PREFACE:

For 40+ years, I've heard the same thing from wimpy-wrenchers - "They design cars so you can't work on them any more." I even hear this from fellow engineers. Actually, it's very much the opposite for reasons I'll present in this blog. I'm breaking that cycle of deceit with my son - ensuring he's not a wimpy-wrencher that buys into excuses to not raise a hood and base his common sense solely on his phone use. For the Project 14 Restoration & Repair challenge, we'll troubleshoot a faulty cab air blower with just a volt meter.

TABLE OF CONTENTS

|

|

INTRODUCTION

Having been working on cars now for 30+ years, I've found cars have never been more fun to work on as they are now. Here is why:

- Vehicles have never been more reliable - this keeps most maintenance including wheel bearings and ball joints in the preventive category versus a stressful roadside breakdown.

- Parts have never been more readily available - All parts needed under 200,000 miles are available now - same day pickup, next day delivery. Autozone, Advanced Auto Parts, O'Reilley's, RockAuto.com, Napa, to name a few. They will even change your filters and batteries for free. Also, you can get fully rebuilt engines and transmissions ready to swap in 3 days (since 1942! https://www.jasperengines.com/)

- Parts have never been cheaper - salvage yards now strip and warehouse parts and put them in a national database (car-part.com). You can get $1000 brain boxes (which probably won't fail in 30 years) for <$300. In general, it's hard to find a single part that costs more than $100.

- Parts have never been easier to figure out what you need - the online stores will ensure the right part matches your vehicle. You can google full Bill of Materials documents with exploded views for your vehicle that gives you every darn part number. Also, digital engine codes, not melted wires, point right to the problem.

- Vehicles have never been easier to diagnose - in the 80's, an old timey needle sweeping voltmeter would sweep out morse code for your engine codes. In the 00's you just switched your ignition three times. You don't have to check valve-to-cam lobe clearances, distributor points, ignition timing, carburetor jets, or distributor rotor fouling. ODB computer communication tools are under a couple hundred bucks. Autozone will pull your codes for free. All others problems are usually just an air filter being clogged if you've kept up with the 7 year swap on bearings and joints.

- It's never been easier to obtain "how to" references - for decades, Hanes and Chilton's have given complete teardowns with pictures and schematics. With a little Googling, you can find the full shop service manual with every detail. But the biggest thing today - some 11 year old on YouTube has already fixed it and shows you how to do it.

- Restoring a vehicle has never been cheaper - in the 90's they finally started doing a good job painting and sealing the inside of fenders, doors, and quarter panels. In turn, no matter where the vehicle was owned, it's rare to become a rust bucket. Everything else is either bearings, brakes, or solid state devices. So, every 7 years, you can swap a bunch of parts for under $800 bucks and totally restore your vehicle's ability to roll, stop, and bounce like new.

- Tools have never been more readily available and affordable - back in the day, you had to wait for the very expensive Snap-on truck to come buy to showcase their latest specialty tools. There are now websites such as www.toolsource.com dedicated to specialty automotive tools that are extremely affordable. Complete wrench sets that will last a lifetime with a lifetime warranty can be purchased at half the price you could get them back in the 80's. In general, with the money you save fixing things yourself, you can buy a complete wrench and ratchet set with the savings in one brake job!

- Engines and fuel trains have never been cleaner - advancements in lubricants and fuel additives have made engines stay cleaner for years. Things like fouled plugs and carbs, carbon scored cylinders, burnt rings, gummed up valves, worn valve seats, spent crank bearings are a thing of the past in vehicles under 150000 miles. It takes 200,000 miles to dirty up an engine that used to happen in under 100,000. So, when working on a car, you aren't doing it just because the products you run through it are gumming it, but to restore it beyond its original performance in horsepower and mpg.

The biggest thing the automotive industry uses that propagates the idea that you can't work on a vehicle is fear. If you buy into their (and other wimpy-wrenchers) excuses not to work on a car, you need to look in the mirror and ask yourself - are you afraid of causing more cost if you tried to fix it - is that why you don't even open the hood or jack it up? Normally, vanity is used to con your money, but for maintenance on home and vehicle, it's fear. Fear comes from lack of confidence. Lack of confidence is due to lack of hands on experience. Lack of experience is due to big auto giving you a self-justifiable excuse with their warranties. In turn, the masses have prescribed to what they are dishing out. However, warranties are just a sales gimmick - they have the data to know its an incredibly safe bet for them. But, if you overcome your fear, you can get a vehicle with 30K-75K miles with the exact features and build at 1/2 the sticker value of new.

Now, some would say spending the thousands extra to get a warranty gives you piece of mind - which is priceless. I contend that you can build such confidence for free, so why be a chump and pay thousands to buy it? Also, many warranty's are transferable in the first 5 years!

Now - I do concede - if you've paid your dues in your early years and have been there and done that on keeping your car on the road - heck, yea, pay that kid to fix it and be sure to keep him honest. Or, if you are bless in life with privilege or inheritance - ignore this proposal - use your time for more noble things, no doubt (that doesn't include Netflix). Both of you, just don't spread the myth and fear that cars are designed to not be worked on - you'll contribute to the onset of Idiocracy. Now, if you are one just getting a footing in this world, want to take on a life of building the ultimate toolbox, and are one desiring to acquire the true "common sense" by the definition of our forefathers, read on.

Here's a video from my son a few years back that will give you everything you need to know to wrench turn:

BLOWER PROBLEM

Due to the pandemic grounding us, we're doing a lot preventive maintenance this week on our Jeep. They had a 20% discount and free next day shipping on parts, so we thought it would be good to reset some of the consumables for another 4 years. By consumables, I mean things that rotate, turn, slide, or clog. These typically have a life under 7 years. We are changing out brake pads, rotors, all drive train bushings, sway bar links, water pump, thermostat, air filter, rear axle bearings, serpentine belt, and the engine oil and filter. Other joints and bearings such as on the front suspension were already renewed in the last 5 years, so we figured that's a good scope to keep us from going stir crazy in quarantine.

Since that scope is mechanical, I won't cover them here. We'll do a deep dive on failed blower for my heat and Air Conditioning.

Here is how it went down:

- First sign: heard a ticking sound under the dash where the blower is.

- Second sign: it no longer spun when turned on. no sound at all

- Suspected: After 21 years, the motor brushes have eroded to their springs which led to the ticking sound which then led to the ultimate failure.

So, we got after it. Here were the steps:

Checked the Fuse: This is quick and easy The fuses are labelled on the fuse block cover.

All was good, so we went to the other side of the electron path. The blower.

With Young Eyes - One Can Check a Fuse Visually, but an Ohmmeter gets a 100% check

Holding his tongue right, Connor snapped the electrical harness off the blower and checked for voltage.

This eliminates the chance of the problem being anywhere between the fuse and here.

There was voltage at the harness.

The 21 year old blower has bit the dust.

The blower fasteners were amazing!

You could use a flat screw driver, a torques bit, OR a 8mm socket -

and there were only 3 screws!

Took less than 5 minutes to drop it out.

Since we could just replace a 21 year old blower with a next day delivered blower for $60, we just bought a new one.

But, we wanted to see if it was the brushes, so we tore the motor apart.

We found the brushes were still had some years left!

The springs were still intact.

Let's look at what could have caused it to no longer work:

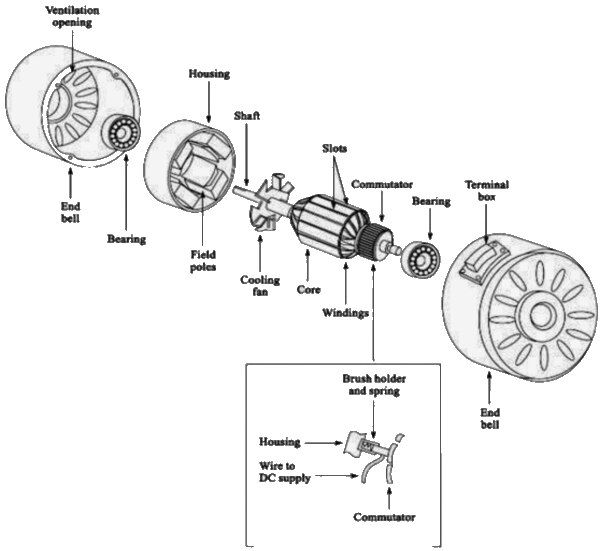

Exploded View of a DC Motor

End Bells - these are just a cover that provides structure for it to spin. They didn't appear to be damaged which could have led to a short, but not in this case.

Bearings - we could spin the motor easily by hand without resistance. Bearings are always good to renew when aged, but not what caused it to stop turning on.

Housing - since this is a stationary part, I would only expect corrosion to be a culprit. It had none.

Shaft and cooling fan - this would have had to been bent or damaged - not found in our case.

Brushes - this is the leading cause of motor failure in my experience. The brushes eventually erode to nothing and it rides on the springs that gave them tension. In a critical operation, you would periodically check them and renew. But, to my surprise, this was not the cause of failure.

Windings - this is most likely the problem. The windings have a copper wire that has an enamel coating on them. If this degrades, it is game over.

Checking Windings:

Windings can be tested for a "go, no go" with an ohmmeter set to measure resistance. You'd need a data sheet for the exact motor to do any further diagnostics. To check for potential future failures, you can use a device called "megger". Megger is actually a company name that had the most popular motor insulation testing equipment. Back in the day, you actually hand cranked them to induce a voltage that then could find the smallest of insulation issues.

PROJECT SUMMARY

Good news, no wires were melted or knobs found broken. The new blower is working great.

Working in the garage is always great time spent. You learn critical thinking skills and develop a good feel for things such as torqueing by hand without stripping out threads. You also develop confidence to take on any challenge in life. If you enter an engineering or technical field, you'll have the necessary feel for how things work in general and not be "that guy" when you open your mouth. Most of those guys don't even know they are "that guy".

If you are a Maker and like to breadboard and code, but never lift a hood, you have the necessary drive to get mechanical skills. Consider making a bucket list of wrench skills to put in your confidence bank and grow as an engineer. Here's where I'd start:

- Change oil and filter

- Pull and inspect fuses

- Rotate tires

- Change brake pads or shoes

- Change rotors

For bigger mojo, you should tackle these:

- Change automatic transmission fluid

- Change transaxle fluid

- Change ball joints

- Change tie-rod ends

- Changes Shocks and Struts

- Change rear axel bearings

- Change front hubs

With these, you'll be able to keep a vehicle in great shape for 25+ years. Over the decades, you will save tens of thousands of dollars, pay off your mortgage early, and get a head start on your kid's college fund. Also, you will be in the proud, but ever shrinking, club of those who says they love automobiles, but can actually work on one. Also, when the world needs N95 masks, you'll already have a stash, because what true, non-wimpy wrencher doesn't?

Stay safe!

Sean

Top Comments

-

dubbie

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

dubbie

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children