Now |

| MP000357 BATTERY HOLDER, 2032, SMD | Multicomp | 25 | Buy Now |

| MP6513GJ-Z MOTOR DRIVER | MP | 50 | Buy Now |

| CR2032 CELL, LITHIUM, CR2032, 210MAH, 3V | Multicomp | 25 | Buy Now |

| PEL00881 DC MOTOR, 3V | Pro elec | 50 | Buy Now |

| 1540801NBA300 PHOTOTRANSISTOR, 940NM, 0805 | Würth | 50 | Buy Now |

| ECA1CM101I CAP, 100UF, 16V, ALU ELEC, RADIAL | 50 | Buy Now | |

Additional Parts

| Product Name | Manufacturer | Quantity |

|---|---|---|

| UPDI Programmer | 1 |

Top Comments