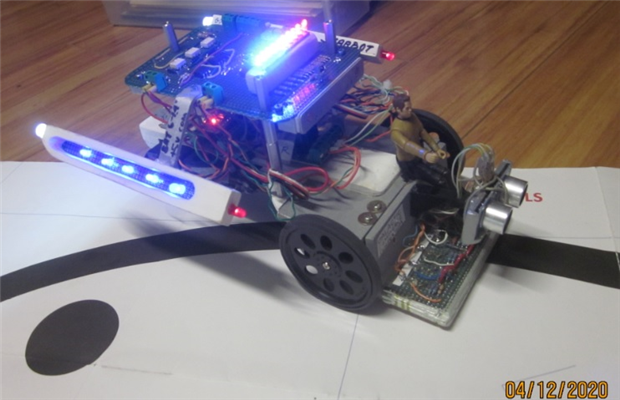

I had several old homemade robots that were out of date and needing maintenance.

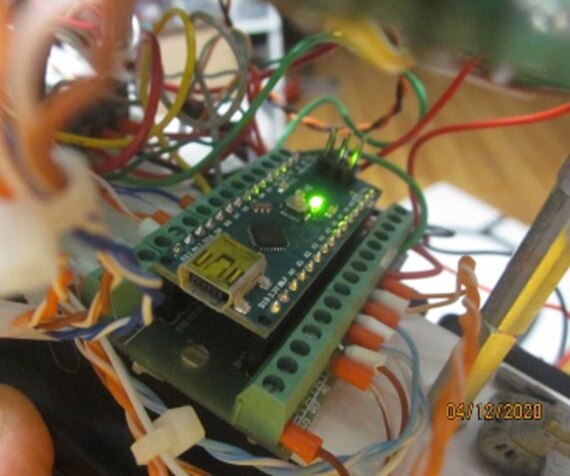

Thanks to NanoRama, the old robots have a new Arduino Nano brain and renewed life.

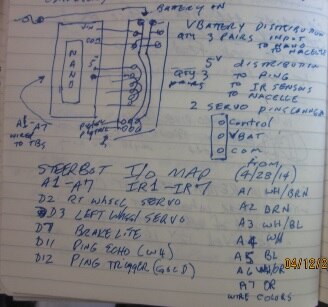

The Arduino Nano has analog IO which can be used to read the voltage across a IR phototransistor to determine how much IR is reflected off a white sheet of paper.

The white paper is a good reflector, black is a poor reflector of IR light.

That is how line following works in a nutshell.

Reading the phototransistor voltage analog allows the software to determine hysteresis and filtering of the detection signal, and also use a PID if wanting to ride on the edge of a black line.

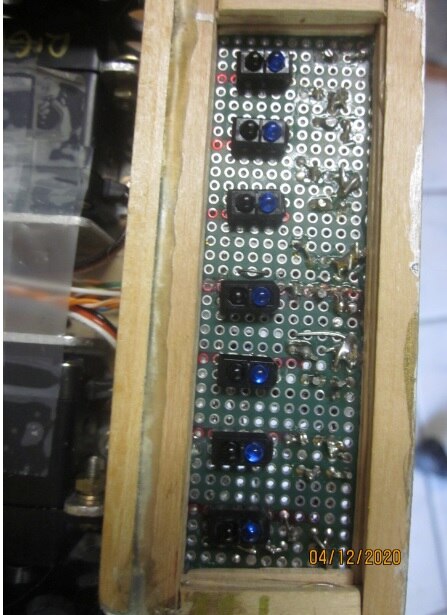

The Star Trek style nacelle IO card was originally built for a Parallax BoEbot. This card has a bunch of LEDS, which the higher power ones use opto couplers or SSRs to drive them. This card also has an IR receiver wired.

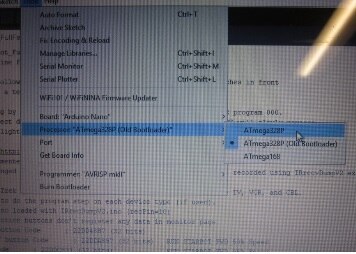

When using the Arduino Nano provided by this contest, the new bootloader in the Arduino IDE needs selected.

Without further adieu, here are photos, diagrams and code for the project.

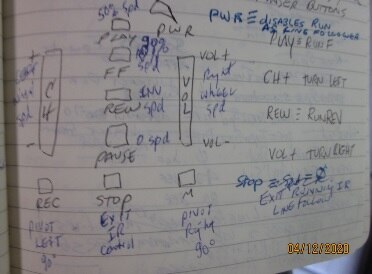

In my operation description, item 4 says select IR remote control or line follow per HW switch. That was simplified, just press ON on the remote controller to activate IR remote control mode.

Please reply to me if interested in the detailed schematics.

// Starbot_FullFeaturesWorks.ino includes both IRRemotecontrol

// and line follower control modes

//

//Line Follower mode, an object detected by PING less than 6 inches in front

//causes a temporary zerospeed condition

//

//Running by IR Remote control. Star Trek Phaser Remote, set VCR program 000.

//an object detected by PING less than 6 inches in front, STARBOT will slowly reverse

// and slightly steer right to find a clear path.

//

///from http://www.circuitbasics.com/arduino-ir-remote-receiver-tutorial/

// I commented out the LCD display part

// I changed the original values to the HEX values to the ones I recorded using IRrecvDumpV2 example.

//

// Star Trek Phaser Remote programmed with "000" code for device TV, VCR, and CBL.

// Need to do the program step on each device type (if used).

// Arduino loaded with IRrecDumpV2.ino (recPin=10)

// VCR action buttons don’t register any data in monitor page

// PWR button Code : 22DD48B7 (32 bits)

// PLAY button Code : 22DDA857 (32 bits) RUN STARBOT FWD 50% Speed

// FF Code : 22DDC837 (32 bits) RUN STARBOT FWD 95% Speed

// REW Code : 22DD9867 (32 bits) go REV INVERT In USE SPEED REFERENCES

// PAUSE Code : 22DD08F7 (32 bits) RUN ZEROSPEED

// STOP Code : 22DD28D7 (32 bits) Disable run from IR, i.e. run as line follower

// VOL+ Code : 20DF40BF (32 bits) Inc Right wheel speed

// VOL - Code : 20DFC03F (32 bits) DEC Right wheel SPEED

// Ch + Code : 22DDD827 (32 bits) Inc left wheel spd

// Ch - 22DDF807 (32 bits) dec left wheel speed

// REC Code : 22DD18E7 (32 bits) PIVOT 90 degrees left

// MUTE Code : 20DF906F (32 bits) Pivot 90 degrees right

//

//

#include <IRremote.h>

#include <Servo.h>

const int RECV_PIN = 10;

IRrecv irrecv(RECV_PIN);

decode_results results;

unsigned long key_value = 0;

Servo LeftWheel; // create servo object to control a servo

// a maximum of eight servo objects can be created

Servo RightWheel; // create servo object to control a servo

// a maximum of eight servo objects can be created

int RunByIRRemote = LOW;

int LeftSPD =90 ; //var for left side wheel speed

int RightSPD =90; //var for RHS wheel speed

int RightSpeedInUseValue = 90;

int LeftSpeedInUseValue = 90;

//// setup needed VARS --------------------------

// pinging VARs

unsigned long Pingmicroseconds =0;

unsigned long PingDistanceInches =0;

int PreviousPingDistanceInches;

int pos = 0; // variable to store the servo position

unsigned int Ping_cm; // ping distance in cm

int loopNR=0; // generic register for loops

//********

int WheelRunSpd=45; // full speed setpoint for robot 0 is zerospeed, 90 is top speed

int HardTurnWheelSpd=5;// speed setpoint of wheel that slows down to make a hard pivot turn, 0 is zerospeed, 90 is top speed

int GentleTurnWheelSpd=25;// speed setpoint of wheel that slows down to make a normal turn , 0 is zerospeed, 90 is top speed

//****

int arrayvalue=0;

int IR_Analog[8]; // analog input 0 is unused, array for the IR sensors analog value

int IR_bits[8]; // analog input 0 is unused, array for the IPR sensors analog converted to bits

void setup(){

// Serial.begin(9600);

irrecv.enableIRIn();

// irrecv.blink13(true);

RightWheel.attach(2); // attaches the servo on pin 2 to the servo object

LeftWheel.attach(3); // attaches the servo on pin 3 to the servo object , 0 = left front wheel forward

pinMode(4,OUTPUT); // Left Turn LEDs on nacelle P1, 5V to turn on, powered from Vbat

pinMode(5,OUTPUT); // right Turn LEDs on nacelle P2 , 5V to turn on, powered from Vbat

pinMode(6,OUTPUT); // rear brake LEDs on nacelle P3 , 5V to turn on, powered from Vbat

pinMode(7,OUTPUT); // warp drive LEDs on nacelle P4, 5V to turn on, powered from Vbat

pinMode(9,OUTPUT); // police bar LEDs on nacelle P7 ,5V to turn on, powered from Vbat

pinMode(13,OUTPUT); // police bar LEDs on nacelle P6, 5V to turn on, powered from Vbat

// note: pin10 is used by IRRemote.

pinMode(12, OUTPUT); // PING trigger

pinMode(11, INPUT); // PING echo

//

//pinMode(A0,INPUT); //

// // A1-A7 are wired with TRT2000 IR sensors,

pinMode(A1,INPUT); // voltage drop across IR senstive LED circuit. Low number is IR transistor ON (see white reflection)

pinMode(A2,INPUT); // High value - i.e. no light, more voltage drop (black line or no white paper)

pinMode(A3,INPUT); //

pinMode(A4,INPUT); //

pinMode(A5,INPUT); //

pinMode(A6,INPUT); //

pinMode(A7,INPUT); //

// IO Test before starting --------------------------

digitalWrite(4,HIGH);

delay (200);

digitalWrite(4,LOW);

digitalWrite(5,HIGH);

delay (200);

digitalWrite(5,LOW);

digitalWrite(6,HIGH);

delay (200);

digitalWrite(6,LOW);

digitalWrite(7,HIGH);//naccelle

delay (200);

digitalWrite(7,LOW);

digitalWrite(13,HIGH);

delay (200);

digitalWrite(13,LOW);

digitalWrite(9,HIGH);

delay (200);

digitalWrite(13,LOW);

digitalWrite(9,LOW);

}

void PING ()

{

digitalWrite(12, HIGH); // HC-SR04 pulse high TRIGGER

delayMicroseconds(10); // pauses for 10 microseconds

digitalWrite(12, LOW); // sets the TRIGGER pin off

// ECHO PIN measure microseconds taken to hear pulse, third number is wait time in microseconds( unsigned long int 0 to 4,294,967,295)

Pingmicroseconds = pulseIn(11, HIGH, 4000);

PingDistanceInches = (Pingmicroseconds/149); //formula from HC-SR04 spec sheet , assume solution is an integer

if (PingDistanceInches==0){PingDistanceInches=111;}

// 340 meters/ second * (39.37 inches per meters) =13385. inches per usec = .0133856 inches per microsecond;; 74.7 usecs/inch , multiply by 2 for send/return path

// test and debug

// Serial.print("PingDistance=");

//// Serial.print(PingDistanceInches);

// Serial.print("inches ");

// Serial.println();

}

void loop()

{

if (irrecv.decode(&results))

{

if (results.value == 0XFFFFFFFF)

results.value = key_value;

// lcd.setCursor(0, 0);

// lcd.clear();

switch(results.value){

case 0x22DD48B7: ///

// Serial.println("PWR Button Pressed");

RunByIRRemote = HIGH;

break;

case 0x22DDA857: //// if PLAY button pressed, STARbot speed ref is 50% forward

// Serial.println("Pressed PLAY");

if (RunByIRRemote == HIGH){

RightSPD =(115); // WheelRunSpd counts above 90, 90 is zero , +180 is full spd Fwd

LeftSPD =(65); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

digitalWrite(7,HIGH);//naccelle

}

break;

case 0x22DDC837 : //// if FF button pressed, STARbot speed ref is 95% forward

// Serial.println("Pressed FF");

if (RunByIRRemote == HIGH){

RightSPD =(135); // WheelRunSpd counts above 90, 90 is zero , +180 is full spd Fwd

LeftSPD =(45); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

digitalWrite(7,HIGH);//naccelle

}

break;

case 0X22DD9867 : // if REW button pressed, STARbot in use speed ref is reversed

// Serial.println("Pressed REW");

if (RunByIRRemote == HIGH){

RightSpeedInUseValue = RightSPD;

LeftSpeedInUseValue = LeftSPD;

RightSPD = (90-(RightSpeedInUseValue-90)); // WheelRunSpd counts above 90, 90 is zero , +180 is full spd Fwd

LeftSPD =(90+(90-LeftSpeedInUseValue)); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

if (RightSPD <0) {RightSPD=0;} // limit the max value

if (RightSPD >180) {RightSPD=180;} // limit the max value

if (LeftSPD <0) {LeftSPD=0;} // limit the max value

if (LeftSPD >180) {LeftSPD=180;} // limit the max value

}

break;

case 0x22DD08F7:

// if Pause button pressed, STARbot speed ref is zeroed

// Serial.println("PAUSE");

if (RunByIRRemote == HIGH){

RightSPD =(90); // WheelRunSpd counts above 90, 90 is zero , +180 is full spd Fwd

LeftSPD =(90); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

digitalWrite(7,LOW);//naccelle

}

break ;

case 0x22DD28D7: // if STOP button pressed, STARbot control by phaser is disabled

// Serial.println("STOP PB");

RunByIRRemote = LOW;

//digitalWrite(7,LOW);

break ;

case 0x20DF40BF: // if VOL+ button pressed, STARbot increases right wheel speed

// Serial.println("VOL+");

if (RunByIRRemote == HIGH){

RightSPD =(RightSPD+5); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

if (RightSPD <0) {RightSPD=0;} // limit the max value

if (RightSPD >180) {RightSPD=180;} // limit the max value

}

break ;

case 0x20DFC03F : // if VOL- button pressed, STARbot decreases right wheel speed

// Serial.println("VOL MINUS");

if (RunByIRRemote == HIGH){

RightSPD =(RightSPD-5); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

if (RightSPD <0) {RightSPD=0;} // limit the max value

if (RightSPD >180) {RightSPD=180;} // limit the max value

}

break ;

case 0x22DDD827 : // if CH+ button pressed, STARbot increases left wheel speed

// Serial.println("CH+");

if (RunByIRRemote == HIGH){

LeftSPD =(LeftSPD-5); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

if (LeftSPD <0) {LeftSPD=0;} // limit the max value

if (LeftSPD >180) {LeftSPD=180;} // limit the max value

}

break ;

case 0x22DDF807 : // if CH- button pressed, STARbot decreases left wheel speed

// Serial.println("CH minus");

if (RunByIRRemote == HIGH){

LeftSPD =(LeftSPD+5); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

if (LeftSPD <0) {LeftSPD=0;} // limit the max value

if (LeftSPD >180) {LeftSPD=180;} // limit the max value

}

break ;

case 0x22DD18E7 : // if REC button pressed, STARbot pivots left

// Serial.println("REC");

if (RunByIRRemote == HIGH){

RightSpeedInUseValue = RightSPD; // temporarily save values in use

LeftSpeedInUseValue = LeftSPD; // temporarily save values in use

RightSPD =(135); // WheelRunSpd counts above 90, 90 is zero , +180 is full spd Fwd

LeftSPD =(90); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

RightWheel.write(RightSPD); // wired to D2 , 0 is full speed fwd, run @ 7/9 of top speed to allow for overspeed

LeftWheel.write(LeftSPD); // wired to D3, // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

delay (1000);

RightSPD = RightSpeedInUseValue ; // restore spd values to before pivot command

LeftSPD = LeftSpeedInUseValue ; // restore spd values to before pivot command

}

break ;

case 0x20DF906F : // if MUTE button pressed, STARbot pivots right

// Serial.println("MUTE");

if (RunByIRRemote == HIGH){

RightSpeedInUseValue = RightSPD; // temporarily save values in use

LeftSpeedInUseValue = LeftSPD; // temporarily save values in use

RightSPD =(90); // WheelRunSpd counts above 90, 90 is zero , +180 is full spd Fwd

LeftSPD =(45); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

RightWheel.write(RightSPD); // wired to D2 , 0 is full speed fwd, run @ 7/9 of top speed to allow for overspeed

LeftWheel.write(LeftSPD); // wired to D3, 180 is full speed fwd run @ 7/9 of top speed to allow for overspeed

delay (1000);

RightSPD = RightSpeedInUseValue ; // restore spd values to before pivot command

LeftSPD = LeftSpeedInUseValue ; // restore spd values to before pivot command

}

break ;

}

key_value = results.value;

irrecv.resume();

} // end of IR Receiver case logic

////continuance of loop execution after IR remote scan is completed

//// if RunByRemote is LOW, the line folllower code will execute

if (RunByIRRemote == LOW )

///while (RunByIRRemote == LOW)

{

/// read all the IR sensors & store in an array

IR_Analog[1]= analogRead(A1); // read the input pin

IR_Analog[2]= analogRead(A2); // read the input pin

IR_Analog[3]= analogRead(A3); // read the input pin

IR_Analog[4]= analogRead(A4); // read the input pin

IR_Analog[5]= analogRead(A5); // read the input pin

IR_Analog[6]= analogRead(A6); // read the input pin

IR_Analog[7]= analogRead(A7); // read the input pin

for(loopNR = 1 ; loopNR < 8; loopNR += 1) // read all the IR line detectors

{

// this converts the analog value to a bit value with hysterysis and stores that result in another array

if (IR_Analog[loopNR]<200) {IR_bits[loopNR]=0;} ///value == 0 white

if (IR_Analog[loopNR]>600) { IR_bits[loopNR]=1;} ///value== 1, black

// Serial.print ("IR");

// Serial.print (loopNR);

// Serial.print ("=");

// Serial.println (IR_Analog[loopNR]);

// Serial.print ("IRbit = ");

// Serial.println (IR_bits[loopNR]);

// delay (10);

}

arrayvalue = 0; //clear out that VAR last value

//// read analog ins, convert bits, then construct a 7 bit word. Spreadsheet IRSensorMeasurements.xlsx provides mapping of values VS steer action

arrayvalue = ((IR_bits[1]*1)+ (IR_bits[2]*2)+(IR_bits[3]*4)+ (IR_bits[4]*8)+(IR_bits[5]*16)+(IR_bits[6]*32)+(IR_bits[7]*64));

// these line reading values have the wheels go the same speed

if ((arrayvalue == 8) || ((arrayvalue >19)&& (arrayvalue <24)) || ((arrayvalue >27)&& (arrayvalue <32)) || ((arrayvalue >43)&& (arrayvalue <48)) || (arrayvalue ==65) ||((arrayvalue >96)&& (arrayvalue <104)) || (arrayvalue == 126))

{

digitalWrite(4,LOW);//left turn signal off

digitalWrite(5,LOW);//right turn signal off

RightSPD = (90+WheelRunSpd); // WheelRunSpd counts above 90, 90 is zero , +180 is full spd Fwd

LeftSPD=(90-WheelRunSpd); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd rev

// Serial.print ("IR follower array value = ");

// Serial.println (arrayvalue);

// Serial.println ("go forward");

// delay(30);

digitalWrite(7,HIGH);// turn on nacelle lights

}

// these line reading values make a HARD left turn, left wheel slows way down, right wheel keeps up speed if arrayvalue = 1,2 or 3

else if ((arrayvalue >-1)&&(arrayvalue<4))

{

RightSPD =(90+WheelRunSpd); // WheelRunSpd counts above 90, 90 is zero , +180 is full spd Fwd

LeftSPD =(90-HardTurnWheelSpd); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

digitalWrite(4,HIGH);//left turn signal on

// Serial.print ("array value = ");

// Serial.println (arrayvalue);

// Serial.println ("hard left");

delay(10);

digitalWrite(4,LOW);//left turn signal off

}

// these line reading values make a left turn, left wheel slows , right wheel keeps up speed

else if (((arrayvalue >3)&&(arrayvalue<16)) || ((arrayvalue >31)&&(arrayvalue<44))||((arrayvalue >63)&&(arrayvalue<80))||((arrayvalue >122)&&(arrayvalue<127)))

{

RightSPD =(90+WheelRunSpd); // WheelRunSpd counts above 90, 90 is zero , +180 is full spd Fwd

LeftSPD =(90-GentleTurnWheelSpd); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

digitalWrite(4,HIGH);//left turn signal on

// Serial.print ("array value = ");

// Serial.println (arrayvalue);

// Serial.println ("hard left");

//delay(30);

digitalWrite(4,LOW);//left turn signal off

}

//stop the wheels if only see white or only see black, mens the robot is not on a line

else if ((arrayvalue == 0)||(arrayvalue == 127)) ////dumbass forgot == again

{

digitalWrite(4,LOW);//left turn signal off

digitalWrite(5,LOW);//right turn signal off

RightSPD=90;

LeftSPD=90;

// Serial.print ("array value = ");

// Serial.println (arrayvalue);

// Serial.println ("STOP");

//delay(30);

digitalWrite(7,LOW); // turn off nacelle lights to indicate off track condition

digitalWrite(6,HIGH); //D6 are brake LEDs

delay(2000);

digitalWrite(7,HIGH);// turn on nacelle lights

digitalWrite(6,LOW); //D6 are brake LEDs

delay(300);

}

// these line reading values make a HARD RIGHT turn, right wheel slows way down, left wheel keeps up speed if arrayvalue = 32,64,80,96

else if ((arrayvalue ==32)||(arrayvalue=64)||(arrayvalue ==80)||(arrayvalue=96))

{

RightSPD =(90+HardTurnWheelSpd); // WheelRunSpd counts above 90, 90 is zero , +180 is full spd Fwd

LeftSPD =(90-WheelRunSpd); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

digitalWrite(5,HIGH);//right turn signal on

// Serial.print ("array value = ");

// Serial.println (arrayvalue);

// Serial.println ("hard left");

delay(10);

digitalWrite(5,LOW);//right turn signal off

}

else // these line reading values make a right turn, right wheel slows down , left wheel at runspeed BUT if a value fails this turns right

{

RightSPD =(90+GentleTurnWheelSpd); // WheelRunSpd counts above 90, 90 is zero , +180 is full spd Fwd

LeftSPD=(90-WheelRunSpd); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd rev

digitalWrite(5,HIGH);//right turn signal on

//Serial.print ("array value = ");

//// Serial.println (arrayvalue);

// Serial.println ("hard right");

delay(10);

digitalWrite(5,HIGH);//right turn signal off

}

}

// ** PING for obstruction while running as an line follower,

// the ping stops the robot while there is an obstruction in

// front of it. Whn obstruction is removed, then it continues on **

PING();

if ((PingDistanceInches<6)&(PreviousPingDistanceInches<6))

{

if (RunByIRRemote==LOW)///if running linefollower mode , robot needs to stop

{

RightWheel.write(90); // wired to D2 , 0 is full speed fwd, run @ 7/9 of top speed to allow for overspeed

LeftWheel.write(90); // wired to D3, 180 is full speed fwd un @ 7/9 of top speed to allow for overspeed

LeftSPD = 90;

RightSPD = 90;

}

if (RunByIRRemote==HIGH)///if running IRRemote mode , robot needs to back up and turn slightly

{

RightSpeedInUseValue = RightSPD; // temporarily save values in use

LeftSpeedInUseValue = LeftSPD; // temporarily save values in use

RightWheel.write(85); // wired to D2 , 180 is full speed fwd, run @ 7/9 of top speed to allow for overspeed

LeftWheel.write(100); // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

LeftSPD = 100;

RightSPD = 65;

}

for (int i=1; i<10; i++)

{

digitalWrite(4,LOW);//left turn signal off

digitalWrite(5,LOW);//right turn signal off

//

digitalWrite(6,HIGH); //D6 are brake LEDs

digitalWrite(13,HIGH); //D13 police LEDs red/blue

digitalWrite(9,LOW); //D9 police LEDs blue/red

delay (150);

digitalWrite(13,LOW);

digitalWrite(9,HIGH);

delay (150);

}

digitalWrite(6,LOW);

digitalWrite(9,LOW);

if (RunByIRRemote==HIGH)

{RightSPD = RightSpeedInUseValue ; // restore spd values to before pivot command

LeftSPD = LeftSpeedInUseValue ; // restore spd values to before pivot command

}

}

PreviousPingDistanceInches = PingDistanceInches;

/////////end of stop when object pings too close

// Serial.print ("RunByIRRemote flag= ");

// Serial.println (RunByIRRemote);

// Serial.print ("LeftSPD = ");

// Serial.println (LeftSPD);

RightWheel.write(RightSPD); // // WheelRunSpd counts above 90, 90 is zero , +180 is full spd Fwd

LeftWheel.write(LeftSPD); // wired to D3, // WheelRunSpd counts below 90, 90 is zero, 0 is full spd reverse

}

Top Comments

-

dubbie

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

robogary

in reply to dubbie

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

dubbie

in reply to robogary

-

Cancel

-

Vote Up

+1

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

robogary

in reply to dubbie

-

Cancel

-

Vote Up

+3

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

robogary

in reply to dubbie

-

Cancel

-

Vote Up

+1

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

robogary

in reply to dubbie

-

Cancel

-

Vote Up

+1

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children