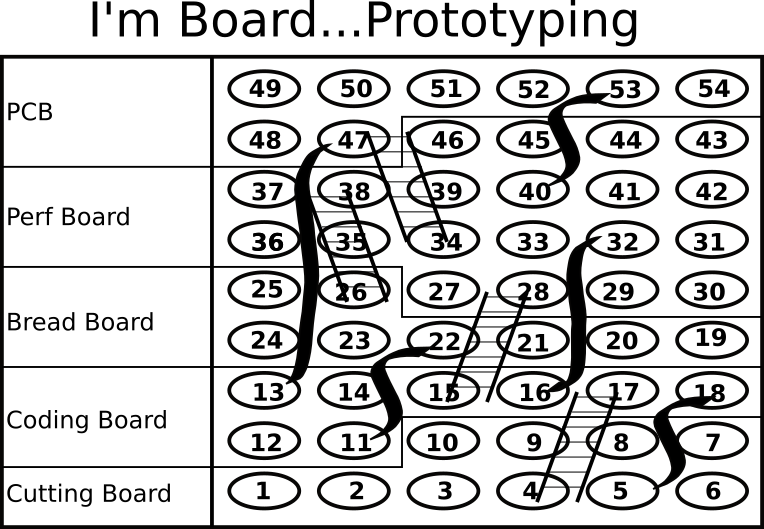

I currently working on a project for a local organization. I'm always looking for novel opportunities to exchange knowledge. Writing is my passion. I stumbled across the Circuit Prototype Techniques Challenge and thought maybe this project can fit?. After some reflection, I came up with a strategy to document this project using the criteria for the challenge. I have taken the project and divided the prototyping tasks into Boards. Each Board describes a Prototyping Techniques employed to reach the goal of designing a circuit board.

The process to develop and design a printed circuit board (PCB) is a lot like playing the game of Chutes & Ladders. The object is to step through the numbers to reach the final number. When you reach the final step the PCB should be ready for production. The numbers are divided along the different Boards that are described below. Along the path of steps are Chutes that take you back to lower steps to start over. The Ladders enable you to advance ahead steps.

From the Cutting Board, I completed the steps to get a drawing and then moved on to the Coding Board steps. In the Coding Board, I needed to go back and make changes in the drawing (i.e. I landed on a chute) to solve problems.

From the Cutting Board

The project goal is to automate the operation of a model train layout. The objective was to take an existing HO scale DC model railroad layout and automate the operation. The goal was to minimize the amount of user interaction. The first step was to napkin out an understanding of the operation. The napkin doodles started the prototyping process. A number of iterations of the napkin drawing produced a block diagram that explained the layout and its operation in simple terms. The block diagram became the focal point for communication between the client and designer.

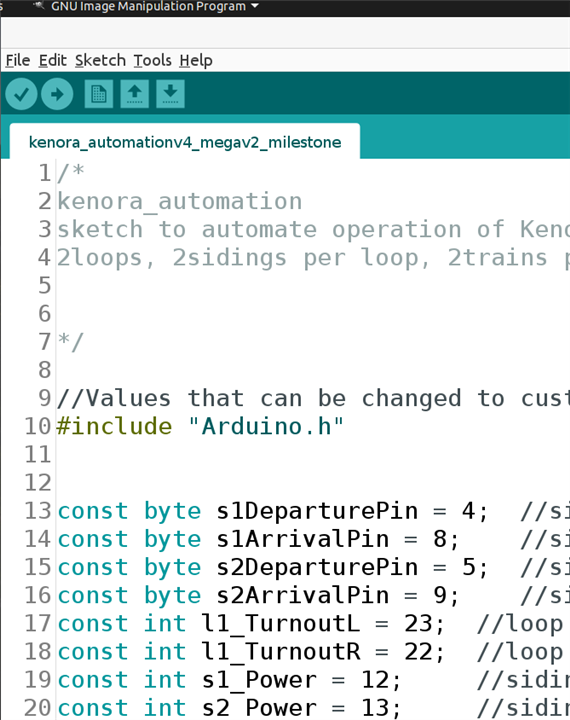

From the Code Board

Using the block diagram produced from the Cutting Board generate a code framework to automate the layout sequence. This Board uses the block diagram to help define the code to produce the desired outcomes. Producing the code defined the I/O requirements. The I/O requirements define the Arduino board requirements. Oh did I mention the project was going to use an Arduino?

From the Bread Board

This Board does some proof of concept. Does a circuit work? Assemble small circuits on breadboards using sensors and motors. The circuits would have to connect to the I/O's. It was necessary to confirm what was defined in the code can be supported in the physical world. An example: When the train moves across an IR sensor does it produce the desired output for the code to use.

The video display a railcar moving across a block of IR sensors. An LED turns on when the sensor is tripped. The position and sensitivity need to be determined on the layout for proper operation. One of the things this breadboarding demonstrated is that the gap in between cars is detected. It is impacted by the sensitivity of the sensor and the speed of the train.

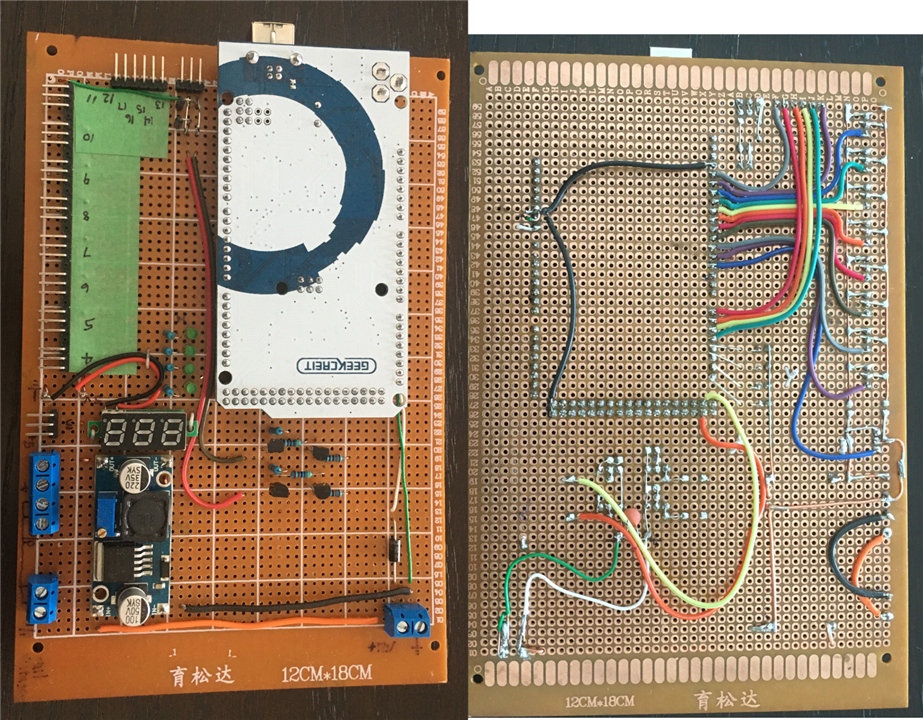

From the Perf Board

Using Perf board create a circuit board wired to the Arduino I/O and to the physical world. Establish connections and connectors to interface to the components that will be on the railroad layout. This has to generate a working model. This is the working prototype. The board may not be pretty but it works. It includes the infrastructure like power to run the electronics. This is where the block diagram now spawns a schematic drawing.

From the Printed Circuit Board

The results from the Perf Board provide the requirements to design the printed circuit board layout in Fritzing.

From the Charcuterie Board

With success comes rewards!

A number of prototyping techniques are used to design the printed circuit board. I'm currently testing the perf board. It has resulted in a few wiring changes, that have to be incorporated into the PCB. When testing of the Perf Board is complete I hope to wine and dine.