In this episode, Milos transforms a $10 flea-market air fryer into a fully functional smart filament dryer using the Arduino Uno R4 WiFi. By connecting it to the Arduino Cloud, he can monitor temperature, control the heater and fan, and even receive notifications when drying is complete. Watch as he tackles the challenge of drying moisture-sensitive filaments like nylon and TPU, compares print results before and after, and shows how to safely build your own DIY IoT filament dryer.

Watch the Project Build

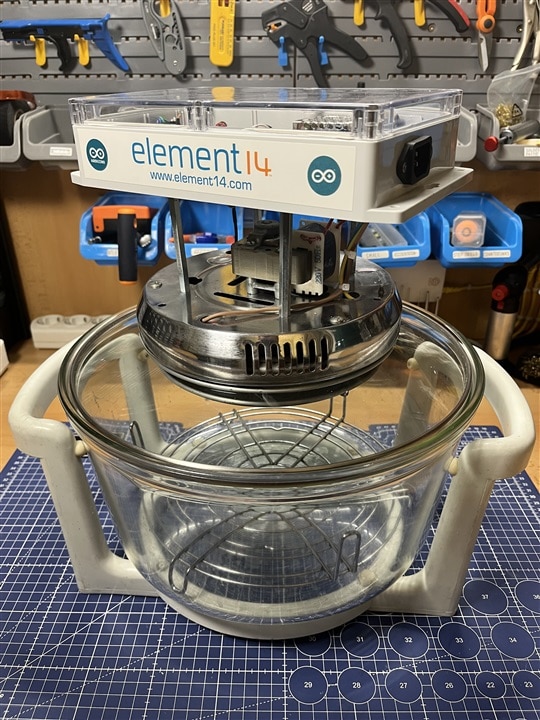

In this episode, Milos takes an old $10 air fryer he found at a local flea market and converts it into a fully functional smart filament dryer using an Arduino Uno R4 WiFi. The result is a low-cost, internet-connected dryer that can be controlled through a web dashboard or a mobile phone.

As Milos explains, “If you’ve watched any of my previous videos, you know I use a lot of 3D printing for my projects... But there are some other filaments that are quite more difficult, something like TPU or nylon. They get extremely wet and the printing quality just degrades rapidly.”

That problem inspired him to build a dryer that would make exotic filaments like nylon and TPU easier to work with.

The Idea

While filaments such as PLA and PETG can tolerate ambient humidity, others like nylon and TPU readily absorb moisture from the air, which can ruin print quality. Off-the-shelf filament dryers are available for around $50–$100, but Milos decided to make his own for a fraction of the cost.

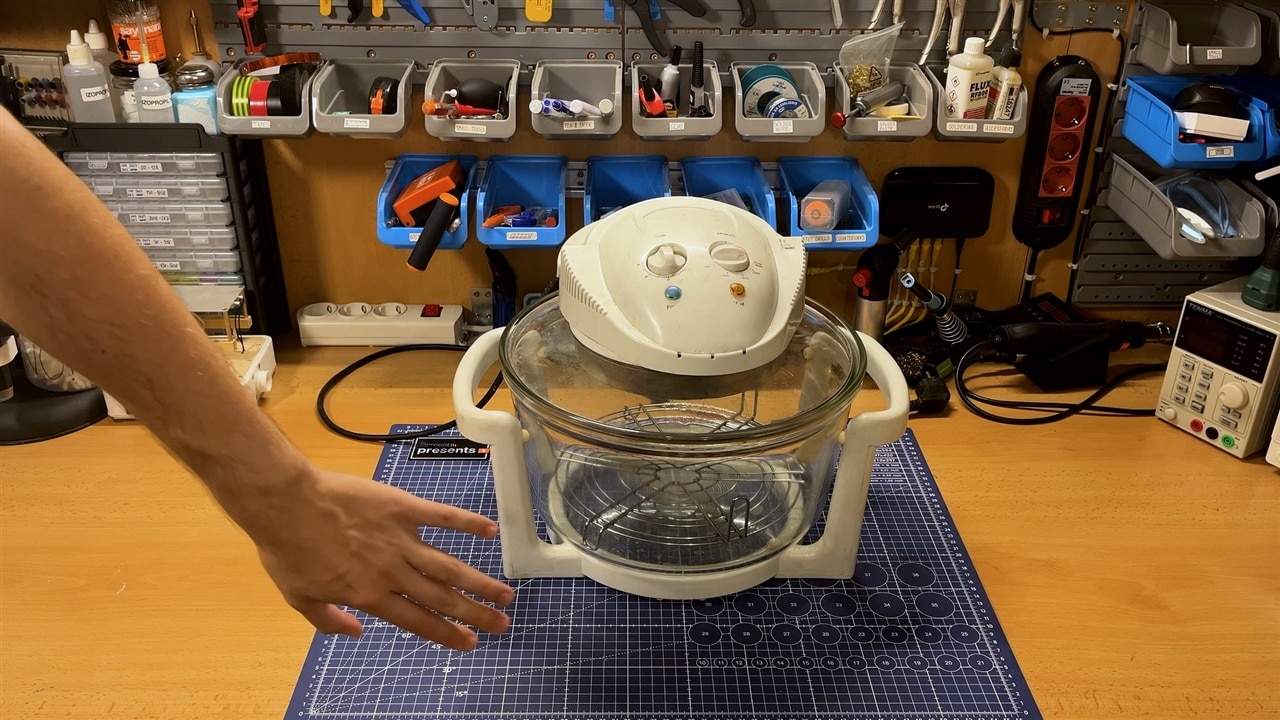

“For just ten bucks, I found this old air fryer at the flea market. I thought, why not convert it to a filament dryer and see what kind of results we could get?” he says in the video.

Design and Hardware

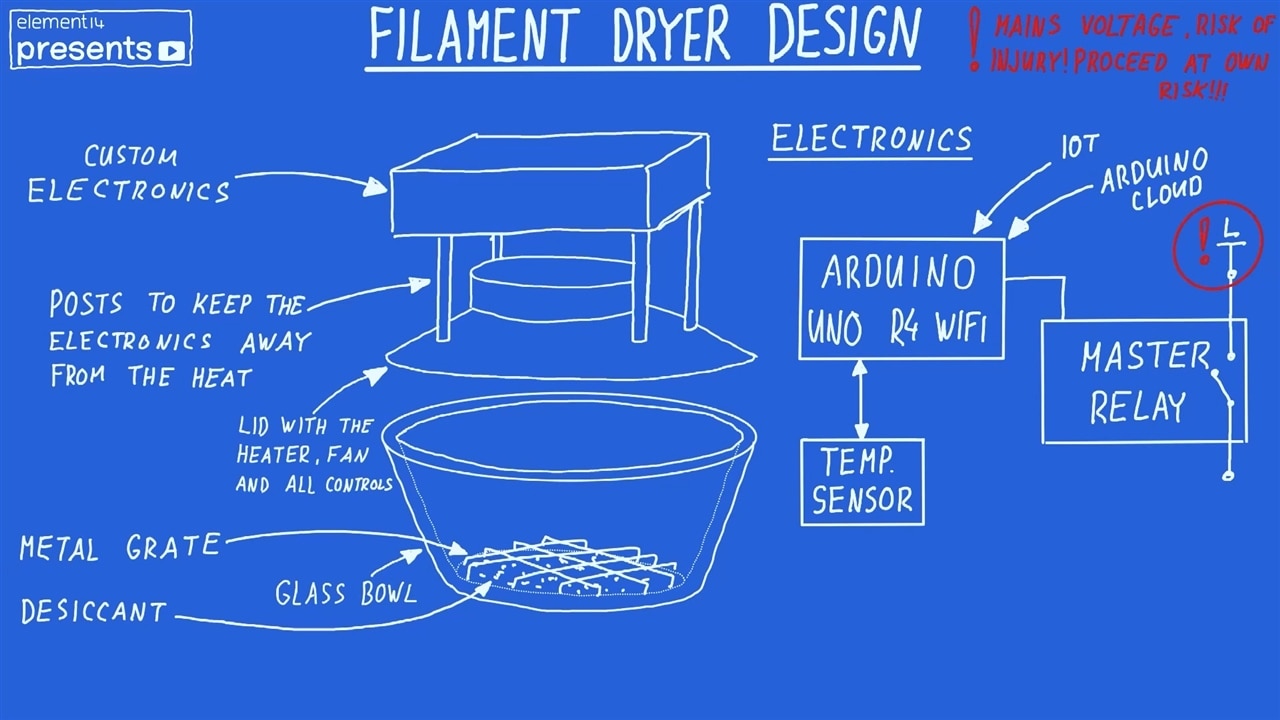

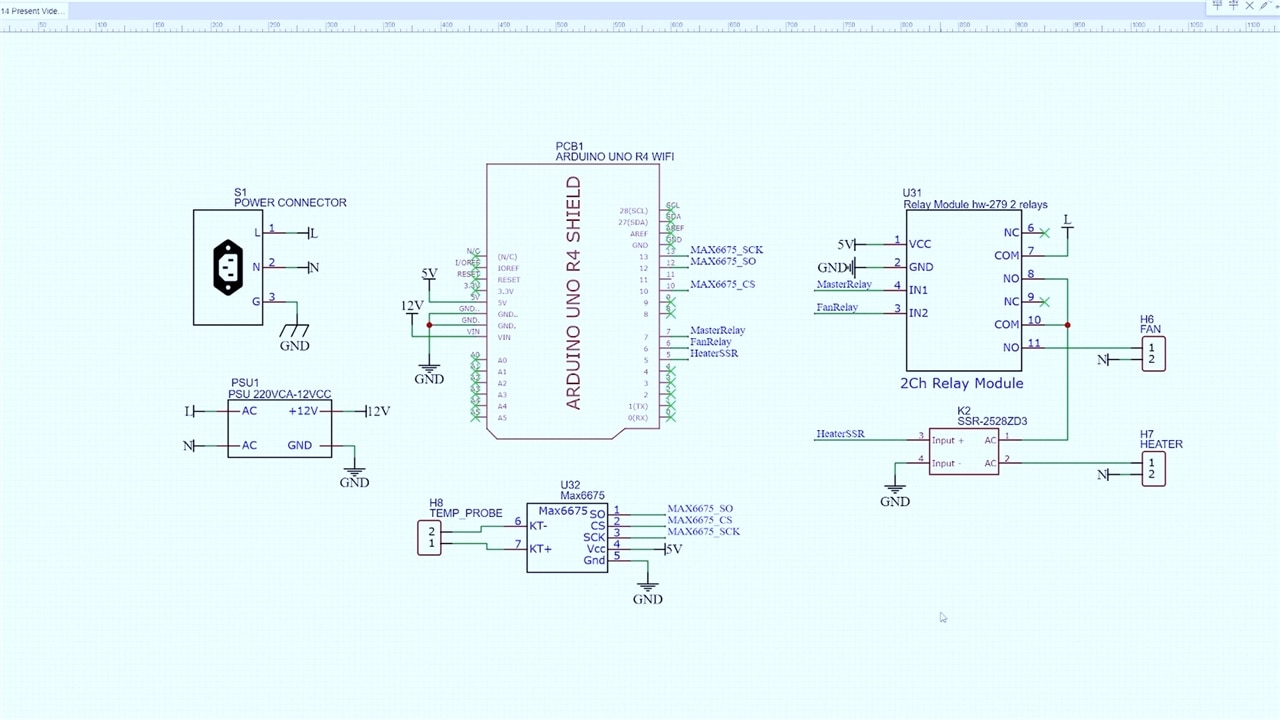

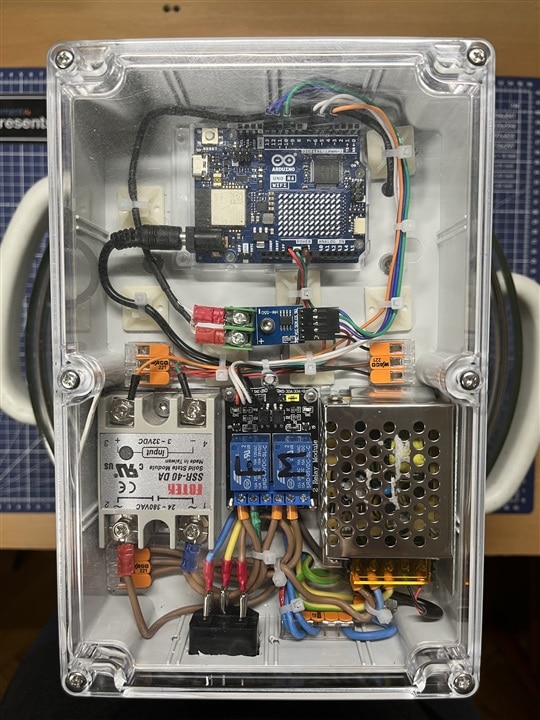

The air fryer consists of a glass bowl and a lid that houses the electronics — a metal fan and a heater. Milos’ plan was to remove the existing controls and replace them with custom electronics so that he could control both the fan and heater while monitoring temperature via a sensor.

He based the project around the Arduino Uno R4 WiFi, chosen for its processing power and built-in connectivity. “As the brain of this thing, I will be using an Arduino Uno R4 WiFi. I want to make this an IoT device and we are going to use Arduino Cloud since it will enable us to make a dashboard really easily,” he explains.

Note: Power and Safety - Mains Voltage

The project runs on mains voltage (220V in Milos’ case) and is powered via a 12V power supply for the Arduino. He implemented three relays for control and safety:

-

Master Relay: acts as a safety relay that powers the rest of the system.

-

Fan Relay: turns the air circulation fan on and off.

-

Heater SSR: a solid-state relay that controls the heater safely at higher switching frequencies.

As Milos warns, “This is a disclaimer. You’re going to be working here with mains voltage. If you want to recreate this, there is a risk of injury or death, so please be careful.”

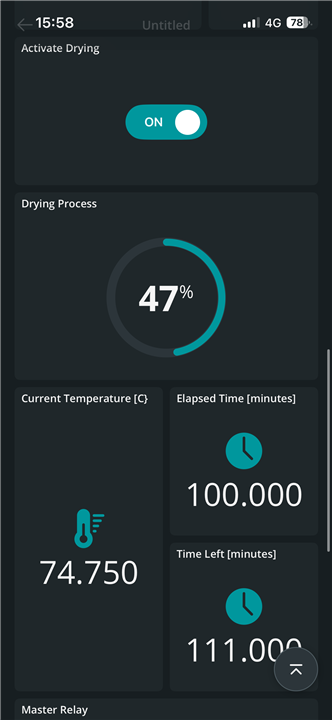

Software and IoT Dashboard

Using the Arduino Cloud, Milos developed the control software and monitoring interface for the filament dryer. This setup allowed him to program the Arduino Uno R4 WiFi online and manage it from any device. “Usually this would mean going to the Arduino IDE and programming the Arduino, but this time we are going to use the Arduino Cloud… It’s fully integrated with Arduino, so it’s pretty much plug and play with just minimal setup needed,” he explains.

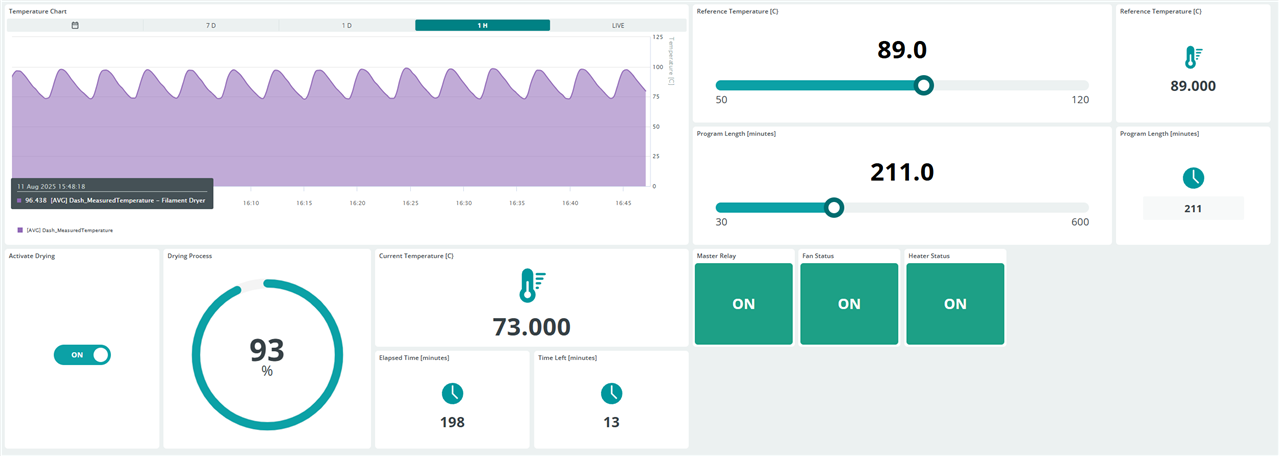

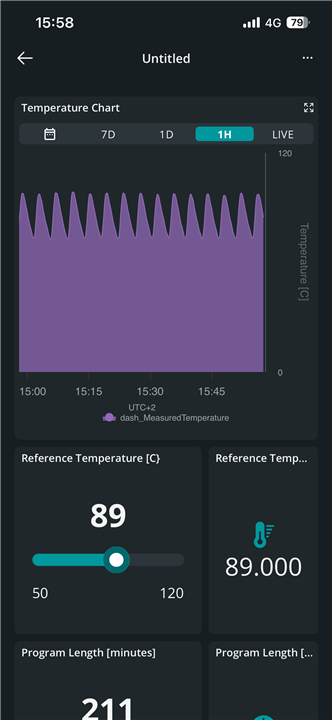

Within the Arduino Cloud interface, he configured the device by following the simple setup wizard and then created a “Thing” for the dryer. From there, he defined cloud variables that handle heater control, fan speed, temperature thresholds, and system states. “You can simply add cloud variables, choose whether they’re read or write, and then connect them to widgets in your dashboard,” Milos demonstrates.

He also highlighted how the dashboard was built entirely through a drag-and-drop interface. “You can see the live temperature now from the filament dryer that’s running currently… You can track your filament dryer when you’re not at home,” he says, showing both the desktop and mobile layouts.

An additional Arduino Cloud feature Milos used was Triggers, which send notifications when certain conditions are met. “When the drying process completes or if any error occurs, I get both an email and a push notification on my phone so that I can investigate what happened,” he notes. These alerts are generated automatically without any external integrations, adding a layer of convenience and safety to unattended drying cycles.

Safety and Error Handling

Given that the system runs on mains voltage and powers a 1kW heater, Milos incorporated multiple layers of hardware and software safety. On the hardware side, he used a master relay for total power control and a solid-state relay (SSR) for the heater to safely handle frequent switching. “If we for some reason want to kill the whole thing, we can just switch off the master relay and know that neither the fan relay nor the heater will get power,” he explains.

The software is designed with similar precautions. Milos added logic to detect sensor faults or abnormal readings. “If delta is more than five degrees, that means something’s wrong with the sensor, and we want to kill the whole thing since it’s working with a heater,” he explains. The system also shuts down if the measured temperature falls below 5°C or exceeds 150°C, ensuring it cannot run in an unsafe state.

These limits were determined through testing. “Even under a direct flame, the temperature only changes a degree or two between readings, so anything more indicates a fault,” he observed during sensor calibration. This combination of relay-based hardware protection and software-level monitoring ensures that the system remains stable and safe during long drying sessions.

Testing and Results

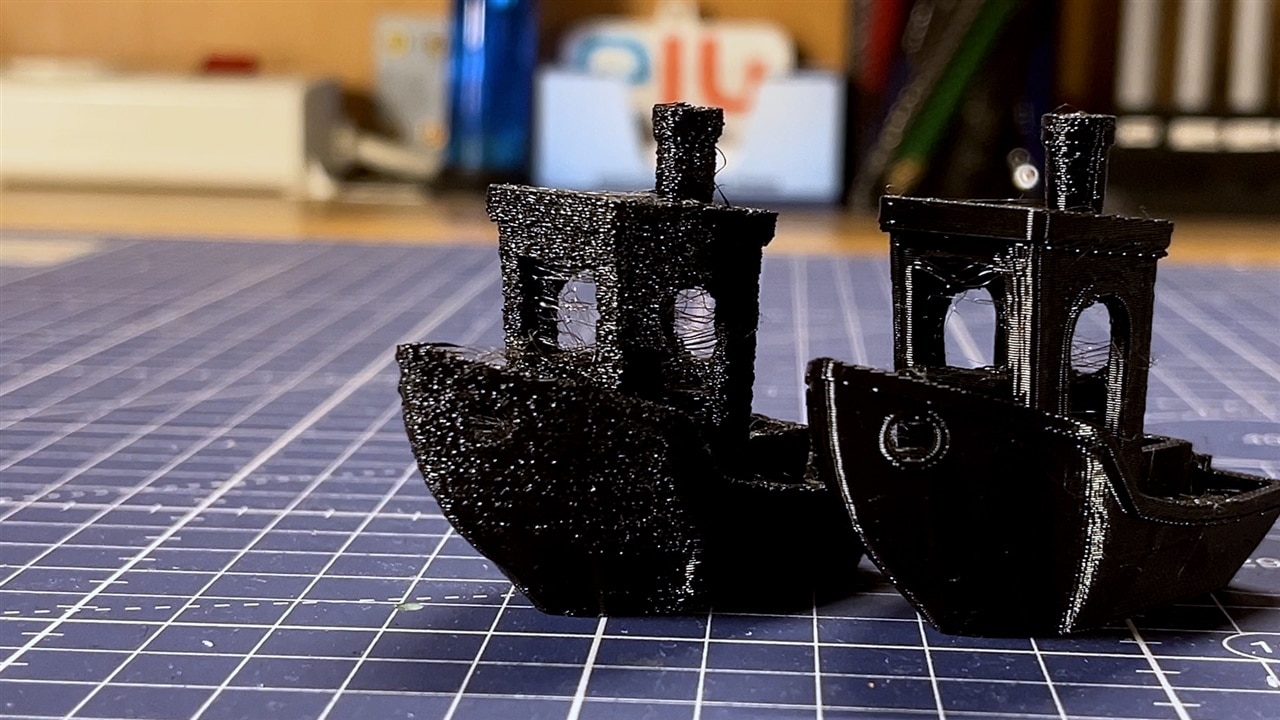

After completing assembly and programming, Milos began testing with two materials known for moisture sensitivity, nylon and TPU. “Finally, time to do some testing… For testing, I’m going to be using two different filaments, first nylon then TPU,” he says.

For nylon, he ran the dryer at approximately 90°C for about five hours, observing progress through the Arduino Cloud dashboard. “Everything worked great. I could check the graph on the dashboard and see the temperature in real time,” he explains.

The print results clearly showed the difference. “You can see that it doesn’t even look like the same filament — the dried one is whiter, cleaner, and the print quality is much better,” Milos says, showing side-by-side comparisons of a Voron cube and Benchy. The dried nylon printed smoothly, without bubbling or stringing.

TPU testing produced similar improvements. “It’s like night and day difference again… it looks so much better,” he says. The dryer’s steady temperature control and airflow restored both materials to a usable condition, producing visibly higher-quality prints. “This opens up the possibility to finally use nylon for functional prints like gears,” Milos adds, noting that the project significantly improved his 3D printing workflow.

Wrapping Up

Reflecting on the build, Milos describes the project as a complete success. “I think that this project was a really big success. It’s something that I’ll be using for sure for this kind of filaments and other exotic ones like PCF or polypropylene,” he says.

He again emphasises safety for anyone planning to replicate it: “Please be careful if you try recreating this, it works with mains voltage.”

Overall, he’s pleased with both the outcome and the process. “I’m really happy with how it turned out, the results are really good, both for nylon and TPU,” he concludes. The project demonstrates how low-cost components and thoughtful design can produce a practical, connected tool for makers who want better control over their 3D printing materials.

Supporting Links and Files

Bill of Materials

| Product Name | Manufacturer | Quantity | Buy Kit |

|---|---|---|---|

| Arduino Uno R4 WiFi - ABX00087 | ARDUINO | 1 | Buy Now |

| DFROBOT Temperature Sensor - DFR0558 | DFROBOT | 1 | Buy Now |

| Dual Relay Module - 103020132 | SEEED STUDIO | 1 | Buy Now |

| Solid State Relay - G3NA-205B-UTU DC5-24 | OMRON INDUSTRIAL AUTOMATION | 1 | Buy Now |

| 12V PSU - TXN 25-112 | TRACO POWER | 1 | Buy Now |

| Nylon Filament - MC011476 | MULTICOMP PRO | 1 | Buy Now |

Additional Parts

| Product Name | Manufacturer | Quantity |

|---|---|---|

| Old Air Fryer | ||

| K Type sensor with adapter PCB - Alternative provided in parts, needs code adjustment | ||

| Wires | ||

| Ferrules | ||

| WAGO Connectors | ||

| M4 Metal Posts | ||

| Polyflex HF TPU 95 |

Top Comments