As an experimenting blog, this one was a bit of a failure, but I can at least use it to show the

prototyping technique that I'm most fond of.

As a guide, I'm using an Analog Devices article [1]. This suggests the use of a second op amp to servo

the first. Sounded good in theory but didn't work too well for me in practice. Here's what they propose

With the switch in the position shown the auxiliary op amp keeps the output of the DUT around 0V, give or

take a small offset of a few tens of uV. With the switch set to 1V the DUT output will have to move to

-1V to keep the centre of the R4/R5 divider at 0V. The change in voltage at the output of the aux op amp

between those two states is then 1001x the change at the input to the DUT and the gain can then be worked

out as the ratio of the change at the output to the change at the input. Simple! As if...

I don't have a 5uF capacitor but I do have a 10uF one so I'll use that and change the resistors to 100k

to keep the integrator time constant about the same. For the auxilliary op-amp I'm going to use an OP27.

Here's the board I'm going to build on.

As you can see it's recycled from some other experiment. The cutting between the pads was done with a

craft knife.

Here's an upside-down turned-pin IC socket showing how I place the decoupling capacitors underneath

between the supply pins with the excess lead then being the supply connection down to the pcb.

I won't go through the build step-by-step, but here are some pictures of the end result

A few tips from my experience so far of building boards like this:

1/ It's worth using a continuity setting on a multimeter to check that all the separate pads really are

separate. It's very easy to end up with a sliver of copper joining areas that shouldn't be joined.

2/ I use a magic marker pen to write on boards. Particularly things like supply voltages which would do

the most damage if subsequently connected wrongly.

3/ Large areas of copper will obviously need a soldering iron with a reasonable heat capacity if you're

going to solder to them. I generally manage ok with a 60W Weller iron and a fairly large 3.2mm chiesel

bit.

4/ For test points for probes, rather than a single wire sticking up I prefer to form a wire into a

triangle or square shape. It's more stable and you're less likely to have an accident with a probe tip or

ground clip shorting something else.

5/ Parts don't have to sit the conventional way up. When wiring directly to the pins of DIL ICs, it often

works better having the part inverted. In this case I can't do that because I wanted to be able to swap

both devices and had to use sockets.

6/ I tend to mix conventional and smd parts for the passives. Sometimes it's convenient to use

(reasonably large) smd parts between pads, sometimes it makes more sense to use conventional parts as

'bridges'.

7/ I've noticed that bright orange capacitors look really cool in photographs.

So does my circuit work? Short answer: no. Here's the output of the DUT

It oscillates nicely. Quite an acceptable sinewave really. With the integrator pole and the compensation

pole for the DUT fairly close together, it was always going to be a bit difficult. It doesn't oscillate

in the simulator (which is a good lesson in how you can't always rely on simulation with analogue

circuits - though, to be fair, they don't expect you to be doing design with a part operating open-loop),

but that doesn't help me with the real thing. Adding some resistance (680R) in series with the

integrator capacitor got it stable, but that then led to another problem.

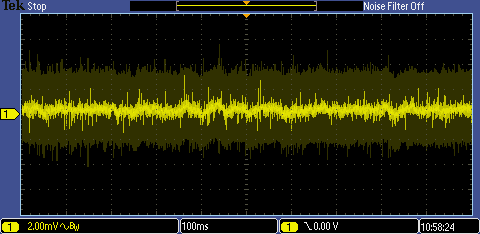

That's the output of the DUT and is the amplified low-frequency (1/f) noise from the op amp input.

Here is the output of the integrator (on AC, so we don't see the -60mV or so of dc offset, just the variation of it).

Whilst the integrator removes the very low frequency part and stops the output of the DUT from walking

too far away from zero, it can't deal so well with the somewhat higher frequency 1/f noise and that means

the small change I'm trying to measure is hidden within the meandering value I see on the meter.

There's also a further problem in that the offset voltage of the DUT seems to change with temperature as

the part heats and that seems to have a very long time constant. All a bit frustrating. Do I try and

refine this, or do I give up and try a different technique?

Just realised I need a video to enter the competition. This gives an idea of how the output of the integrator meanders around. This is actually from a later experiment with an OP27, where the noise that's driving that change is less, but it shows the problem with doing accurate measurements using this method.

[1] Simple Op Amp Measurements. James M. Bryant.

Analog Dialog, Volume 45, Number 2, 2011.

https://www.analog.com/media/en/analog-dialogue/volume-45/number-2/articles/volume45-number2.pdf

If you found this interesting and would like to see more blogs I've written, a list can be found here:

/members-area/b/blog/posts/jc2048-blog-index-new-version