I have made unserviceable two L293N and one L298N motor driver modules doing something but I don't know what. I would like to know what I did, so I can prevent it from happening in the future. Can anyone share their experience or knowledge to help me isolate the cause of these failures?

As part of the Automation Design Challenge I am developing a solution to raise the bridge on a model railroad layout.

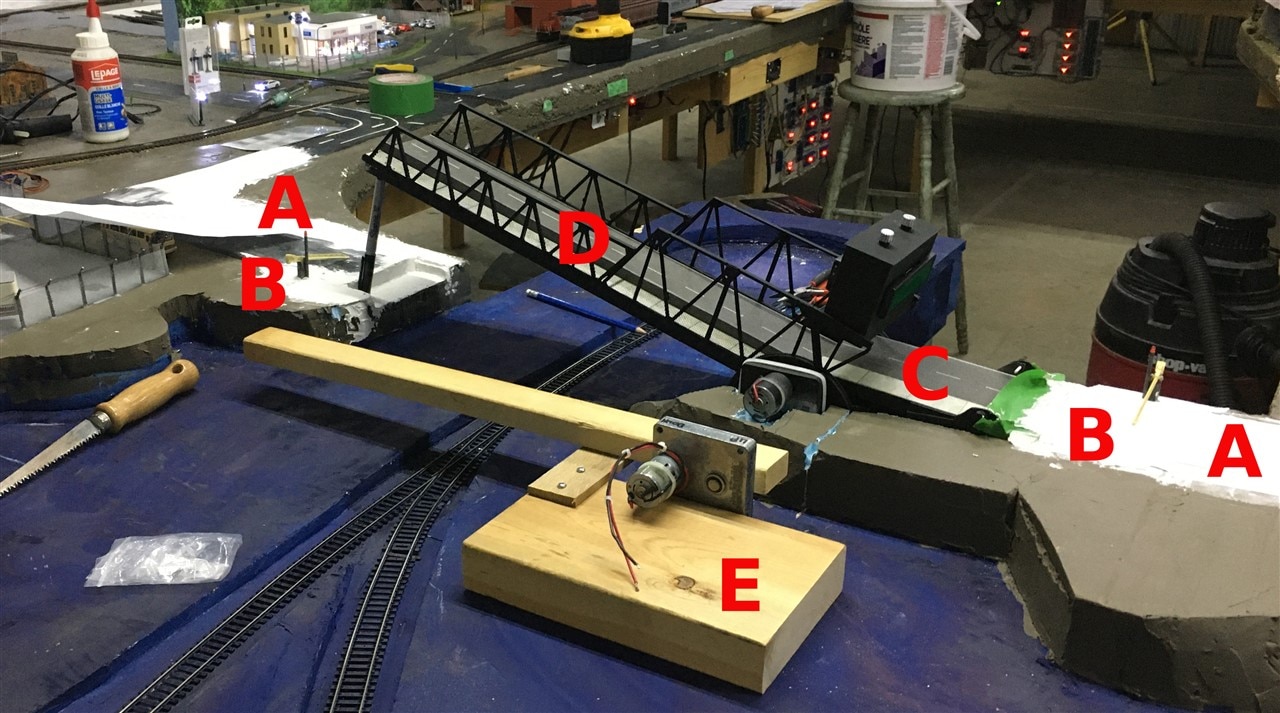

Model railroaders have been busy working on building the bridge. A magnet raised and lowered using a servo motor are located under the roadbed at points A. The barrier gates that are raised and lowered via servo are at points B. A ramp at point C is raised and lowered to make room for the bridge point D, to move is also controlled by a servo. The bridge has a separate motor to raise and lower it.

While the model railroaders are putting the finishing touches on the bridge installation, automation development continues. I built a bridge simulator point E using the same model of motor that is used for the bridge movement. My goal was to use the simulator to resurrect Arduino code that will manage the raising and lowering of the bridge.

In the past I have smoked electronics and had to tear apart the layout to make repairs. The simulator will hopefully eliminate that step:)

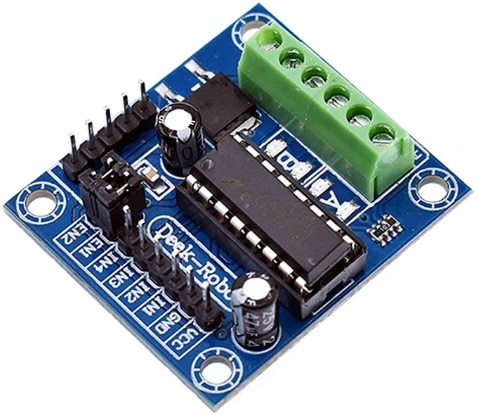

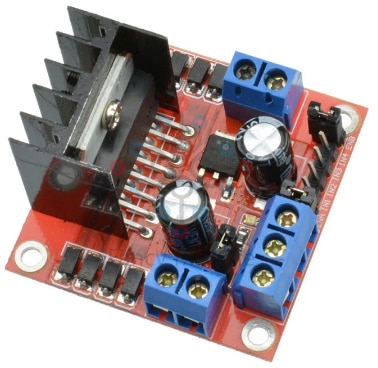

The test unit has the motor moving an arm, controlled by a Nano and switches (not shown in the picture). The Nano uses an L293N or L298N to drive the motor. I did about three hours of testing with an L293N module raising and lowering the arm before it didn't work anymore. I can’t recall doing anything that would result in the failure. I replaced the driver module and continued to test but once again I did something to cause it not to work.

I took the assembly home and continued to test (while watching the playoff hockey games) and discovered the failed modules are outputting a little less than a half of the motor supply voltage of 12V. I then tried a spare L298N module I had and performed some tests.

It initially worked. 12V was being outputted to the motor. At one point I prevented the arm from rising. I also noticed the module LED’s come on when I pushed the arm back down. The L298N didn’t work after that. Did the action of preventing the arm from rising or pushing it down, smoked the chips. I’m just not sure?

My speculation is either preventing the motor to raise the arm or pushing the arm down might have caused a back emf that damaged the driver chips. There is a possibility that this action may happen when the bridge goes into production. As you can see from the picture the bridge is exposed to operators.

I have worked with these driver modules in the past to control motor speed with no issue. In those scenarios, I wasn’t impeding the motor movement. I made some amateur mistakes (shite happens) like shorting outputs but the chips still worked.

I recall before damaging the first two L293N modules I did impede the motor by stopping the arm but no damage was apparent because I was able to continue testing. Maybe at low motor speed settings impeding the arm is not a problem but at max settings the chip is damaged. I’m not sure?

If anyone has any insights, suggestions or condolences please pass them along. I have no more spares at the moment so I have to park the project until a delivery truck arrives.

Top Comments